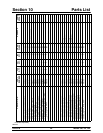

22

Models 340, 341, 342Troubleshooting Guide

Section 8 Troubleshooting Guide

PROBLEM PROBABLE CAUSE REMEDY PAGE

REF.

1. No product i s being

dispensed with the draw

valve opened.

a. Improper mixing of

product.

a. Carefully follow the

directions for mixing the

product.

-- --

b. There is a mix low

condition.

b. Add mix to the mix

hopper.

9

c. The torque arm i s not

installed.

c. Install the torque arm.

d. The torque rotor is bent or

improperly installed.

d. Replace the bent rotor or

follow the assembly

procedures.

11

2. The product is too thin. a. Improper mixing of

product.

a. Carefully follow the

directions for mixing

product.

-- --

b. Scraper blades are

missing or incorrectly

installed.

b. Replace or install the

scraper blades correctly.

10

c. The consistency control

knob needs adjusting.

c. Adjust accordingly. 9

d. The torque rotor bound,

leaving the torque arm in

the “COLD” position.

Therefore, the compressor

will not run. (Far Right)

d. Free the torque rotor . -- --

3. The product is too stiff. a. The torque rotor bound,

leaving the torque arm in

the “WARM” position.

Therefore, the compressor

continually runs. (Far Left)

a. Free the torque rotor . -- --

b. The torque arm i s bent or

is missing.

b. Install o r replace the

torque arm.

13

c. The consistency control

knob needs adjusting.

c. Adjust accordingly. 9

d. Improper mixing of

product.

d. Carefully follow the

directions for mixing

product.

-- --

e. There is insufficient

product in the freezing

cylinder.

e. Keep the hopper full of

mix.

9