142

10

10

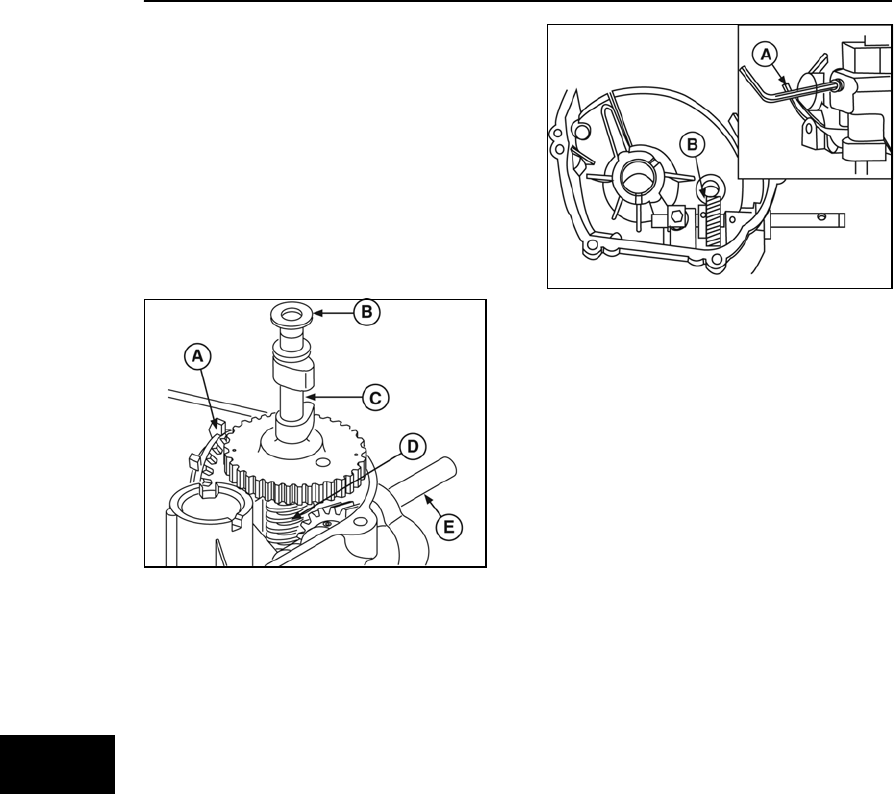

AUXILIARY PTO

Some models of the vertical shaft 110000 and

120000 engines were equipped with an auxiliary

PTO shaft. The auxiliary PTO shaft (E, Figure

23) extends through the side of the sump,

perpendicular to the crankshaft. Rotation can be

either clockwise or counterclockwise, as viewed

from the end of the shaft. The oil slinger (A),

camshaft (C), and worm gear (D) are pre-

assembled and must be serviced as a set.

NOTE: The clockwise system requires a thrust

washer (B) installed at the upper camshaft

journal. The counterclockwise system requires

the thrust washer be installed at the lower

journal, under the worm gear.

Figure 23

Remove Auxiliary PTO Drive Shaft

1. Remove all rust and burrs from

crankshaft, then remove sump.

2. To remove auxiliary PTO shaft from sump,

remove Allen screw (A, Figure 24) from

bottom of sump. The slinger, camshaft,

and worm gear assembly will remain in the

cylinder.

Figure 24

3. With a 3/16” pin punch, drive the roll pin in

the bevel gear (B) through the allen screw

hole.

4. Remove screw and PTO shaft stop then

slide out PTO shaft.

Inspection

Inspect all parts for evidence of wear or damage.

If replacement is required, ensure the correct

rotation set (clockwise or counterclockwise) is

chosen from the Illustrated Parts List.

Assemble Auxiliary PTO Drive Shaft

1. Place drive shaft in sump and push shaft

through bevel gear.

2. Line up holes in bevel gear and drive

shaft. Install new roll pin until it is centered

in gear.

3. Place shaft stop in groove of drive shaft

and install screw. Torque to values listed

in Section 12 - Engine Specifications.

4. Install allen screw in bottom of sump and

torque to values listed in Section 12 -

Engine Specifications.

5. Rotate assembly by hand to check for

binding.

6. Using new gasket, install sump to cylinder

according to instructions provided earlier

in this section.