30

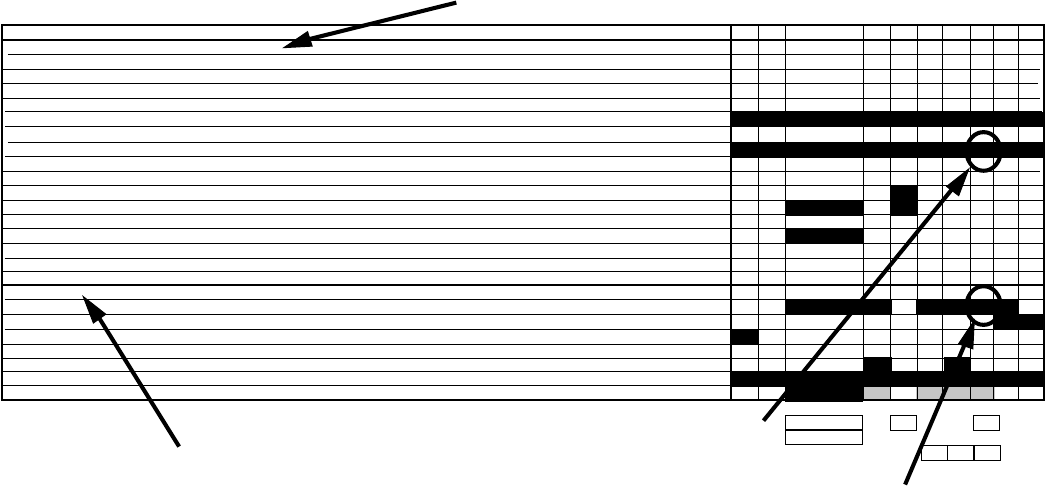

Using the Common Cycle Time Chart

To confirm the correct operation of a cycle or properly diagnosis a malfunction, the following informa-

tion must be determined:

• Does the model have a Soil Sensor?

• What cycle was chosen?

• What Cycle Option was chosen?

• What is the first fill water temperature? (Quick Clean / Time Saver Cycle only)

Proceed with the following steps:

1. Start the selected cycle and program the unit for Rapid Advance service feature. (See page

36).

2. Advance through the intervals to the one that will operate the load or perform the function to be

checked.

3. If the load does not operate, refer to the wiring diagram or applicable strip circuit to determine

what connections and components to check. (See Section Five - TECH TIPS.)

4. Whenever possible, check components for resistance or continuity. On components where

resistance or continuity checks are not reliable, conduct voltage checks.

Wash Motor should be running

“CYCLE PROGRESSION & STATUS INDICATORS

PROG BAR W1

PROG BAR W2

WASHING (PROG BAR W3)

PROG BAR R1

CIRC (PROG BAR R2) (This LED will be labeled as ‘WASHING’ on models that use it, but it is on during all Wash and Rinse Periods)

RINSING

DRYING

SOAKING NOTE 7

SOAKING/SENSING NOTE 7

ADD-A-DISH

WATER HEATING (THERMAL HOLD INDICATOR) NOTE 6

SANITIZED NOTE 8,15

CLEAN NOTE 8

OUTPUT LOADS

WASH MOTOR (MAIN WINDING)

DRAIN MOTOR NOTE 2

FILL NOTE 2

APF ENABLED INTERVALS -Max # of APF Purges allowed in Interval NOTE 2

DETERGENT / RINSE AID DISPENSER

VENT

HEATER NOTES 4,10,11,16

17

16 15 14 13 12 11 10 9 8

3

15

94

11 11 11

Rinsing Indicator should be lIt

Fig. 4-4

(2)

(1)