12

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

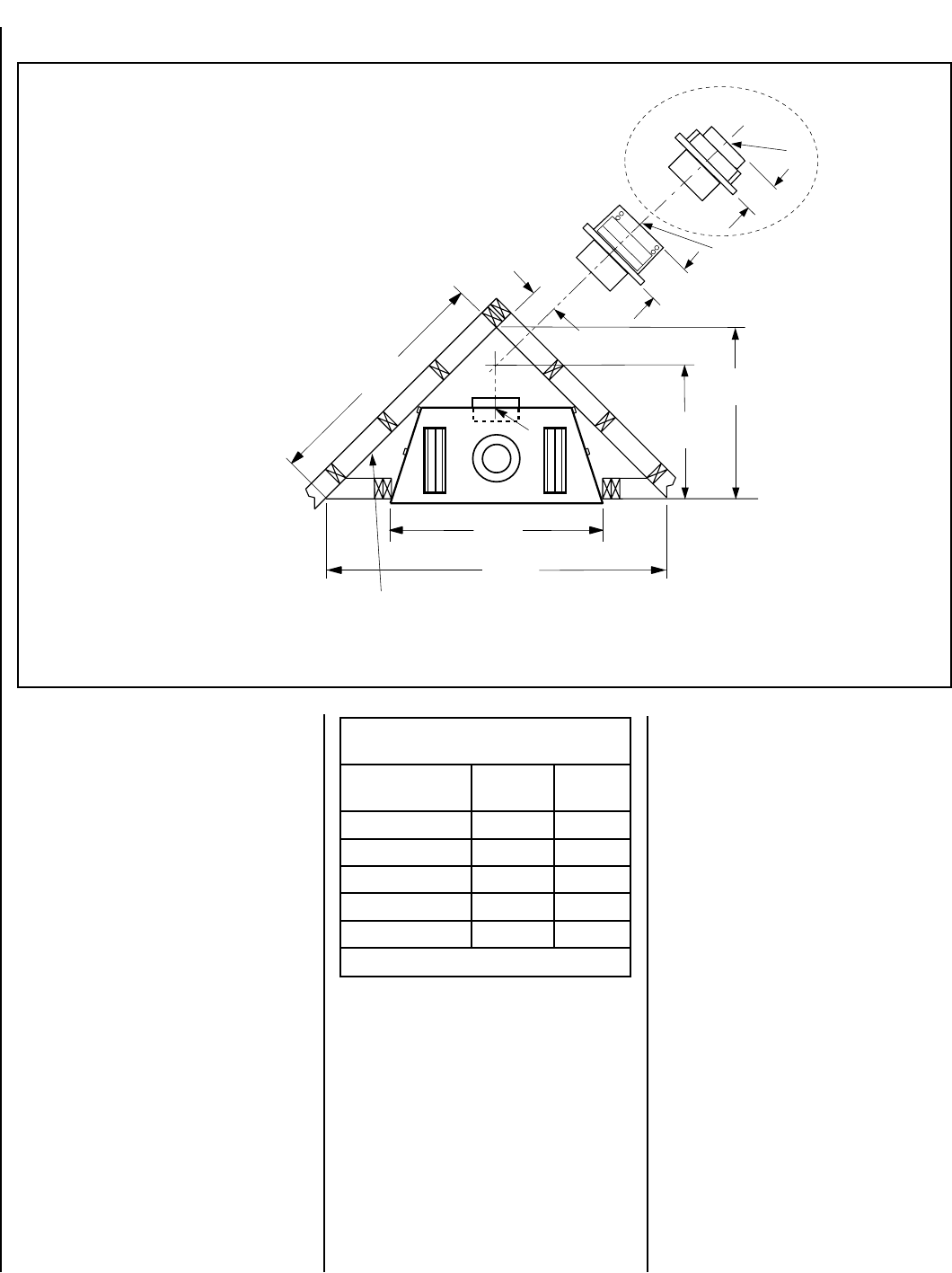

Figure 15

Corner Framing with Square Termination (SV4.5HT-2)

Schedule 40 / Black Iron Pipe

Inside Diameter (Inches)

Schedule 40 Pipe

Length (feet)

Natural

Gas

Propane

Gas

0-10 1/2 3/8

10-40 1/2 1/2

40-100 1/2 1/2

100-150 3/4 1/2

150-200 3/4 1/2

Table 9

• A pipe joint compound rated for gas should be

used on the threaded joints. Ensure propane

resistant compounds are used in propane

applications. Be very careful that the pipe

compound does not get inside the pipe.

• It is recommended to install a sediment trap

in the supply line as close as possible to the

appliance (see Figure 46). Appliances using

Propane should have a sediment trap at the

base of the tank.

• Check with local building official for local code

requirements (i.e. are below grade penetrations

of the gas line allowed, etc).

IMPORTANT: If propane is used, be aware that

if tank size is too small (i.e. under 100-lbs, if

this is the only gas appliance in the dwelling.

Ref. NPFA 58), there may be loss of pressure,

resulting in insufficient fuel delivery (which

can result in sooting, severe delayed ignition

or other malfunctions). Any damage resulting

from an improper installation, such as this, is

not covered under the limited warranty.

Proper Sizing of Gas Line

Properly size and route the gas supply line

from the supply regulator to the area where

the appliance is to be installed per require-

ments outlined in the National Fuel Gas Code,

NFPA 54 - latest edition (USA) or B149 - latest

edition (Canada).

Never use galvanized or plastic pipe. Refer to

Table 9 for proper sizing of the gas supply line,

if black iron pipe is being used. Gas lines must

be routed, constructed and made of materials

that are in strict accordance with local codes

and regulations. We recommend that a quali-

fied individual such as a plumber or gas fitter

be hired to correctly size and route the gas

supply line to the appliance. Installing a gas

supply line from the fuel supply to the appliance

involves numerous considerations of materials,

protection, sizing, locations, controls, pressure,

sediment, and more. Certainly no one unfamiliar

and unqualified should attempt sizing or install-

ing gas piping.

Notes:

• All appliances are factory-equipped with a

flexible gas line connector and 1/2 inch shutoff

valve (see Figure 46 on Page 26 ).

• See

Massachusetts Requirements on Page

4 for additional requirements for installations

in the state of Massachusetts in the USA.

• The gas supply line should Not be connected

to the appliance until Step 6 (Page 26).

*34-5/16

(872)

Back wall of chase/enclosure (including any finishing materials)

a

8-3/16 (208)

b

Note-

Venting requirements for rear vent applications in corner installations -

- the horizontal vent length a to b, must not exceed 28 inches (711 mm)

*17-3/16

(437)

Inches

(millimeters)

*These dimensions occur when one 45

degree elbow is connected directly to the

appliance collar and the unit moved 1/2

in. (13 mm) into the room. This 1/2 in.

movement is required to achieve a min.

of 5 in (127 mm) in the F dimension.

*F = 5 in.

(127 mm)

*24-1/4

(616)

33-1/8

(841)

*48-1/2

(1232)

SV4.5HTSS & SV4.5HTSSL

Termination

Framing should be constructed of

2x4 or larger lumber.

7 (178)

b

SV4.5HT-2 Termination

FIREPLACE FRAMING SPECIFICATIONS