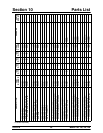

25

Models 150, 152, 162, 168 Troubleshooting Guide

PROBLEM PROBABLE CAUSE REMEDY PAGE

REF.

4. The product is too soft. a. The temperature control

or the T.Q.C. is set too

warm.

a. Adjust the temperature

control. If T.Q.C., contact

service technician.

11

b. The air tube is not

installed.

b. Install the air tube in the

mix inlet hole at the

bottom of the mix hopper.

19

c. Out-drawing the freezer’s

capacity.

c. Two 4 oz. (113.4 gram)

servings in one minute.

---

5. The freezing cylinder walls

are scored.

a. Operating freezer without

the front bearing on the

freezer door.

a. Install the front bearing on

the freezer door.

14

b. The gear unit or the direct

drive is out of alignment.

b. Contact service

technician.

---

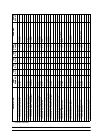

6. Excessive leakage in rear

drip pan.

a. A worn or defective o-ring

is on the beater dr ive

shaft.

a. Replace o -rings every 3

months.

27

b. The rear s hell bearing is

worn.

b. Contact service

technician.

---

c. Incorrect lubricant was

used.

c. Use food grade lubricant

(example: Taylor Lube).

14

d. Inadequate lubrication o f

beater drive shaft.

d. Lubricate the beater drive

shaft properly.

14

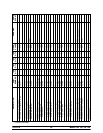

7. The draw valve is leaking. a. Incorrect lubricant was

used.

a. Use food grade lubricant

(example: Taylor Lube).

15

b. Worn or defective o-rings

are on the draw valve.

b. Replace o -rings every 3

months.

27

c. Inadequate l ubrication of

draw valve.

c. Lubricate the draw valve

properly.

15

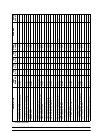

8. Product is not feeding into

the freezing cylinder .

a. The mix lev el is

inadequate in the mix

hopper.

a. Fill the mix hopper with

mix.

19

b. The mix inlet hole is

frozen.

b. Contact service

technician.

11