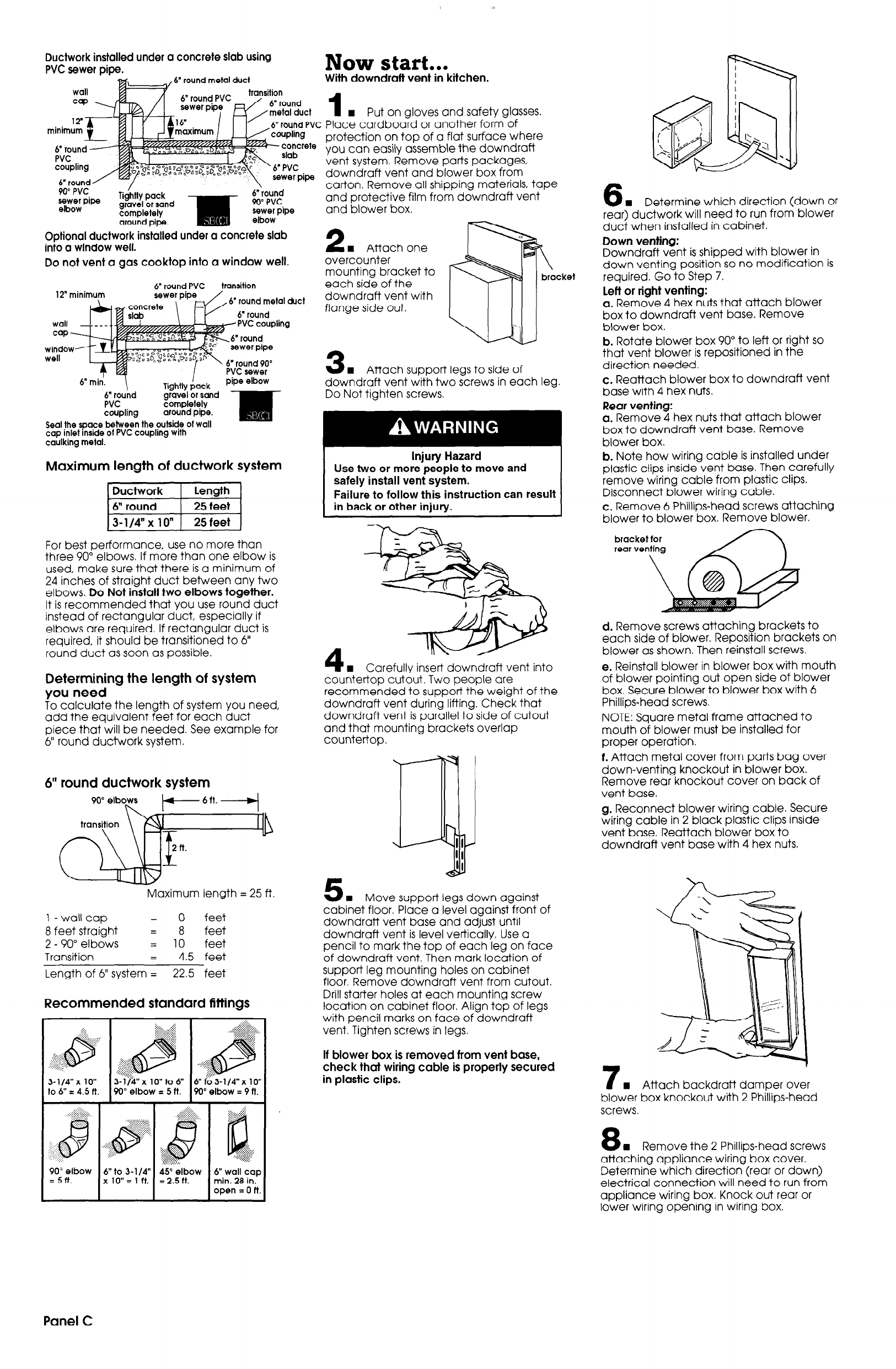

Ductwork installed under a concrete slab using

PVC sewer pipe.

Optional ductwork installed under a concrete slab

into a window well.

Do

not vent a

gas

cooktop into a window well,

12” minimum

6”

round PVC

concreie

slab

transition

6” round metal duct

6” round

T

6” min.

I

PVC sewer

Tiahtlv

oock

pipe elbow

6” rouhd

‘-G----I r --.-

PVC

gravel or sand

completely

coupling

around pipe.

Seal the space between the outside of wall

cap inlet inside of PVC coupling with

caulking metal.

Maximum length of ductwork system

For best performance, use no more than

three 90” elbows. If more than one elbow is

used, make sure that there is a minimum of

24 inches of straight duct between any two

elbows. Do Not install two elbows together.

It is recommended that you use round duct

instead of rectangular duct, especially if

elbows are required. If rectangular duct is

required, it should be transitioned to 6”

round duct as soon as possible.

Determining the length of system

you need

To calculate the length of system you need,

add the equivalent feet for each duct

piece that will be needed. See example for

6” round ductwork system.

6” round ductwork system

6ft. -4

lb

Maximum length = 25 ft.

I-wallcap = 0

feet

8 feet straight

= 8 feet

2 - 90” elbows

= 10 feet

Transition

=

4.5 feet

Length of 6” system = 22.5 feet

Recommended standard fittings

:::::::; ..:::::

. . . . . -.- . . . . . -.

:i::

...-...-.-.-.-.-.-..i

. ..-.-.-.-..-... :

..i-I~~~ ~~~ ...~~~:-.

.::.:::.:>.:::; .-:..

3-l/&x 10” 3-l/$x lO”to6” 6”f;63-1/4”xlo”

to 6” = 4.5 ft.

90” elbow = 5 ft.

90” elbow = 9 ft.

PO; ;,lbow

Now start...

With downdraft vent in kitchen.

1

n

Put on gloves and safety glasses.

Place cardboard or another form of

protection on top of a flat surface where

you can easily assemble the downdraft

vent system. Remove parts packages,

downdraft vent and blower box from

carton. Remove all shippina materials, tape

and protective film fro’& downdraft vent

and blower box.

2

w Attach one

overcounter

mounting bracket to

each side of the

downdraft vent with

flange side out.

3

w Attach supper? legs to side of

downdraft vent with two screws in each leg.

Do Not tighten screws.

Injury Hazard

Use two or more people to move and

safely install vent system.

Failure to follow this instruction can result

in back or other injury.

4

w Carefullv insert downdraft vent into

countertop cut&t. Two people are

recommended to support the weight of the

downdraft vent during lifting. Check that

downdraft vent is parallel to side of cutout

and that mounting brackets overlap

countertop.

w Move support legs down against

cabinet floor. PI&e a le;el against-front of

downdraft vent base and adjust until

downdraft vent is level vertically. Use a

pencil to mark the top of each leg on face

of downdraft vent. Then mark location of

support leg mounting holes on cabinet

floor. Remove downdraft vent from cutout.

Drill starter holes at each mounting screw

location on cabinet floor. Align top of legs

with pencil marks on face of downdraft

vent. Tighten screws in legs.

If blower box is removed from vent base,

check that wiring cable is properly secured

in plastic clips.

6

H Determine which direction (down or

rear) ductwork will need to run from blower

duct when installed in cabinet.

Down venting:

Downdraft vent is shipped with blower in

down venting position so no modification is

required. Go to Step 7.

left or right venting:

a. Remove 4 hex nuts that attach blower

box to downdraft vent base. Remove

blower box.

b. Rotate blower box 90” to left or right so

that vent blower is repositioned in the

direction needed.

c. Reattach blower box to downdraft vent

base with 4 hex nuts.

Rear venting:

a. Remove 4 hex nuts that attach blower

box to downdraft vent base. Remove

blower box.

b. Note how wiring cable is installed under

plastic clips inside vent base. Then carefully

remove wiring cable from plastic clips.

Disconnect blower wiring cable.

c. Remove 6 Phillips-head screws attaching

blower to blower box. Remove blower.

bracket for

real venting

\

d. Remove screws attaching brackets to

each side of blower. Reposition brackets on

blower as shown. Then reinstall screws.

e. Reinstall blower in blower box with mouth

of blower pointing out open side of blower

box. Secure blower to blower box with 6

Phillips-head screws.

NOTE: Square metal frame attached to

mouth of blower must be installed for

proper operation.

f. Attach metal cover from parts bag over

down-venting knockout in blower box.

Remove rear knockout cover on back of

vent base.

g. Reconnect blower wiring cable. Secure

wiring cable in 2 black plastic clips inside

vent base. Reattach blower box to

downdraft vent base with 4 hex nuts.

7

w Attach backdraft damper over

blower box knockout with 2 Phillips-head

screws.

8

n

Remove the 2 Phillips-head screws

attaching appliance wirini box cover.

Determine which direction (rear or down)

electrical connection will need to run from

appliance wiring box. Knock out rear or

lower wiring opening in wiring box.

Panel

C