4-1

LJS 24G SERIES FLATBOTTOM GAS FRYERS

CHAPTER 4: STARTUP AND OPERATING PROCEDURES

4.1 CLEANING

Note: All procedures should be performed as instructed in the current LJS Operations

Manual. In the absence of the LJS Operations Manual, the following procedures are offered

as a temporary solution.

New units are wiped clean with solvents at the factory to remove dirt, oil, and grease remaining

after the manufacturing process, and then coated with light oil. Prior to first use, boil out the frypot

(remove temperature sensor guard prior to cleaning frypot) as outlined in Section 4.4.1, Boil-Out

Procedure. (In KFC co-branded locations, do not boil out the fryer. Use the KFC-approved

procedure for cleaning the frypot.) Wash any accessories shipped with the unit in hot, soapy water

to remove remaining residue. Rinse the frying utensils with a solution of vinegar and water (1 pint

vinegar to 1/2 gallon of hot water) to neutralize any soap residue, then rinse with clean water and

thoroughly dry all surfaces.

NOTE: In KFC co-branded locations, boil out is NOT ALLOWED. Use KFC approved

procedure.

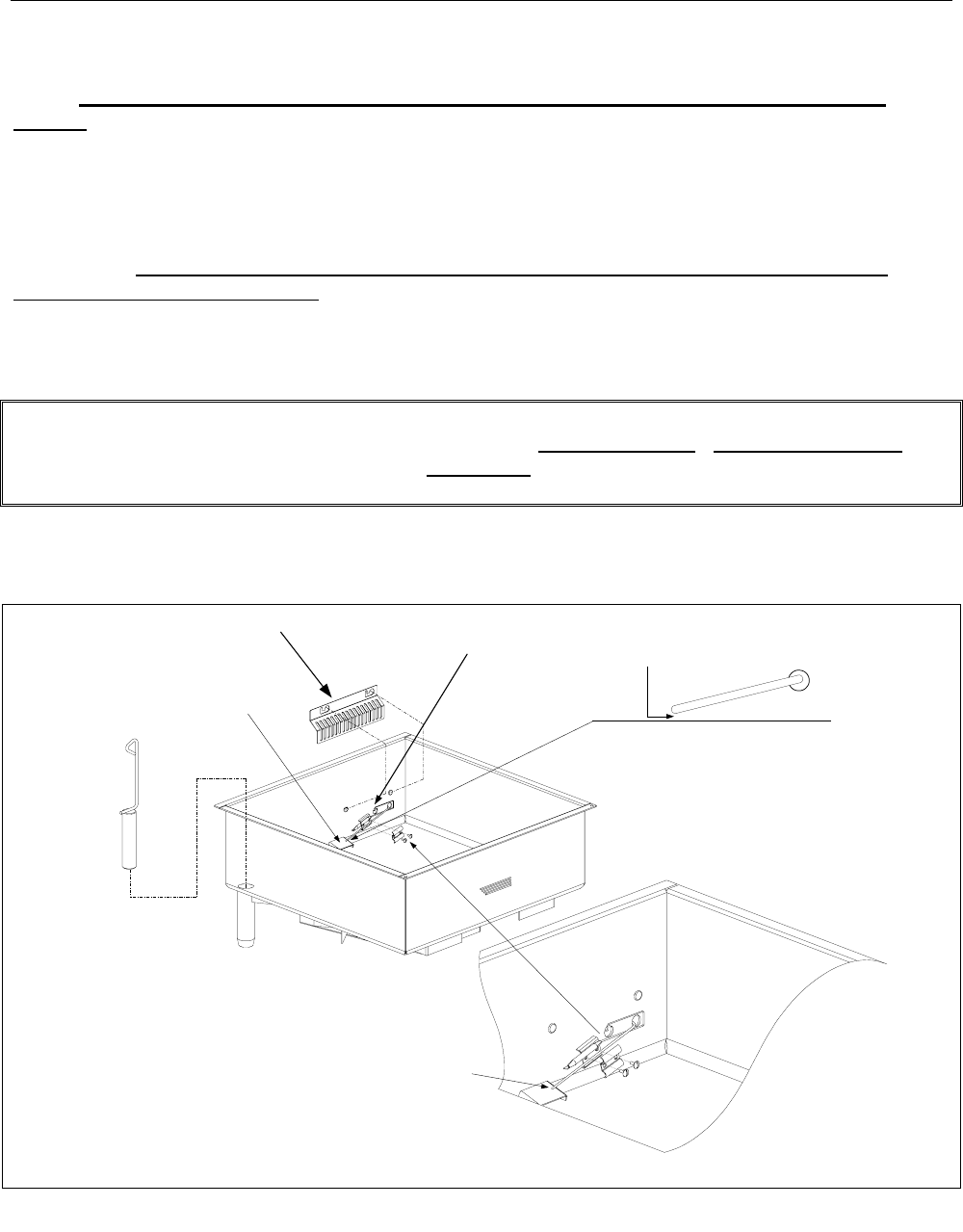

Ensure the sensor probe guard is replaced after cleaning to protect the sensor probe and high-limit

probe (Figure 1).

Sensor Probe Guard High-Limit/Temperature

Probe location

Frypot Drain Plug

Frypot Bottom

Frypots without probe-mounting

hardware: Ensure probe tip is 1/8" from

frypot bottom for proper temperature sensing.

Oil-Return Port (built-in filter

equipped systems only)

Frypots with probe-mounting hardware: No

special adjustment is required. Temperature probe

bulb will contact oil-return shield in built-in filtration-

equipped frypots.

Figure 1: Sensor probe guard, frypot drain plug and high-limit/sensor probe location.