14

®

CAST IRON STOVE AND BURNER SYSTEM

106707

For more information, visit www.desatech.com

SBVRBN AND SBVRBP

Test Pressures Equal To or Less Than

1/2 PSIG (3.5 kPa)

1. Close equipment shutoff valve (see

Figure 31).

2. Pressurize supply piping system by ei-

ther opening propane/LP supply tank

valve for propane/LP gas burner sys-

tem or

opening main gas valve located

on or near gas meter for natural gas

burner system,

or using compressed air.

3. Check all joints from propane/LP sup-

ply tank or gas meter to equipment

shutoff valve (see Figure 32 for pro-

pane/LP or Figure 33 for natural, page

15). Apply commercial leak test solu-

tion to all gas joints. Bubbles forming

show a leak. Correct all leaks at once.

Pressure Testing Burner

System Gas Connections

1. Open equipment shutoff valve (see Fig-

ure 31).

2. Open propane/LP supply tank valve for

propane/LP burner system or main gas

valve located on or near gas meter for

natural gas burner system.

3. Make sure control knob of burner sys-

tem is in the OFF position.

4. Check all joints from equipment shutoff

valve to thermostat gas valve (see Fig-

ure 32 for propane/LP or Figure 33 for

natural, page 15). Apply commercial

leak test solution to all gas joints.

Bubbles forming show a leak. Correct

all leaks at once.

5. Light burner system (see Lighting In-

structions, page 19). Check all other in-

ternal joints for leaks.

6. Turn off burner system (see To Turn Off

Gas to Appliance, page 19).

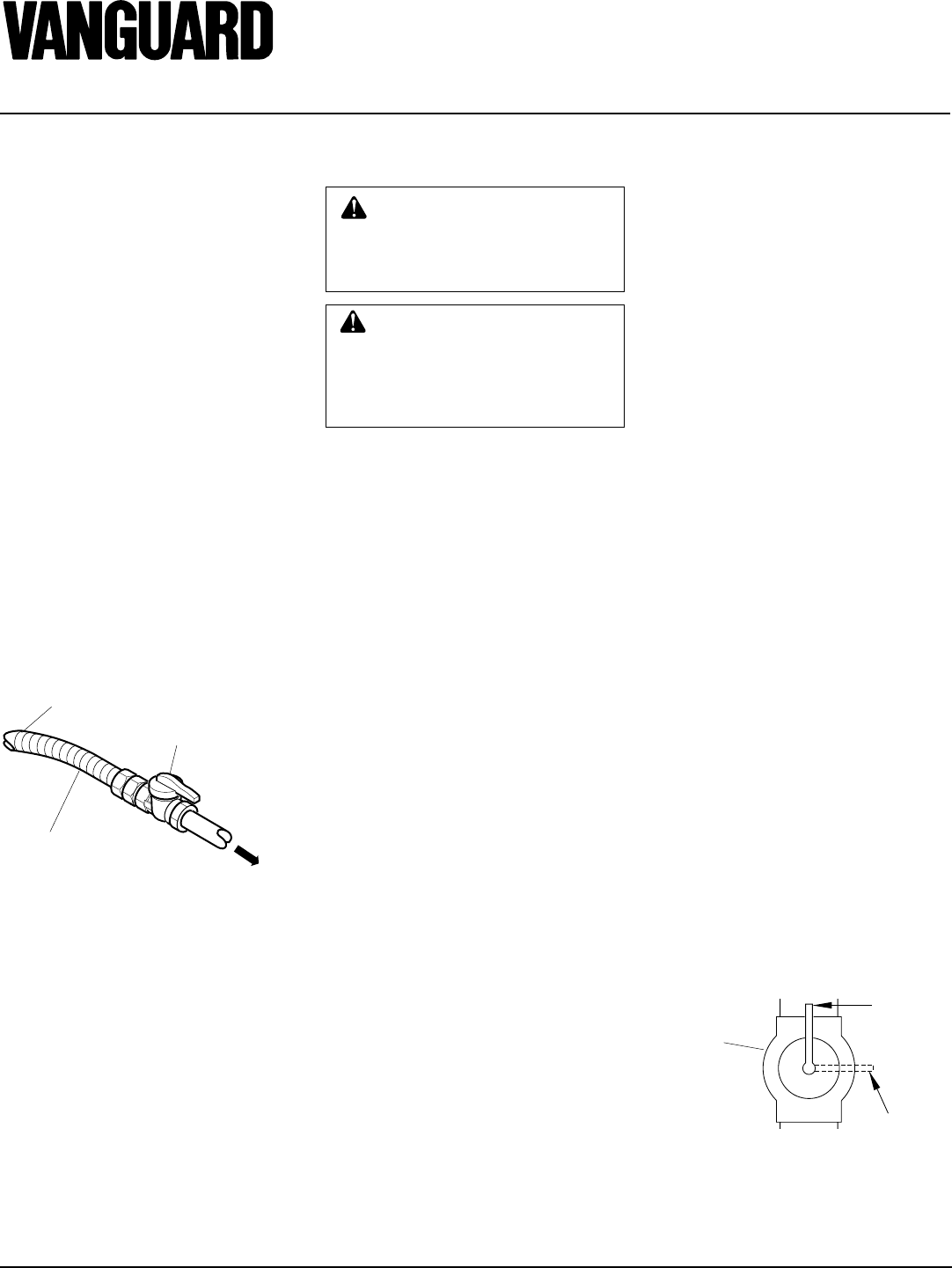

Figure 31 - Equipment Shutoff Valve

ON

POSITION

OFF

POSITION

Open

Closed

Equipment

Shutoff

Valve

Pressure Testing Gas Supply

Piping System

Test Pressures In Excess Of 1/2 PSIG

(3.5 kPa)

1.

Disconnect appliance with its appliance

main gas valve (control valve) and

equipment shutoff valve from gas

supply piping systems. Pressures in

excess of 1/2 psig (3.5 kPa) will damage

burner system gas regulator.

2. Cap off open end of gas pipe where

equipment shutoff valve was con-

nected.

3. Pressurize supply piping system by ei-

ther opening propane/LP supply tank

valve for propane/LP gas burner sys-

tem or

opening main gas valve located

on or near gas meter for natural gas

burner system,

or using compressed air.

4. Check all joints of gas supply piping

system. Apply commercial leak test

solution to all gas joints. Bubbles form-

ing show a leak. Correct all leaks at

once.

5. Reconnect burner system and equip-

ment shutoff valve to gas supply. Check

reconnected fittings for leaks.

CHECKING GAS

CONNECTIONS

WARNING: Test all gas pip-

ing and connections for leaks

after installing or servicing. Cor-

rect all leaks at once.

WARNING: Never use an open

flame to check for a leak. Apply

commercial leak test solution to all

gas joints. Bubbles forming show

a leak. Correct all leaks at once.

Installation Items Needed

• 5/16" hex socket wrench or nut-driver

• sealant (resistant to propane/LP gas, not

provided)

1. Open lower door panel.

2. Route flexible gas line (provided by

installer) from equipment shutoff valve

to burner system (see Figure 30). Route

flexible gas supply line and attach to

valve.

3. Check all gas connections for leaks. See

Checking Gas Connections.

CONNECTING STOVE/

BURNER SYSTEM TO GAS

SUPPLY

To Flare Fitting on

Control Valve

Flexible Gas Line from

Equipment Shutoff Valve

Provided by Installer

Equipment

Shutoff Valve

To Gas

Supply

(Natural)

To External

Regulator

(Propane/LP)

Figure 30 - Flexible Gas Line

CAST IRON STOVE

AND B-VENT

BURNER SYSTEM

INSTALLATION

Continued