V. a - ADJUSTING THE TEMPERATURE:

The refrigeration system has been properly charged

and tested at the factory. Plug the unit into the power

outlet to determine if the compressor(s) is running. If

not, check the “ON/OFF” switches behind the louver

assembly. On a refrigerator/freezer models (UR48DT)

there are separate switches for each compartment (lo-

cated on the right side) and both must be in the ON

position.

If, after determining that your Spacesaver unit is func-

tioning, and has had adequate time to pull-down tem-

perature, the temperature is above/below standard

ranges (34 to 38

° F for refrigerators, 0 to -5° F for freez-

ers), adjust the temperature controls. This is a black

knob located behind the louver assembly along the

centerline. It can be adjusted up or down one number

at a time to raise or lower temperature.

V. b - AUTOMATIC DEFROST:

The refrigerator section operates on a “cycle defrost”

basis, which means, at the end of each refrigeration

cycle, the coil is allowed to reach 42° F and defrost

itself. This method allows for maximum efficiency of

the refrigeration system.

The freezer section is normally frost free and never

requires a manual defrost. When the defrost system is

operating, the compressor and fans do not run.

WARNING: DISCONNECT ELECTRICAL POWER

SUPPLY BEFORE CLEANING ANY PARTS OF THE

UNIT.

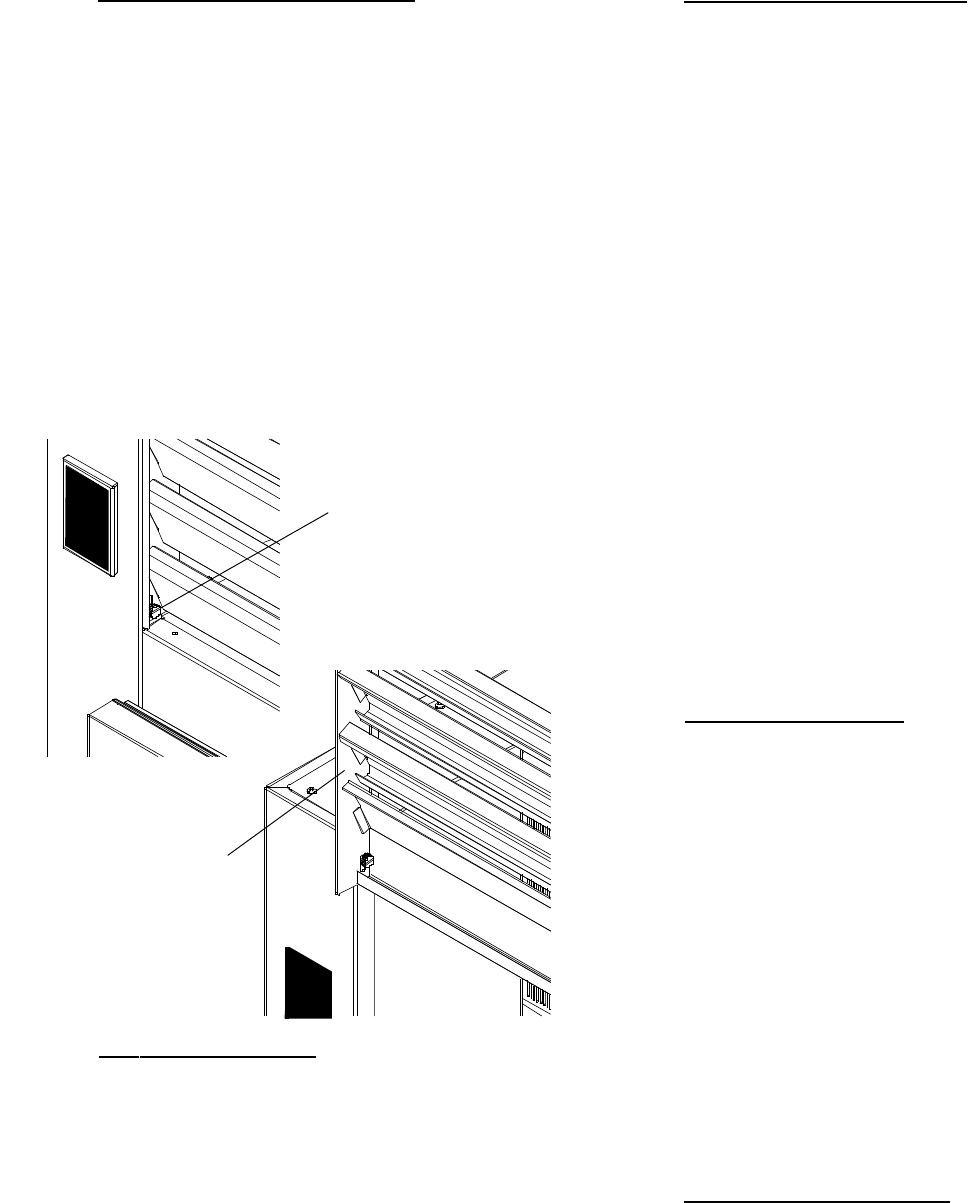

Fig. 8

Lift-Up Louver

Assembly

-6-

V. OPERATION VI. CARE & MAINTENANCE

VI. a - CLEANING THE CONDENSER:

The most important thing you can do to insure a long,

reliable service life for your Traulsen is to regularly

clean the condenser coil.

The condensing unit requires regularly scheduled

cleaning to keep the finned condenser clean of lint

and dust accumulation. The frequency of cleaning

will depend on jobsite conditions, however at least

once a month is strongly recommended. Keeping the

condenser clean allows the cabinet to operate more

efficiently and use less energy.

To clean the condenser, first disconnect electrical

power to the cabinet and lift up the front louver as-

sembly. To lift this, remove the two screws located on

both sides at the bottom of the louver assembly (see

figure 7). Once the screws are removed, the panel

can be pivoted upwards allowing full access to the

front facing condenser (see figure 8). Vacuum or

brush any dirt, lint or dust from the finned condenser

coil, the compressor and other cooling system parts.

If significant dirt is clogging the condenser fins, use

compressed air to blow this clear. Care should be

taken not to bend any of the condenser fins, as this

will reduce performance and compressor life.

Lower louver assembly and replace the screws to hold

it in place.

VI. b - HINGE REPLACEMENT:

Both the door and hinge can be easily removed from

the cabinet. To remove the door, remove the screw at

the bottom of the upper hinge. Inside the upper hinge

there is a small pin screw which secures the door in

place. Remove this with a flat head screwdriver and

the door can then be lifted off the hinge. To remove

the door-half of the hinge from the door, slide hinge

cover downward and then remove the three Phillips

head screws which secure the hinge in place on the

door.

To remove the cabinet-half of the hinge, remove the

three Phillips head screws which hold it in place. On

all units, the top hinge(s) contains a microswitch for

controlling the interior lighting.

To reassemble the hinge reverse the previous proce-

dure.

VI. c - REPLACING THE GASKETS:

To remove the gasket to be replaced, grasp it firmly

by one corner and pull it out. Before attempting to

install a new gasket, both the unit and the gasket it-

self must be at room temperature. Insert the four cor-

ners first by using a rubber mallet (or hammer with a

block of wood). After the corners are properly inserted,

work your way towards the center from both ends by

Fig. 7

Remove

Screws