11

Models 150, 152, 162, 168 Important: To the Operator

Push-Button Switch

If an overload condition occurs, the freezer will

automatically stop operating. To pr operly reset the

freezer, place the toggle switch in the “OFF” position.

W ait two or three minutes; then press the push-button

switch. Place the power switch in the “WASH” position

and observe the freezer’s performance; place the

power switch in the “AUTO” position.

Note: If the freezer is unplugged from the wall

receptacle, it will be necessary to press the

push-button switch for the freezer to oper ate once

power is re-established.

Power Switch

The center position is “OFF”. The left position is

“WASH” which activates the beater motor only. The

right position is “AUTO”, which activates the beater

motor and the refrigeration system.

Temperature Control

The Models 150 and 152 use a temperature control to

monitor the product in the freezing cylinder . T urning

the adjusting knob clockwise will decrease the

product temperature. Turning the adjusting knob

counterclockwise will increase the temperature.

Each quarter of a turn will vary the temperature

approximately two degrees. DO NOT set the

temperature control colder than 18_F (-8_C). Should

you set the temperature colder than 18_F (-8_C),

premature failure of the belts and of the beater motor

may occur.

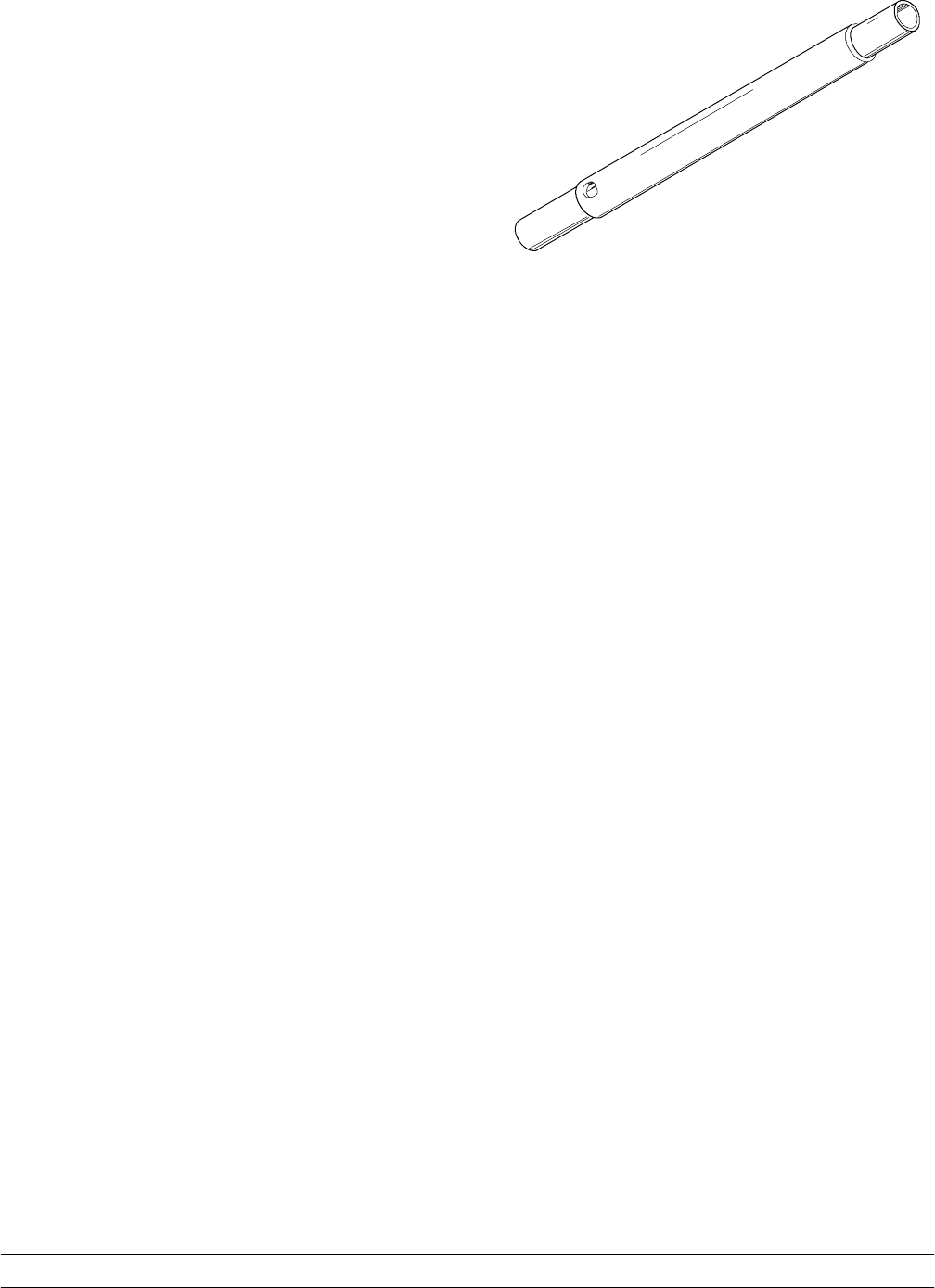

Air Tube

The m odels 150, 152, 162 and 168 are called upon to

handle a large variety of products (i.e., soft serve,

yogurts, Italian ices, sherbets, etc.). Thus, the

consistency of the mix you use will vary. The air tube

meters a combination of mix and air into the freezing

cylinder. If not enough mix enters the freezing cylinder,

a freeze-up may occur, which will cause eventual

damage to the beater. Depending upon the product

being run, you may wish to contact your local

authorized Taylor Distributor to make a slight

adjustment in the air tube.

Figure 2

Note: During “AUTO” operation, the orifice end of the

tube should b e inserted in the hole in the hopper.

Taylor Quality Control

The Models 162 and 168 us e a solid state control

called the T.Q.C. The purpose of this solid state control

is to sense the viscosity (thickness) of the product in

the freezing c ylinder. With the power switch in the

“AUTO” position, the T.Q.C. will automatically keep the

mix in the freezing cylinder at the proper viscosity and

ready for serving.

The Models 150 and 152 are available with the T.Q.C.

as an option.

Indicator Light -- “ Mix Low”

A mix level indicating light is located at the front of the

machine. When the light is on, it indicates that the mix

hopper has a l ow supply o f mix and should be refilled

as soon as possible. Always maintain at least 2” (5.1

cm) of mix in the hopper. If you neglect to add mix, a

freeze-up may occur. This will cause eventual damage

to the beater assembly and to the freezer door.