98

6

6

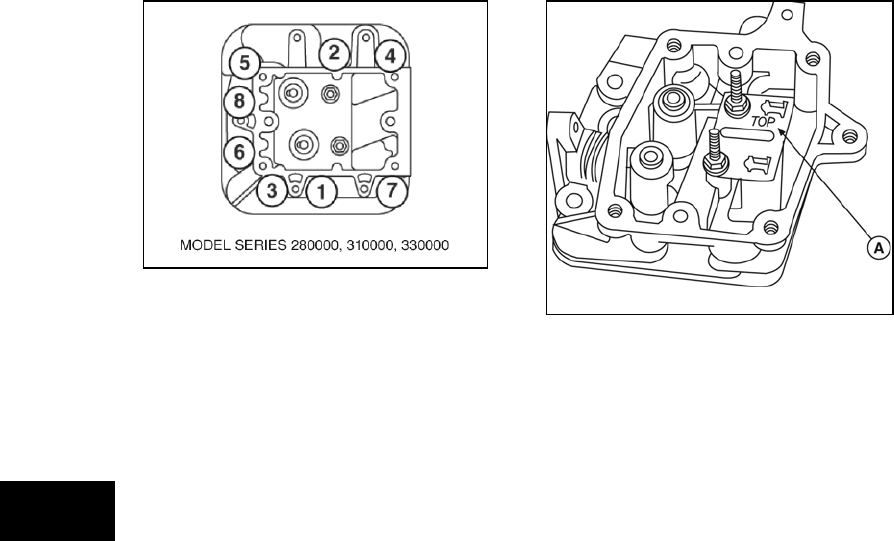

Figure 18

NOTE: Do not torque each screw in one step as

it may result in a warped cylinder head. Step-

torque all screws to approximately 1/3 of final

torque value, then to 2/3 final torque value, then

finish at final torque value.

3. Install push rod guide and rocker arm

studs (models 97700, 99700). Torque

studs to values listed in Section 12 -

Engine Specifications.

-OR-

4. Install rocker arm studs (models 110000,

120000, 150000). Torque to values listed

in Section 12 - Engine Specifications.

NOTE: Early production of vertical models

110000 and 120000 require a jam nut to be

threaded approximately half way up the threads

of the stud before installation into the head.

5. Install push rods through guides and into

same positions as removed. Ensure rods

are seated in valve tappets. Place valve

stem caps (if used) on valve stems.

6. Place rocker arms and rocker balls on

rocker arm studs (Figure 19). Install rocker

arm screws and/or lock nuts on studs and

tighten until there is zero clearance

between the valve stem caps and the

rocker arms.

Figure 19

7. Rotate crankshaft at least twice to ensure

proper movement of the push rods and

rocker arms.

8. Adjust valve clearance per Section 1, then

install a new rocker cover gasket and the

rocker cover. Torque screws to values

listed in Section 12 - Engine

Specifications.