5-10

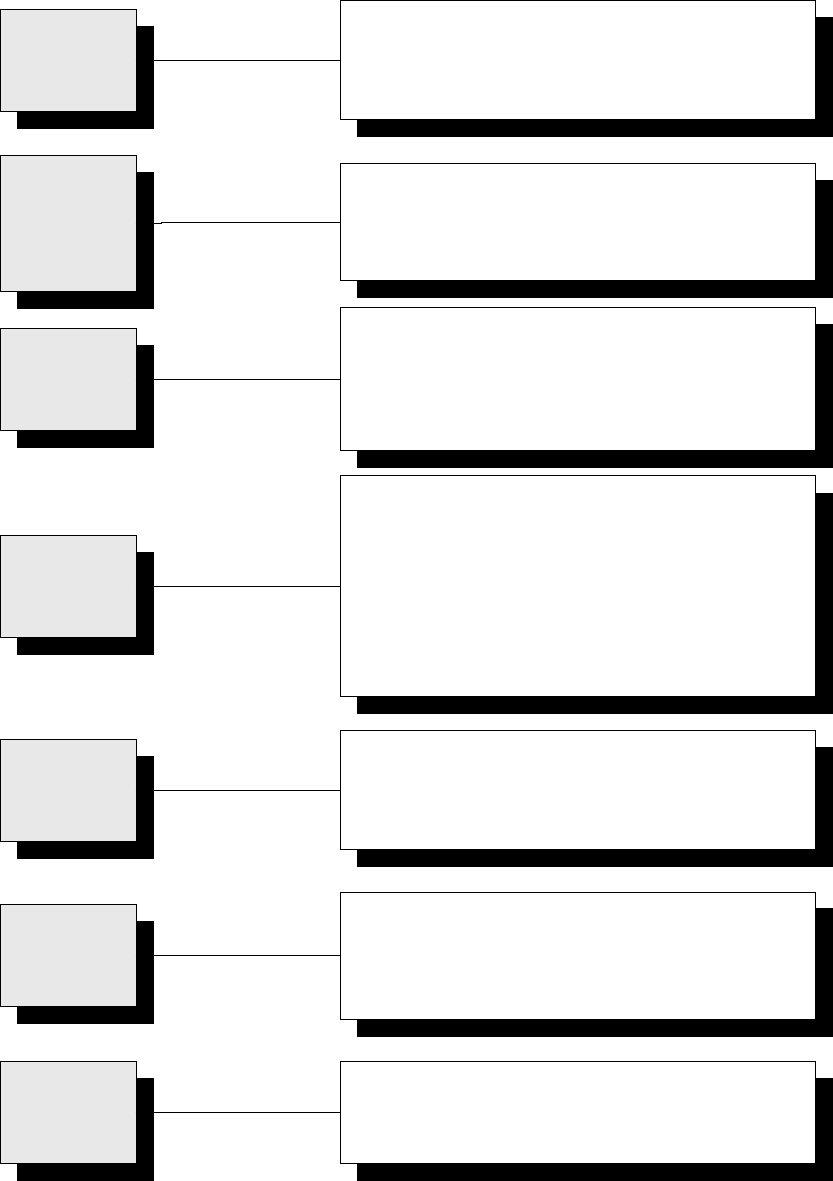

5.9 FILTER TROUBLESHOOTING

The problems and possible solutions covered are those most commonly encountered.

Pump won't

start.

y Return valve not fully open.

y Tripped circuit breaker.

y Incorrect or no line voltage.

y Failed return valve microswitch.

Pump stops

during

filtering

process.

Motor is hot.

y Allow motor to cool for at least 45 minutes and then

press thermal overload switch on motor. Also reset

the 7-amp circuit breaker.

Pump stops

and motor is

cool.

y Move filter handle to "OFF". Allow oil to cool then

empty pan. Verify filter leaf assembly is clean and

properly installed. Refill pan and restart process.

Pump starts

and abruptly

stops.

y Reset thermal overload.

y Verify wiring harness is properly connected; a

damaged harness should be replaced by an FASC.

y Pump is blocked. Call FASC for service.

y Filter pan suction tube is blocked. Use a thin,

flexible wire to unclog.

y Motor or 24 VAC transformer failed; contact an

authorized service technician for service.

Pumping is

erratic.

y Verify that filter leaf disconnect is properly attached

to filter system hose.

y Verify that filter leaf is properly installed in filter pan.

Oil not being

returned to

frypot.

y Solidified oil or sediment is likely clogging the return

line. Clear line.

y Clogged filter leaf.

After filtering,

fryer does not

operate

properly.

y Verify drain valve is fully closed.