VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

F25154 (February 2004) Page 16 of 48

SERVICE PROCEDURES AND ADJUSTMENTS

WARNING: CERTAIN PROCEDURES IN THIS SECTION REQUIRES ELECTRICAL TEST OR

MEASUREMENTS WHILE POWER IS APPLIED TO THE MACHINE. EXERCISE EXTREME CAUTION AT ALL

TIMES. IF TEST POINTS ARE NOT EASILY ACCESSIBLE, DISCONNECT POWER AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES, ATTACH TEST EQUIPMENT AND REAPPLY POWER TO TEST.

BOILER

Inspection

The boiler should be inspected for excessive lime

scale build-up in a time frame dependant on the

quality of the local water supply and steamer usage.

In hard water areas or for steamers heavily used, a

more frequent interval should be used. This

inspection consists of an internal examination and

cleaning of the boiler, an examination of the two

hanging descalers (cathodic protectors) and for lime

scale build-up on the water level probes. Also, check

all boiler controls, including the pressure switches.

Periodic service must be performed as outlined in

the BOILER procedures. See WATER

CONDITIONING under GENERAL.

Clean-Out

1. Turn power switch off and allow boiler to

blowdown/drain.

2. Remove heating element mounting plate as

outlined in REMOVAL AND REPLACEMENT

OF PARTS.

3. Inspect descalers (cathodic protectors) as

outlined under DESCALER (CATHODIC

PROTECTOR) in this section.

4. Remove both descalers from boiler.

5. Clean interior of boiler using a wire brush or

equivalent.

A. Dislodge and remove all loose scale from

boiler. All loose debris must be removed

from the boiler.

B. Remove all loose scale form the heating

element mounting plate.

C. Clean the mating surfaces of the heating

element mounting plate and boiler.

6. Check boiler drain and drain line plumbing for

obstructions.

A. Remove cap and strainer screen from

strainer body. Separate screen from cap

and clean debris from screen.

B. Through the front opening in boiler, flush

out the boiler and drain line plumbing with

clean water.

7. Check probe housing and water level probes for

scale build-up and clean as necessary.

8. Install descalers (cathodic protectors).

9. Install heating element mounting plate.

10. Install heating elements.

11. Check for proper operation.

Deliming

Refer to the water filtration system manual supplied

with steamer for specific instructions.

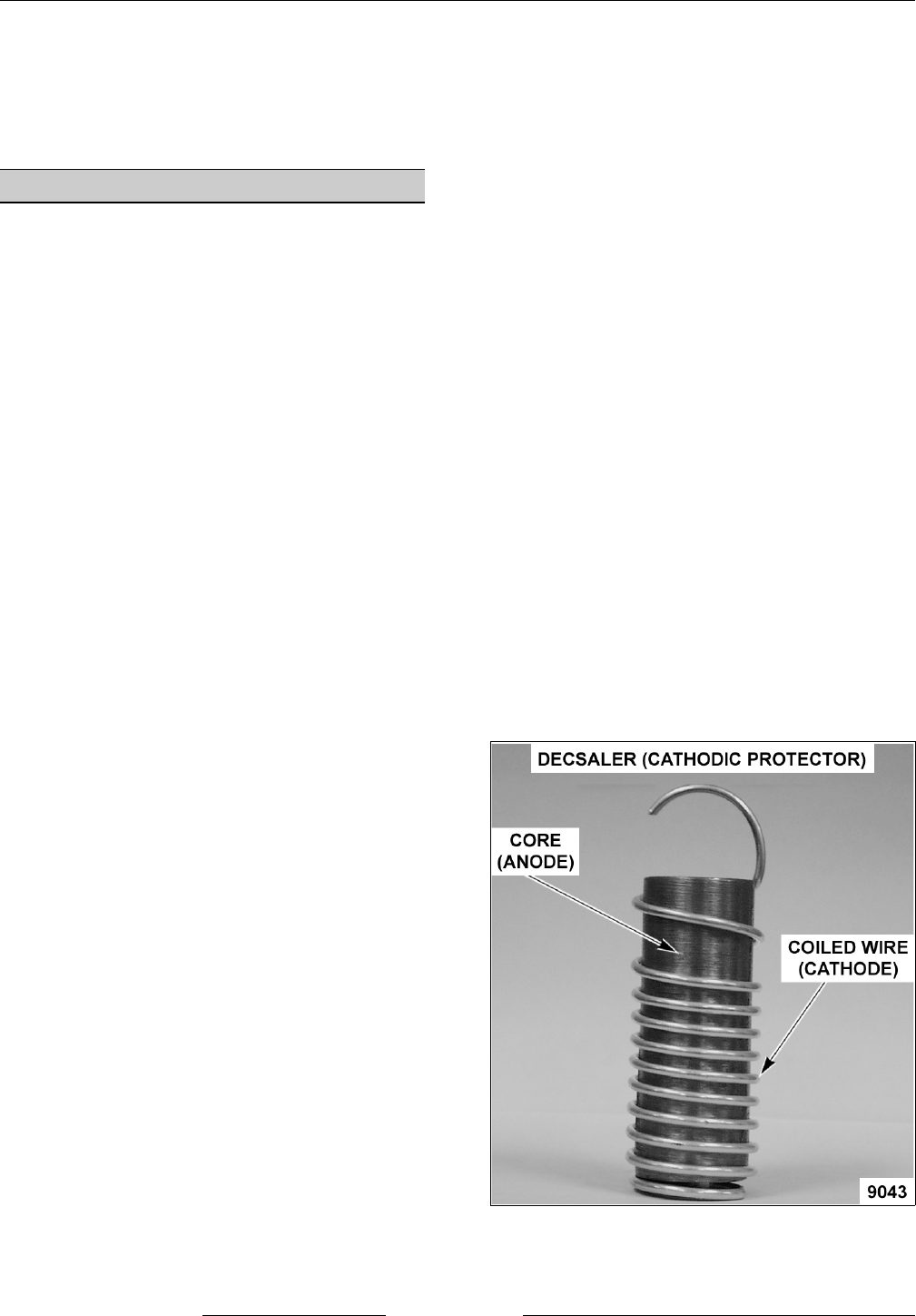

Descaler (Cathodic Protector)

Two descalers are installed inside the boiler and are

used as a preventative measure to:

• Reduce scale deposit build-up

• Help remove existing scale deposits

• Inhibit boiler and component corrosion

The descaler has a coiled wire (cathode) wrapped

around a solid cylindrical core (anode) that hangs by

an open loop from the front horizontal support rod

inside the boiler.

The descaler materials serve as a sacrificial anode

and cathode combination that chemically react with

the contents of the boiler to meet the three objectives

outlined above.