Food Preparation and Storage Guide

THE FOODSAVER USER MANUAL

23

THE FOODSAVER USER MANUAL

22

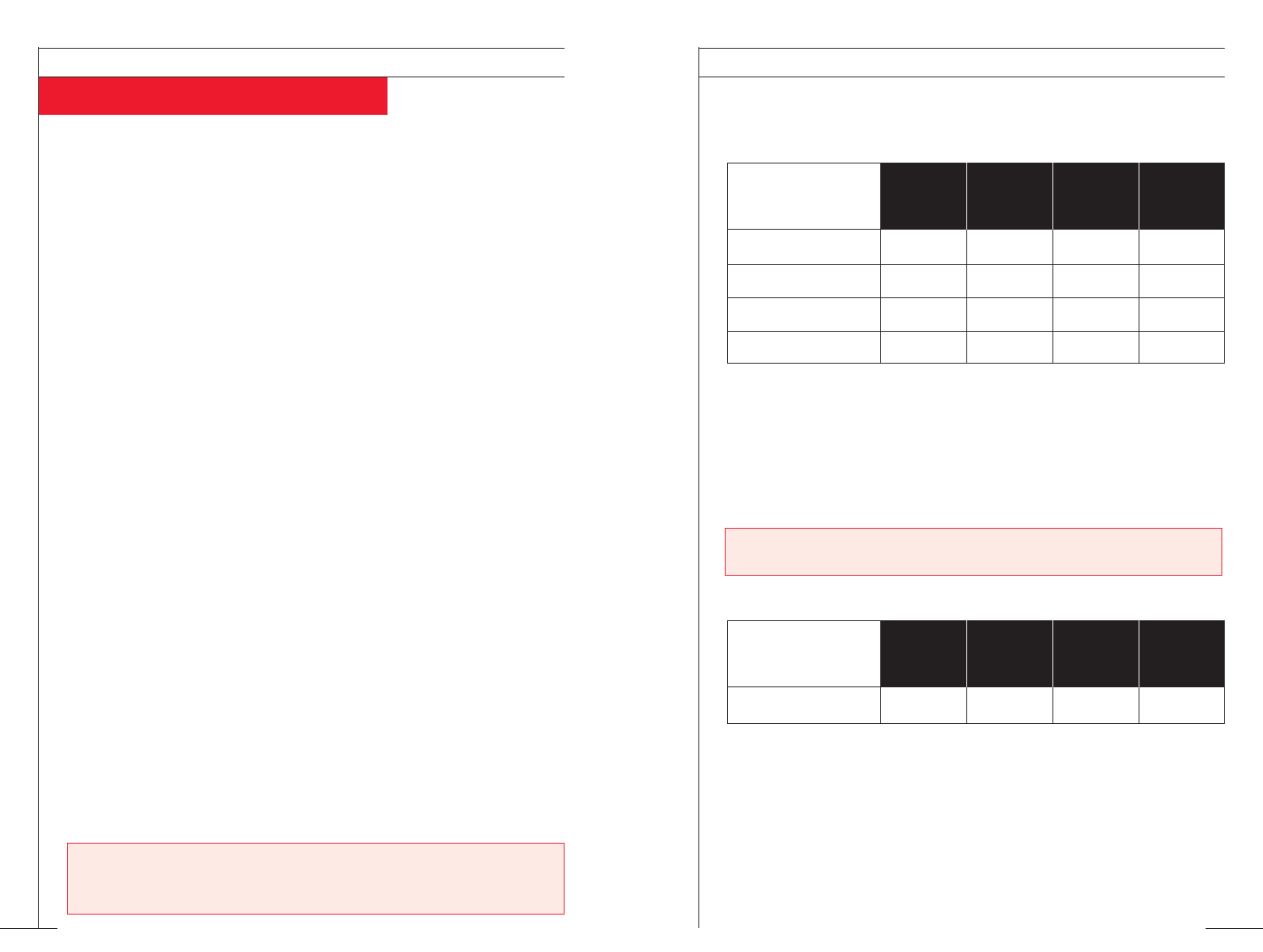

Where to Recommended Vacuum Normal Storage

MEATS

/FISH Store FoodSaver Packaged Life

(without

Container Storage Life

vacuum packaging)

Beef, Lamb, Pork

Freezer FoodSaver Bag 2 to 3 years 6 months

Ground meat Freezer FoodSaver Bag 1 year 4 months

Poultry Freezer FoodSaver Bag 2 to 3 years 6 months

Fish Freezer FoodSaver Bag 2 years 6 months

Where to Recommended Vacuum Normal Storage

C

HEESES Store FoodSaver Packaged Life

(without

Container Storage Life

vacuum packaging)

Cheddar, Swiss, Parmesan Refrigerator FoodSaver Bag 4 to 8 months 1 to 2 weeks

Preparation Guidelines for Meats/Fish:

Option 1: For best results pre-freeze

meats and fish for 1-2 hours before

vacuum packaging in a FoodSaver

Bag to ensure the retention of juices

and shape, and to help guarantee a

good seal.

Option 2: If it is not possible to pre-

freeze, place a folded paper towel

between the meat/fish and the end

of the bag. Leave the paper towel in

the bag when vacuum packaging to

absorb excess moisture and juices.

Preparation Guidelines for Hard Cheeses:

Keep cheese fresh even if you use

it everyday by vacuum packaging it

after each use. Make your original

FoodSaver Bag extra long. Simply

cut along the sealed edge, remove

the cheese and slice off the amount

needed, then place the cheese back

in the bag and repackage. Allow

approximately one inch of bag

material for each time the bag will

be opened and repackaged.

NOTE: Beef may appear darker after vacuum packaging due to the removal

of oxygen. This is not an indication of spoilage.

Guidelines for Vacuum

Packaging Food

Vacuum packaging is not a substitute

for canning nor can it reverse deteri-

orating quality; it can only slow down

changes in quality. It is impossible to

predict how long a specific food will

have top-quality flavor, appearance

and texture, because it depends on

the age and condition of the food

on the day it was vacuum packaged.

Any perishable foods that require

refrigeration still must be refriger

ated

or frozen after vacuum packaging.

Vacuum packaging extends the life of

foods by removing nearly all the air in

a sealed container, thereby reducing

oxidation which affects nutritional

value, flavor and overall quality.

However, most foods contain enough

water to support micro-organisms

which can grow with or without air.

While micro-organisms are present

everywhere, only certain ones cause

problems, and only under certain

conditions:

◗ Mold: Easy to identify because of

its characteristic fuzz. Molds are

virtually eliminated by vacuum

packaging because they cannot

grow in a low oxygen environment.

◗ Yeast: Results in fermentation,

which can frequently be identified by

smell or taste. Yeast requires water,

sugar and a moderate temperature

to grow, but can grow with or

without air. Refrigeration slows

the growth of yeast, and freezing

stops it completely.

◗ Bacteria: Frequently results in

discoloration, soft or slimy texture

and/or an unpleasant odor. Clostrid-

ium botulinum (the organism that

causes Botulism) can grow without

air under the right conditions,

cannot be detected by smell or

taste and, although extremely rare,

can be very dangerous.

Maintaining low temperatures is a

critical factor in preserving foods

safely. Growth of micro-organisms is

significantly reduced at temperatures

of 40°F (4°C) or below. Freezing at

0°F (-17°C) does not kill micro-

organisms, but stops them from

growing. For long-term storage, always

freeze “perishable” foods that have

been vacuum packaged.

Thawing and Heating Vacuum

Packaged Foods

Always thaw foods in either the

refrigerator or microwave – do not

leave “perishable” foods at room

temperature to thaw.

To microwave in a FoodSaver Bag,

cut a corner of the bag and place on

a microwave-safe dish. You can also

place the FoodSaver Bag in boiling

water to heat.

NOTE: Vacuum packaging is NOT a substitute for refrigeration or freezing.

Any “perishable” foods that require refrigeration prior to vacuum packaging

still must be refrigerated or frozen after vacuum packaging.