19

Horizontal / Inclined Run

Support Brackets

Building

Support

Framing

SV4.5E90

Elbow

Ceiling

Firestop / Spacer

SV4.5VF

When Using Secure Flex,

Use Firestop / Spacer SF4.5VF

Fireplace

SV4.5L6/12/24/36/48

Vent Sections

Vertical

Rise

SV4.5HT-2

Termination

Shown

Support Bracket Spacing

Every 5 ft (1.52 m)

Exterior

Wall

SV4.5HT-2

Termination

Shown

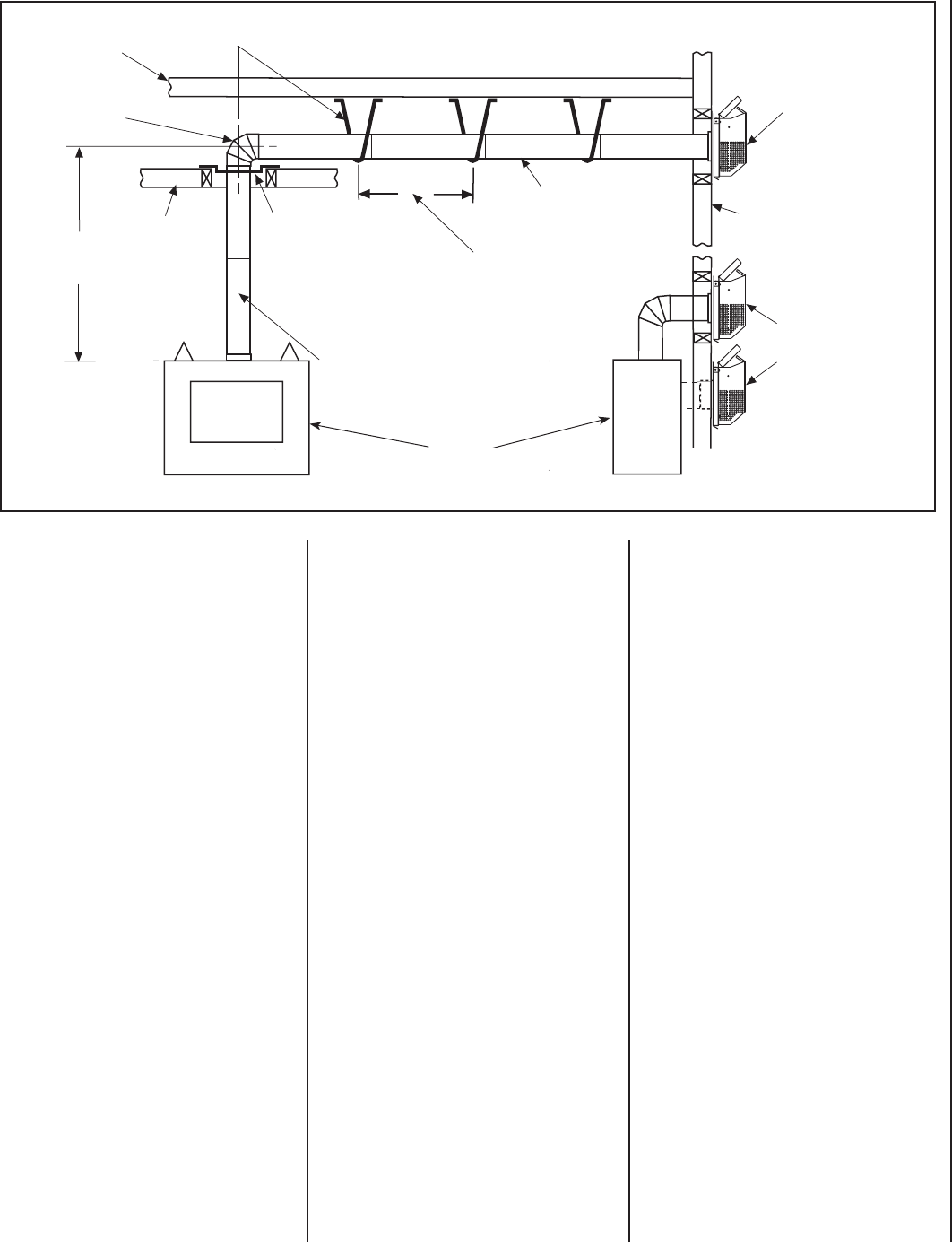

Figure 31 - TYPICAL HORIZONTAL VENT INSTALLATION

See Figure 18 on Page 14 or Figure 21 on

Page 15 for vertical vent section support.

B. Frame exterior wall opening -

Locate the center of the vent outlet on

the exterior wall according to the dimen-

sions shown in Figure 14 on Page 11. Cut

and/or frame an opening, 10-1/2" x 12-1/8"

(267 mm x 308mm) inside dimensions, about

this center.

C. Frame ceiling opening - If the vertical route

is to penetrate a ceiling, use plumb line to locate

the center above the appliance. Cut and/or frame

an opening, 10-1/2" x 10-1/2" (267 mm x 267

mm) inside dimensions, about this center (refer

to Figure 19 on Page 15).

D. Attach vent components to appliance - To

attach a vent component to the appliance collar,

align the dimpled end over the collar, adjust-

ing the radial alignment until the four locking

dimples are aligned with the inlets of the four

incline channels on the collar (refer to Figure

20 on Page 15).

Push the vent component against the collar

until it fully engages, then twist the component

clockwise, running the dimples down and along

the incline channels until they seat at the end

of the channels.

The unitized design of the Secure Vent

components will engage and seal both the

inner and outer pipe elements with the same

procedure. Sealant and securing screws are

not required.

Note: An elbow may also be attached to the

appliance collar. Attach in the same manner

as you would a vent section.

E. Attach vent components to each other

- Other vent sections may be added to the pre-

viously installed section in accordance with the

requirements of the vent tables. To add another

vent component to a length of vent run, align the

dimpled end of the component over the inclined

channel end of the previously installed section,

adjusting the radial alignment until the four lock-

ing dimples are aligned with the inlets of the four

incline channels of the previous section.

Push the vent component against the previous

section until it fully engages, then twist the

component clockwise running the dimples down

and along the incline channels until they seat at

the end of the channels.This seating position

is indicated by the alignment of the arrow and

dimple as shown in Figure 20 on Page 15.

F. Install fi restop/spacer at ceiling -

When using Secure Vent, use SV4.5VF fi restop/

spacer at ceiling joists; when using Secure Flex,

use SF4.5VF fi restop/spacer.

If there is living space above the ceiling level,

the fi restop/ spacer must be installed on the

bottom side of the ceiling. If attic space is

above the ceiling, the fi restop/ spacer must be

installed on the top side of the joist. Route the

vent sections through the framed opening and

secure the fi restop/spacer with 8d nails or other

appropriate fasteners at each corner.

Remember to maintain 1" (25 mm) clearance

to combustibles, framing members, and attic

or ceiling insulation when running vertical

chimney sections.

G. Support the vertical run sections -

See Section E on Page 15.

H. Change vent direction - At transition from or

to a horizontal/inclined run, install the SV4.5E45

and SV4.5E90 elbows in the same manner as

the straight vent sections. The elbows feature a

twist section to allow them to be routed about the

center axis of their initial collar section to align

with the required direction of the next vent run

element. Twist elbow sections in a clockwise

direction only so as to avoid the possiblity of

unlocking any of the previously connected vent

sections. See Figure 22 on Page 16.

I. Continue installation of horizontal/inclined

sections - Continue with the installation of the

straight vent sections in horizontal/inclined run

as described in Step E. Install support straps

every 5 ft. (1.52 m) along horizontal/inclined

vent runs using conventional plumber’s tape.

See Figure 31. It is very important that the

horizontal/inclined run be maintained in a

straight (no dips) and recommended to be in

a slightly elevated plane, in a direction away

from the fi replace of 1/4" rise per foot (20 mm

per meter) which is ideal, though rise per foot

run ratios that are smaller are acceptable all the

way down to at or near level.

It is important to maintain the required clear-

ances to combustibles: 1" (25 mm) at all sides

for all vertical runs; and 3" (76 mm) at the top,

1" (25 mm) at sides, and 1" (25 mm) at the

bottom for all horizontal/inclined runs.