10

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Also see Figure 14.

6 1/2"

(152 mm)

3"

(76 mm)

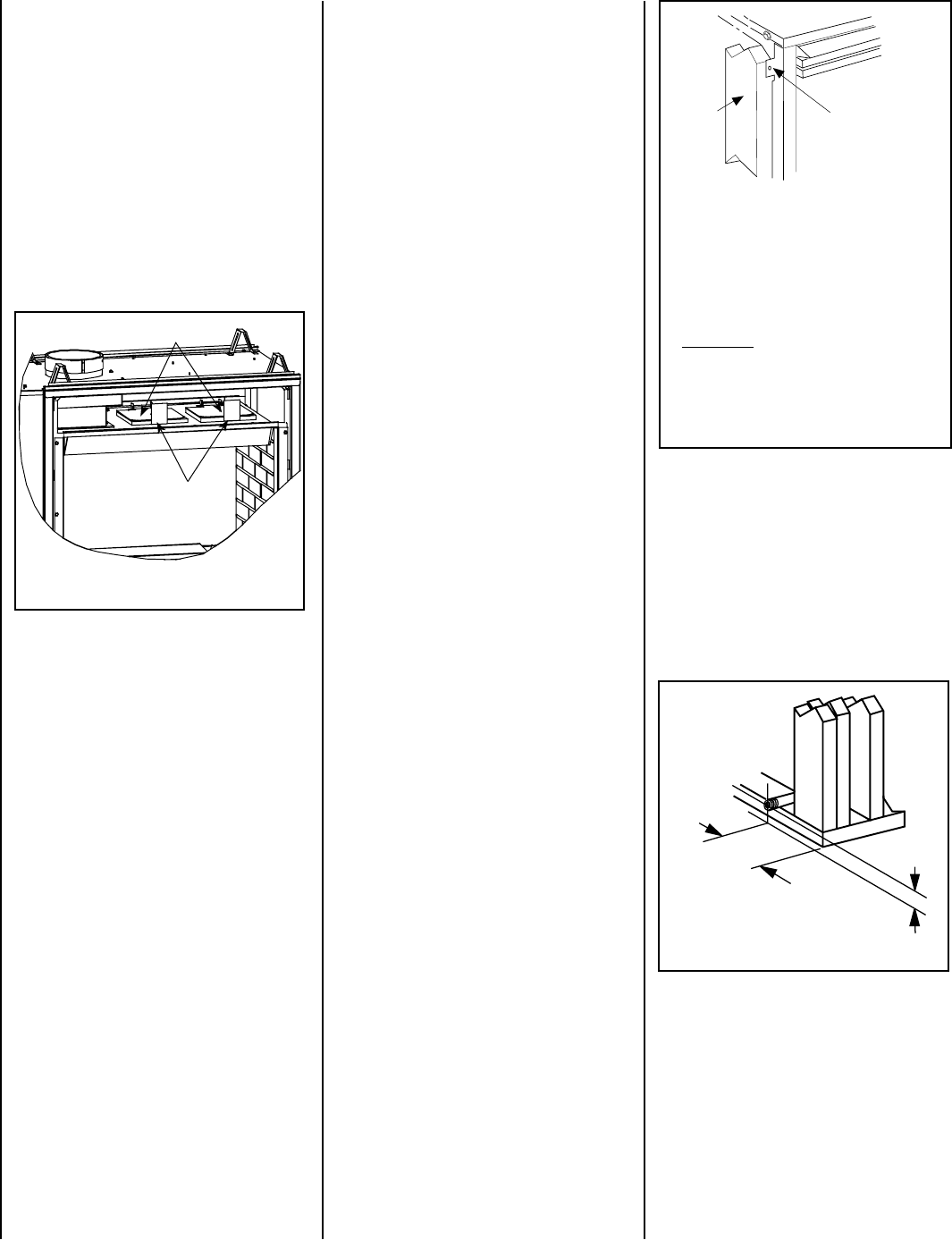

Figure 13 - ROUTE GAS LINE

Right Side Front

Corner of Fire-

place Framing

Continued on Page 12.

TYPICAL INSTALLATION SEQUENCE

The typical sequence of installation follows,

however, each installation is unique resulting

in variations to those described.

See the Page numbers references in the follow-

ing steps for detailed procedures.

Step 1. (Page 10) Construct the appliance

framing. Position the appliance within the

framing and secure with nailing brackets.

Step 2. (Page 10) Route gas supply line to

appliance location.

Step 3. (Page 13) Install the vent system and

exterior termination.

Figure 11

REMOVE

CARDBOARD

BEFORE USING

REMOVE

CARDBOARD

BEFORE USING

Pressure Relief Plates

Remove Cardboard Before

Using Appliance

STEP 2. ROUTING GAS LINE

Route a 1/2" (13 mm) gas line along the inside

of the right side framing as shown in Tables.

Gas lines must be routed, constructed and made

of materials that are in strict accordance with

local codes and regulations. All appliances are

factory-equipped with a flexible gas line con-

nector and 1/2 inch shutoff valve. (See Step 6

on Page 26).

DETAILED INSTALLATION STEPS

The appliance is shipped with all gas controls

and components installed and pre-wired. Re-

move the shipping carton, exposing the front

glass door. Remove the top and bottom louvered

control panel per instructions on Page 27 (see

Control Compartment Access / Louver Panel

Instructions). Remove the cardboard from

underneath the pressure relief plates, in area

behind top louver panel (see Figure 11). Open

the two latches (located under the firebox floor)

securing the glass door. Remove the door by

tilting it outward at the bottom and lifting it up.

Set the door aside protecting it from inadvertent

damage. See Figure 54 on Page 30.

Step 4. (Page 25) Field Wiring

a. Millivolt Appliances – Install the operating

control switch (not factory provided) and

bring in electrical service line for forced air

circulating blower (optional equipment).

b. Electronic Appliances – Field wire and install

operating control switch.

Step 5. (Page 25) Install blower kit (optional

equipment).

Step 6. (Page 26) Make connection to gas sup-

ply.

Step 7. (Page 27) Checkout appliance operation.

Step 8. (Page 28) Install the logs, decorative

volcanic stone and glowing embers.

Step 9. (Page 30) Install glass door frame as-

sembly.

Step 10. (Page 30) Adjust burner to ensure proper

flame appearance.

Step 11. (Page 31) Install the hoods.

Step 1. FRAMING

Frame these appliances as illustrated in Figure

14 on Page 11, unless the appliance is to be

installed in a corner. See Figure 15 on Page

12 for corner framing installations. All framing

details must allow for a minimum clearance to

combustible framing members as shown in

Table 8 on Page 9.

If the appliance is to be elevated above floor

level, a solid continuous platform must be

constructed.

Headers may be in direct contact with the

appliance top spacers but must not be sup-

ported by them or notched to fit around them.

All construction above the appliance must be

self supporting. DO NOT use the appliance for

structural support.

The fireplace should be secured to the side framing

members using the unit's nailing flanges - one top

and bottom on each side of the fireplace front. See

Figure 12. Use 8d nails or their equivalent.

Figure 12

Note: The nailing flanges, combustible members

and screw heads located in areas directly adjacent

to the nailing flanges, are EXEMPT from the 1/2”

clearance to combustible requirements for the

firebox outer wrapper

. Combustible framing may be

in

direct contact with the nailing flanges and may

be located closer than 1/2” from screw heads and

the firebox wrapper in areas adjacent to the nailing

flanges. Frame the opening to the exact dimensions

specified in the framing details of this manual.

Side

Framing

Unit Nailing Flange

(No clearance to

combustible

framing is required)

Left Side Front Corner of Fireplace Shown

(Right Side Requirements the Same)

Unit Being Secured By Its Nailing Flanges

To The Framing