49

2

2

EQUIPMENT AFFECTING ENGINE OPERATION

Frequently, what appears to be a problem with

engine operation, such as hard starting or

vibration, may be the fault of the equipment

rather than the engine itself. Below are some

common symptoms and potential equipment-

related sources.

Hard Starting or Will Not Start

1. Check for a loose drive belt or a loose

blade, which will counteract engine

cranking effort.

2. Check for parasitic load; disengage

equipment controls before starting.

3. Check remote throttle/choke control for

proper adjustment.

4. Check interlock system for shorted wires,

loose or corroded connections, or

defective modules or switches.

Engine Won’t Stop

1. Check equipment stop switch.

2. Check for loose or disconnected

equipment stop switch wire.

3. Check engine ground wire harness.

Vibration

1. Check for bent or out-of-balance cutter

blades.

2. Check for loose, worn, or damaged drive

belts and pulleys.

3. Check for loose mounting bolts.

OIL GARD SYSTEMS

Engine Will Not Start, On/Off Switch Light

Flashes

1. Check engine oil level. If oil is between

ADD and FULL, go to next step. If low,

add oil to bring to FULL mark on dipstick.

If engine starts and runs, problem

corrected.

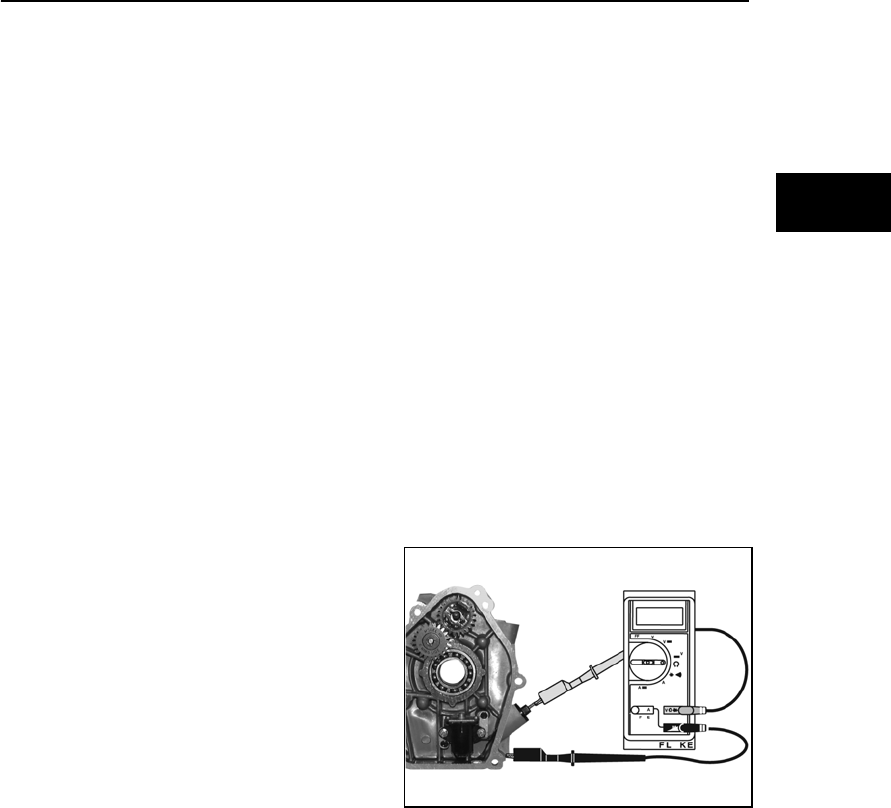

2. Disconnect wire from module to plug and

terminal assembly on crankcase cover.

Use Digital Multimeter #19464 to check

resistance.

3. Rotate selector to (Ohms) position.

4. Insert RED test lead into the V Ω

receptacle in the meter.

5. Insert BLACK test lead (B) into COM

receptacle.

6. Connect either test lead to plug and

terminal.

7. Connect other test lead to crankcase

cover (Figure 41). If meter reads Zero

resistance, replace sensor in crankcase

cover. If meter reads some resistance, go

to next step.

Figure 41

8. With module wire disconnected and not

touching ground, try to start the engine. If

engine starts, replace module. If engine

does not start, check Oil Gard wiring for

shorts to ground. Repair as needed.