VII. c - COMPONENT FUNCTION:

VII. ELECTRICAL OPERATION

-15-

VII. d - INSTALLATION OF THE SENSORS:

Compressor: Pumps refrigerant thru refrigeration system components and

compresses the low pressure vapor into high pressure vapor.

Condenser Fan: Draws air across condenser coil to aid in removing heat from the

refrigerant andmoves air across compressor to aid in cooling the

compressor.

Evaporator Fan: Draws air from the cabinet and pulls the air thru the evaporator coil.

Start Capacitor: Stores electrical charge which helps start the compressor motor.

Run Capacitor: Helps keep the compressor motor running after starting.

Microprocessor Control: Performs the functions of the 1) defrost timer, 2) high limit switch,

3) thermometer and 4) thermostat.

Drawer Perimeter Heater: Heats drawer opening to prevent condensation from forming.

Contactor Relay: Controls voltage to compressor motors.

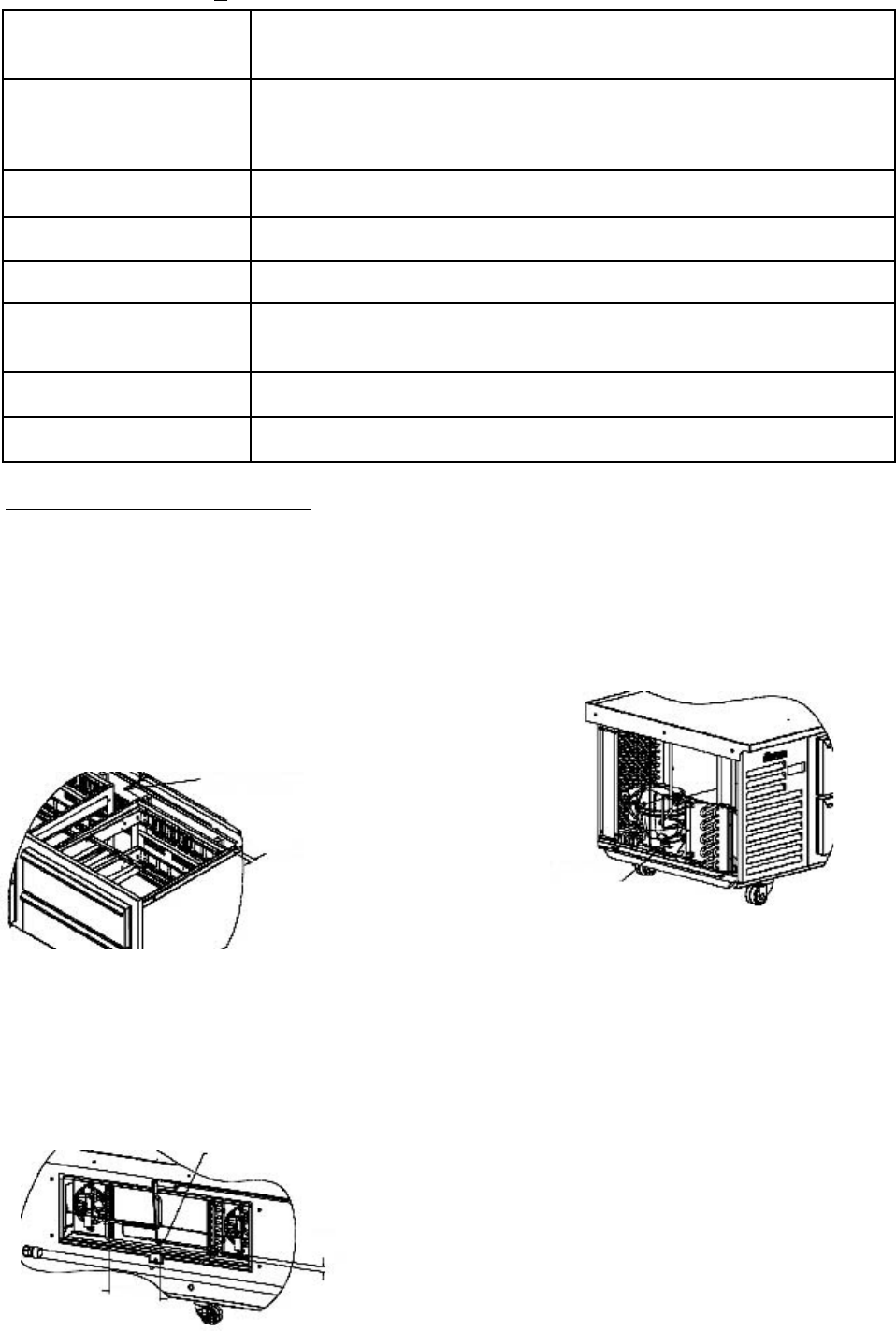

There are two sensors used inside the

cabinet. The first one is the Cabinet Sensor

that is used to cycle the compressor on and

off at the correct temperature. The cabinet

sensor is mounted between the two coils

just below the top of the cabinet thru the

1/2” holes in the back wall and the tip should

be 1” inside the cabinet. Refer to the

drawing below. The part number for the

Cabinet Sensor is 337-60405-03.

The third sensor used is a Liquid Line

Sensor. This sensor is to be installed on

the liquid line as it comes out of the

condenser coil. The part number for this

sensor is 337-60407-01.

The Evaporator Coil Sensor is to be mounted

in the evaporator, in the center of the coil

and fully inserted into the coil until only the

wire is visible and then pinch the fins around

the cable to hold it in place. The part

number for the Evaporator Coil Sensor is

337-60406-03.

When the condensing temperature reaches

140°F or greater the control will display

“CLN-FIL.” Should the condensing

temperature increase to 160°F the

compressor will automatically shut off.

When the liquid line temperature drops

below 140°F the compressor will restart and

when the line temperature drops to 120°F

the alarm will reset.

Attach sensor to the

liquid line using the

wrap

Center

of Coil

Fully insert probe

into coil

Insert sensor inside the cabinet thru

1/2” holes in back wall

1” inside cabinet

.756 between 1

st

and 2

nd

hair bend