18

IO-242C 05/05

using a heating value of approximately 1,000 Btu/hr, and should

not normally require change. Most cases will not require a change

at altitudes up to 7,500 feet. For use at altitudes in excess of 4,500

feet, refer to the following table for maximum input rates based on

altitude. Contact your local gas utility for the heating value of the

gas. Refer to National Fuel Gas Code ANSI Z223.1 and the

following section to calculate firing rates.

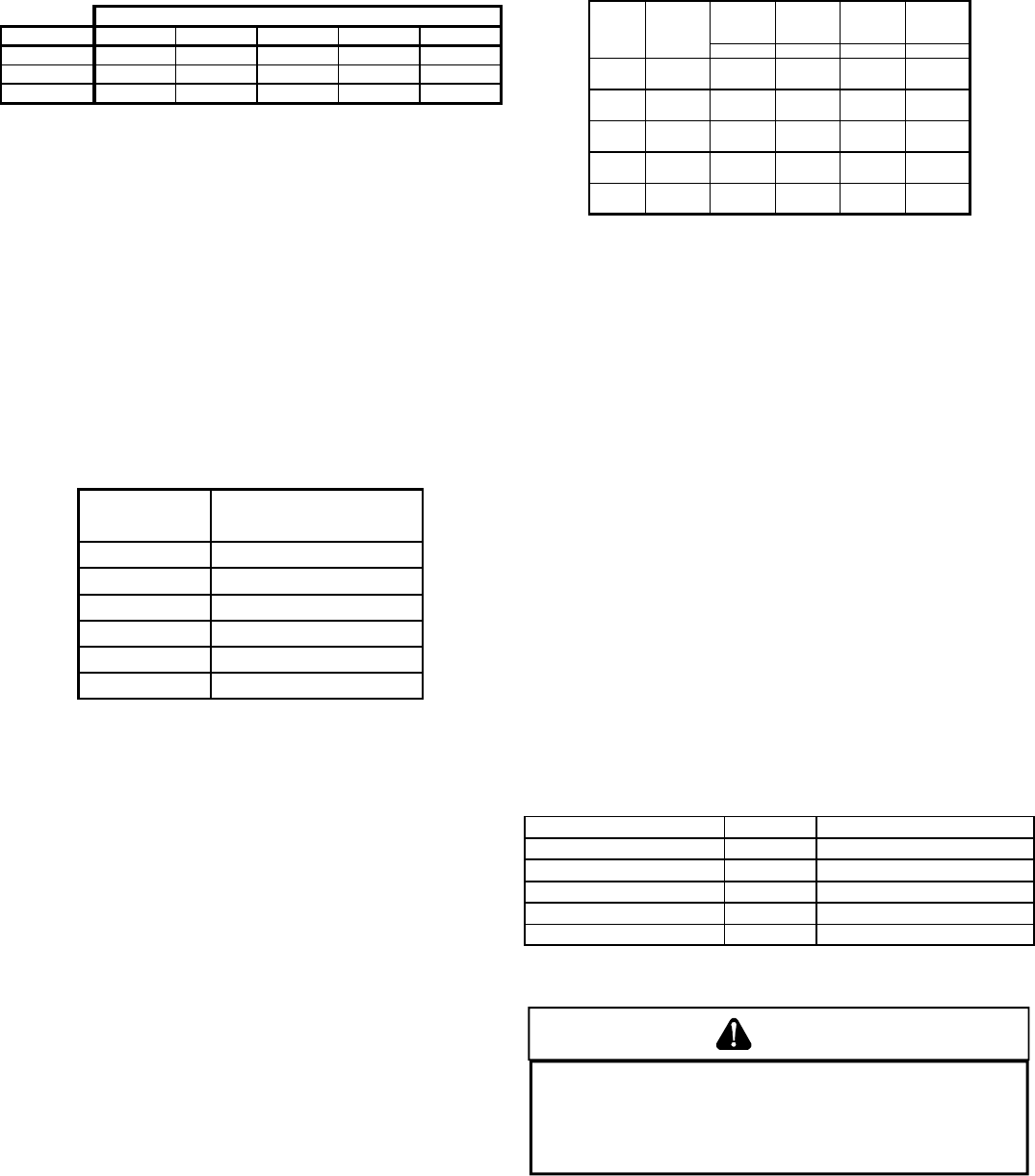

Maximium Firing Rates At Altitude

Model (Kbtu/hr)

Altitude (ft) 45 70 90 115 140

5,000 39,000 58,500 78,000 97,500 117,000

7,500 35,000 52,500 70,000 87,500 105,000

10,000 34,000 51,000 68,000 77,000 92,400

* Firing rates may be lower than listed in table

It is important to check and adjust the input rate of the furnace to

prevent an overfiring situation. Overfiring can cause premature

heat exchanger failure. The input is controlled by the supply

pressure, orifice size, manifold pressure and heating (calorific)

value of the gas.

The supply pressure must be measured with this and all other

gas burning appliances in operation. The supply pressure must

be adjusted to the pressure range stated on the series and rating

plate. Applications for altitudes in excess of 4,500 feet usually

require an orifice change. Alternately standard de-rate for altitude

from National Fuel Gas Code ANSI Z223.1 of 4% per 1000’ may

be taken. Refer to the most recent version of ASNI Z223.1 for

correct gas orifice. The orifices must be selected using the table

below. The furnace derate is 4% for each 1,000 feet above sea

level. This table is based upon a heating value of approximately

1,000 Btu/ft

3

NAT. GAS

ORIFICE SIZE

0 - 2,000 #43

3,000 #44

4,000 #44

5,000 #45

6,000 #45

7,000 #46

ALTITUDE

The input to the furnace must be checked AFTER reorificing.

For altitudes above 4,500 feet, refer to appropriate section of the

National Fuel Gas Code, ANSI Z223.1. To calculate the input of the

furnace for installations in altitudes over 7,000 feet, use the

following formula:

Corrected Input = Series & Rating Plate Input - (Altitude X .04) X

(Series & Rating Plate Input / 1000)

Example:

Corrected input for a 90,000 Btu/hr. appliance installed at an

altitude of 6,000 ft. utilizing natural gas with a heating value of

1,000 Btu/ft

3

is determined by-

Corrected Input = 90,000 - (6,000 X .04) X (90,000 / 1,000)

Corrected Input = 90,000 - (240 X 90)

Corrected Input = 90,000 - 21,600

Corrected Input = 68,400

Using the orifices sized as shown in the table for 6,000 feet (#45),

a meter time of 52.6 seconds is measured. The actual firing rate

of the furnace is:

FIRING R ATE

Input = 1,000 (heating value of the gas) X 3600 (constant) / 52.6

(meter time for 1 ft

3

of gas)

Input = 3,600,000 / 52.6

Input = 68,400 Btu/h

METER TIME IN MINUTES AND SECONDS FOR NORMAL INPUT RATING

OF

FURNACES EQUIPPED FOR USE WITH NATURAL GAS

INP UT M ETER

SIZE

HEAT

VALUE

HEAT

VALUE

HEAT

VALUE

HEAT

VALUE

Btu/hr FT

3

900 1,000 1040 1,100

MIN. SEC. MIN.SEC MIN. SEC. MIN. SEC.

1 1 21 1 30 1 33 1 39

10 13 30 15 00 15 36 16 30

1 0 54 1 00 1 03 1 06

10 9 00 10 10 10 24 11 00

1 0 41 0 45 0 47 0 50

10 6 45 7 30 7 48 8 15

1 0 32 0 36 0 37 0 40

10 5 24 6 00 6 14 6 36

1 0 27 0 30 0 31 0 33

10 4 30 5 00 5 12 5 30

120,000

40,000

60,000

80,000

100,000

In Canada, the series and rating plate input for the furnace apply

to installations up to 4,500 feet (1370m) above sea level. Canadian

certification applies to the installations of up to 4,500 feet above

sea level. Installations above 4,500 feet are subject to acceptance

by the local authorities having jurisdiction.

Do not derate the furnace by adjusting the manifold pressure to a

lower pressure than specified on the furnace rating plate. The

combination of the lower air density and a lower manifold pressure

will prohibit the burner orifice from drawing the proper amount of

air into the burner. This may cause incomplete combustion,

flashback, and possible yellow tipping.

In some areas the gas supplier may artificially derate the gas in

an effort to compensate for the effects of altitude. If the gas is

artificially derated, the appropriate orifice size must be determined

based upon the BTU/ft

3

content of the derated gas and the altitude.

Refer to the National Fuel Gas Code, NFPA 54/ANSI Z223.1, and

information provided by the gas supplier to determine the proper

orifice size.

Some models require a pressure switch change due to the reduced

air density above certain altitudes. Refer to the following table to

determine proper pressure switch settings for your application.

A different pressure switch may be required at high altitude

regardless of the BTU/ft

3

content of the fuel used. Contact your

distributor for appropriate altitude ranges and pressure switch

kits.

Pressure Switch Changes

Furnace input Kbtu/hr Altitude (ft) Switch Setting (inches w.c.)

45 8000' 0.5

5

70 N

R

90* 8000' 0.

6

11

5

N

R

14

0

N

R

* 904BNA does not require a switch change

PROPANE GAS CONVERSION

WARNING

POSSIBLE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH MAY OCCUR IF

THE CORRECT CONVERSION KITS ARE NOT INSTALLED.

T

HE APPROPRIATE KITS

MUST BE APPLIED TO INSURE SAFE AND PROPER FURNACE OPERATION.

A

LL

CONVERSIONS MUST BE PERFORMED BY A QUALIFIED INSTALLER OR SERVICE

AGENCY.