117

8

8

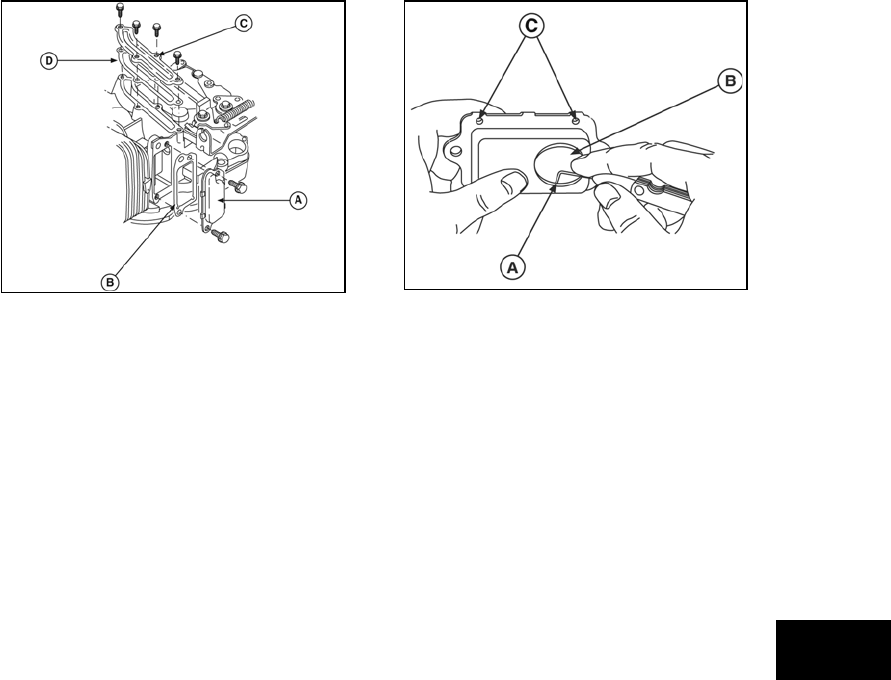

Figure 2

Check Breather

1. Check for movement of the disc valve in

the breather assembly. If disc is stuck or

binding, replace the breather assembly.

2. Visually inspect the assembly for warping,

wear, or damage. If these conditions are

found, replace the breather assembly.

3. Inspect oil drain-back holes (C, Figure 3)

to make sure they are open. Clean as

needed.

4. Using 0.045” (1.14 mm) wire gauge, check

clearance between the disc valve (B) and

the housing (A). If gauge can be inserted,

replace the breather assembly.

NOTE: Do not apply force to the wire gauge! The

disc valve is retained by an internal bracket

which will be distorted if pressure is applied to

disc.

5. Inspect breather passage on top of

cylinder for debris and/or blockage.

Carefully clean this area if necessary,

ensuring passage holes are open.

Figure 3

Install Breather

1. Install new breather passage gasket and

breather passage cover on top of cylinder.

Torque four screws to values listed in

Section 12 - Engine Specification.

2. Place new breather gasket and breather

assembly on side of cylinder. Torque two

screws to values listed in Section 12 -

Engine Specification.

Service Breather - Vertical Models

280000, 310000 Early Production

Remove Breather

1. Remove breather tube from breather

assembly on side of cylinder.

2. Remove two screws, breather assembly,

and gasket. Discard gasket.

Check Breather

1. Check for movement of the disc valve in

the breather assembly. If disc is stuck or

binding, replace the breather assembly.

2. Visually inspect the assembly for warping,

wear, or damage. If these conditions are

found, replace the breather assembly.

3. Inspect oil drain-back holes (C, Figure 4)

to make sure they are open. Clean as

needed.

4. Using 0.045” (1.14 mm) wire gauge, check

clearance between the disc valve (B) and

the housing (A). If gauge can be inserted,

replace the breather assembly.