NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

26

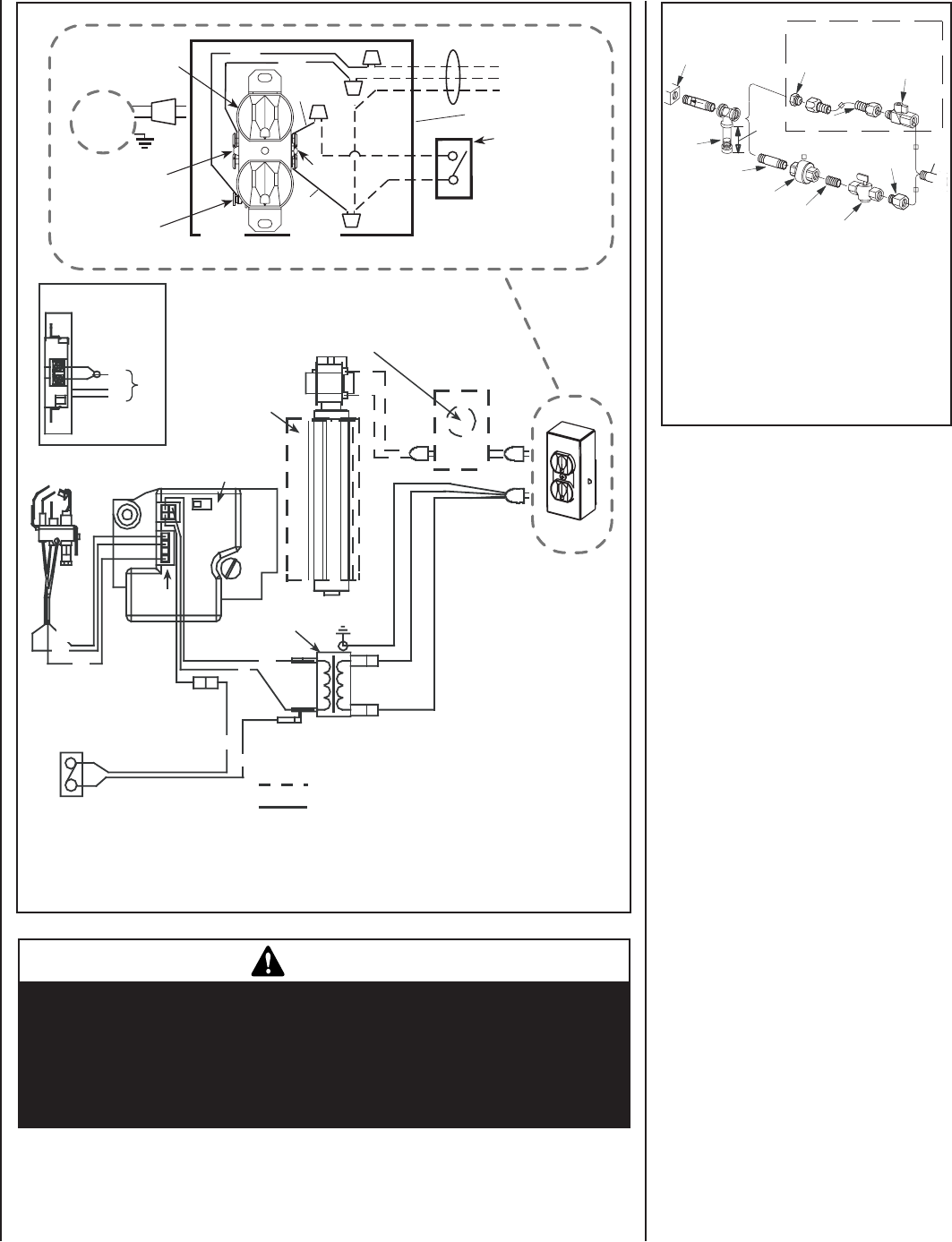

Electronic Wiring Diagram (Honeywell) Showing Blower Wiring for Optional FBK-100, FBK-200 & FBK-250 Kits

Schematic Representation Only

Relay Module C/W FBK-250 only. Plug blower

into J-Box receptacle for FBK-100 or FBK-200

application. See View A for J-Box wiring.

Optional Blower

*OFF/ON Switch

(Integral with

Gas Valve)

Honeywell

Electronic

Gas

Valve

120 VAC

Primary

Secondary

Optional Control Switch

Junction Box

Pilot Burner

Assembly

BL

BL

Field Wired

Factory

Wired

BK = BLACK BL = BLUE

R = RED W = WHITE

G = GREEN

BK

W

BK

BK

BL

R

GROUND

24 V

Transformer

View A

J-Box Wiring when

using unit mounted

relay module.

BK

W

G

CAV 021

Igniter

Connector

* Leave the OFF/ON switch, which is

integral with the gas valve, in the ON

position.

**Optional Control Switches: Wall

Switch, Wall Thermostat or Remote

Control Receiver.

Notes:

1. If any of the original wire as supplied

must be replaced, use Type AWM 105°C

- 18 gage wire ONLY.

2. 120 VAC, 60 Hz - Less than 3 Amps.

Caution: label all wires prior to

disconnection when servicing controls.

Wiring errors can cause improper and

dangerous operation.

Junction Box

Tab Intact

Tab

Broken

Plug blower

into this

receptacle

n

e

e

r

G

-

dn

u

o

r

G

* Wall-mounted

ON/ OFF Blower

Switch or Variable

Speed Control Switch.

Blower

Ground

e

ti

h

W

-

lar

t

u

e

N

120 VAC - Black

Green

Ground

Screw

White

Green

Neutral

Side of

Receptacle

Hot

Side of

Receptacle

Red

Black

J-BOX WIRING FOR

WALL SWITCH

BLOWER CONTROL

Figure 45

CAUTION

Ground supply lead must be connected to the wire attached to the green

ground screw located on the outlet box. See Figure 47. Failure to do so

will result in a potential safety hazard. The appliance must be electrically

grounded in accordance with local codes or, in the absence of local codes,

the National Electrical Code, ANSI/NFPA 70-latest edition. (In Canada, the

current CSA C22-1 Canadian Electrical Code).

Step 6. CONNECTING GAS LINE

Make gas line connections. All codes require a

shut-off valve mounted in the supply line. Figure

46 illustrates two methods for connecting the

gas supply. The fl ex-line method is acceptable

in the U.S., however, Canadian requirements

vary depending on locality. Installation must

be in compliance with local codes.

These appliances are equipped with a gas fl ex

line for use (where permitted) in connecting

the appliance to the gas line. A gas fl ex line

is provided to aid in attaching the direct vent

appliance to the gas supply. The gas fl ex line

can only be used where local codes permit. See

Figure 46 for fl ex line description. The fl ex line

is rated for both natural gas and propane gas.

A manual shut off valve is also provided with

the fl ex line.

The incoming gas line should be piped into

the valve compartment and connected (see

Figures 46 & 47). The millivolt control

valve has a 3/8" (10 mm) NPT thread

inlet port. The electronic control valve

has a 1/2" (13 mm) NPT thread inlet port

and is fi tted with a 1/2" x 3/8" (13 mm x

10 mm) NPT fi tting.

Secure all joints tightly using appropriate

tools and sealing compounds (ensure propane

resistant compounds are used in propane

applications).

Optional: Seal around the gas line to prevent

cold air leakage.

Note:The gas supply line must be installed in accor-

dance with building codes by a qualifi ed installer

approved and/or licensed as requed by the locality.

In the Commonwealth of Massachusetts, installa-

tion must be performed by a licensed plumber or

gas fi tter.

Gas

Valve

3/8" NPT x

Flare Fitting

3/8" Flex Tubing

3/8" Nipple

3/8" Union

3/8" Close Nipple

3/8" Shut-off Valve

1/2" x 3/8"

Reducer

Gas

Stub

1/2" x 3/8" Flare

Shut-off Valve

Gas Flex Line Connector

*Sediment

Trap

3"

Min

*A Sediment Trap is recommended to prevent moisture

and debris in gas line from damaging the valve.

Figure 46 - GAS CONNECTION