Page 15

SERVICE

This section provides procedures for testing and

replacing various major components used in this

brewer should service become necessary. Refer to

Troubleshooting

for assistance in determining the

cause of any problem.

WARNING - Inspection, testing, and repair of electri-

cal equipment should be performed only by qualified

service personnel. The brewer should be disconnected

from the power source when servicing, except when

electrical tests are required and the test procedure spe-

cifically states to plug in the brewer.

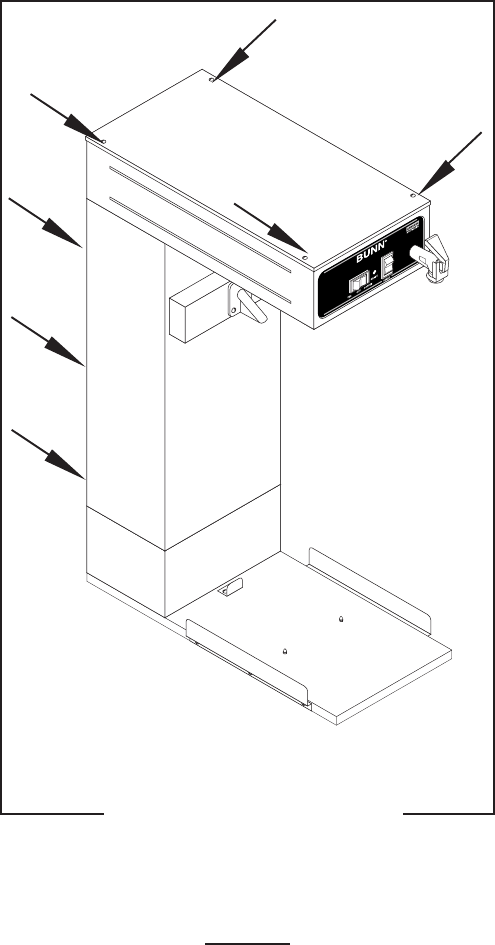

COMPONENT ACCESS

WARNING - Disconnect the brewer from the power

source before the removal of any panel or the replace-

ment of any component.

All components are accessible by the removal of

the top cover and rear inspection panel.

The top cover is attached with four #6-32 screws.

Removal of the top cover will allow access to TEA/OFF/

COFFEE switch, START switch, Control Board, limit

thermostat, temperature probe, thermal fuse and tank

heater,

The rear inspection panel is attached with six #8-

32 screws. Removal of the rear panel will allow access

to the solenoid valves and the .195 GPM flow control.

FIG. 1 COMPONENT ACCESS

P1808.40

Contents

Brew Solenoid Valve (Hot Coffee) ....................... 16

Brew Solenoid Valve (Iced Tea) .......................... 17

Dilution Solenoid Valve ....................................... 18

Limit Thermostat ................................................ 19

TEA/OFF/COFFEE Switch ..................................... 20

START Switch ..................................................... 21

Tank Heater ......................................................... 22

Temperature Probe ............................................. 23

Thermal Fuse ...................................................... 24

Control Board ..................................................... 25

Wiring Diagram .................................................. 26

29466 082200