II. a - INTRODUCTION:

This manual applies to the following Traulsen

models only:

TE036HT, TE048HT, TE060HT, TE065HT, TE072HT

TE084HT, TE096HT, TE110HT, TE125HT &

TE139HT

II. b - MODEL DESIGNATIONS:

Position 1: TE = Traulsen Equipment Stand

Position 2: 036 = 36” Long Model

048 = 48” Long Model

060 = 60” Long Model

Position 3: HT = Refrigerator

II. c - WIRING DIAGRAM:

Refer to the wiring diagram for any service work

performed on this unit. A copy is located on the unit

when shipped. Should you require another copy, or a

wiring diagram for an older production unit, please

contact Traulsen Service at (800) 825-8220, and

provide the model and serial number of the unit

involved (this information is located on the serial

tag, see page one).

II. d - INSTALLATION:

Generally TE-Series refrigeration products are installed

by the dealer, or others contracted by the dealer or

owner. Detailed installation instructions are included

along with each unit when shipped.

II. e - CLEANING:

Detailed cleaning instructions are included with each

unit, however special care MUST be given to the

condenser coil. The condenser coil must be cleaned

at a minimum of every six months. This can be done

with a vacuum cleaner using a brush attachment, or a

stiff brush or wisk broom. For more information please

refer to

“Section V.a” of the TE-Series Owner’s

Manual.

II. f - TOOL REQUIREMENTS:

For most jobs a standard set of hand tools, a VOM and

AC current tester, along with a temperature tester or

thermometer are adequate. However in some cases

the following additional tools may be required as well:

• Refrigeration Guage Manifold

• Refrigeration Reclaiming Equipment

• Acetylene Torch

• Anti-Static Grounding Kit (TL 84919)

• Nitrogen Bottle With Gauges

• Thin 5/16” Open End Wrench

• Refrigerant Reclaim Unit

II. GENERAL INFORMATION

-2-

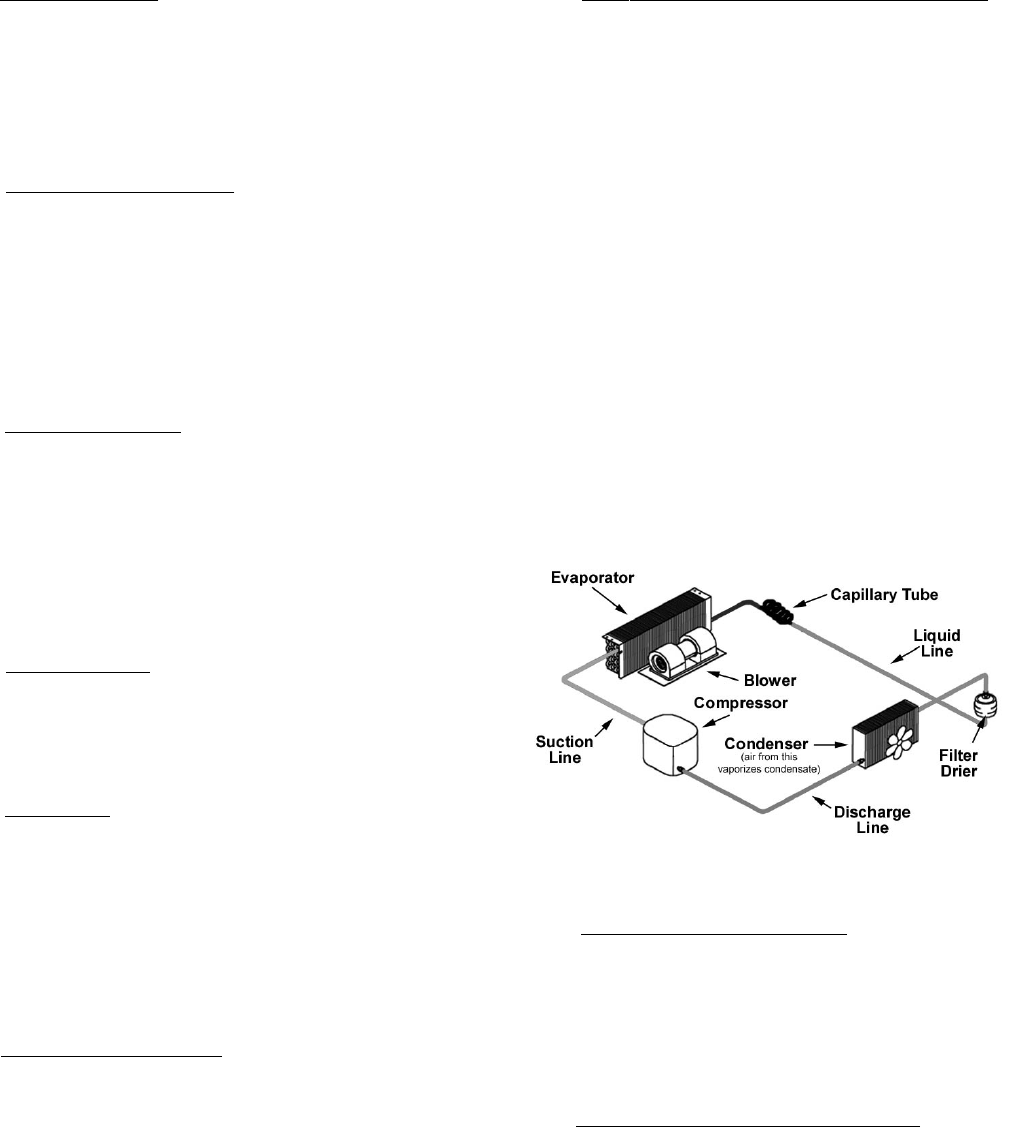

II. g - REF’N SYSTEM - THEORY OF OPERATION:

The refrigeration system is the mechanism whereby

heat is transferred from the cabinet to the outside air.

It works under the principle that the heat moves from

hot to cold as it tries to establish equilibrium.

The microprocessor control signals a need for heat to

be removed from the cabinet. The compressor begins

by compressing the refrigerant gas as it is discharged.

The high pressure refrigerant now circulates through

the condenser, removing heat from the refrigerant and

condensing it into a liquid. From there the refrigerant

flows to the filter drier which removes all traces of

moisture and particles from the system.

After the filter drier, the refrigerant passes through a

“metering device.” Traulsen uses a capillary tube to

regulate the flow of refrigerant into the evaporator

coils.

In the evaporator coil, heat is transferred from the

cabinet to the refrigerant, which changes from a cold

liquid to a warm low pressure gas. When the desired

cabinet air temperature has been reached, the

microprocessor control shuts off the compressor.

II. h - AIR FLOW REQUIREMENTS:

To assure optimum performance, the condensing unit

of your Traulsen unit MUST have an adequate supply

of air for cooling purposes. Therefore, the operating

location must allow a minimum of 12” clearance in

front of the louvers to allow for unrestricted air flow to

the condensing unit.

II. i - THE MICROPROCESSOR CONTROL:

For detailed information on replacement, repair or

adjustment of the INTELA-TRAUL

®

microprocessor

control please refer to it’s service manual (form

number TR35705).

Fig. 1 - The Refrigeration System

TE060HT