21

IO-242C 05/05

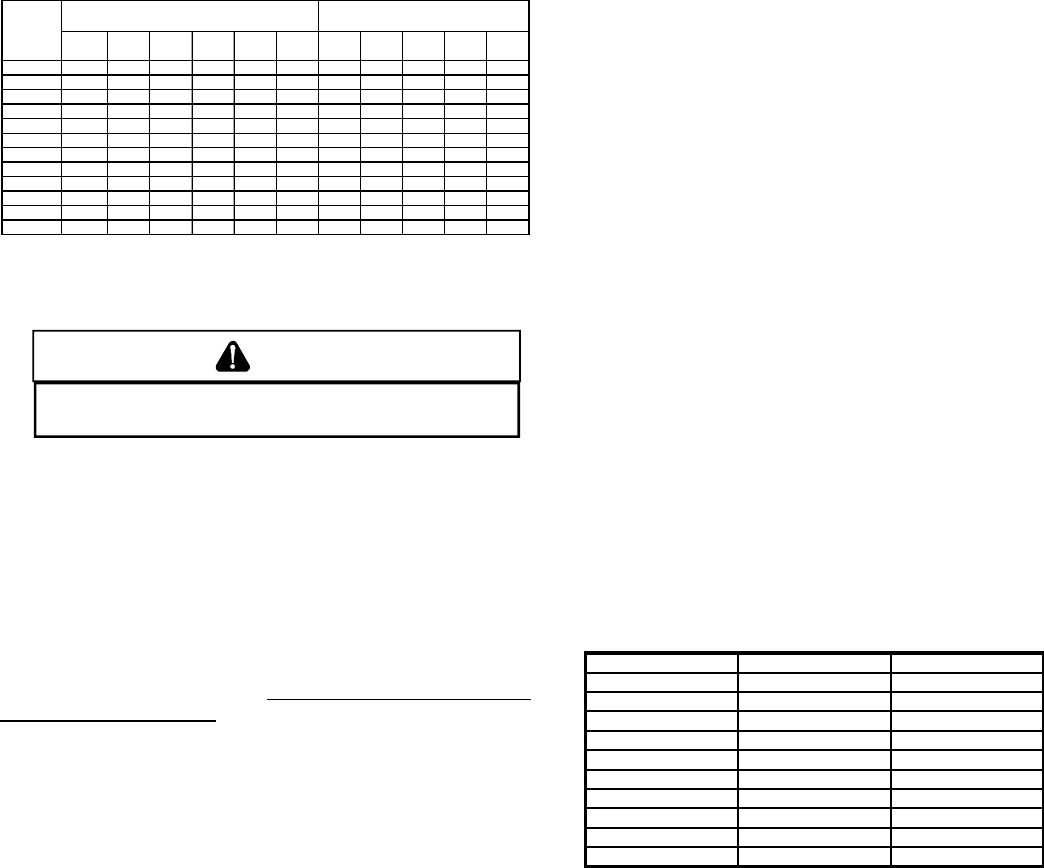

3/8" 1/2" 5/8" 3/4" 7/8" 1-1/8" 1/2" 3/4" 1" 1-1/4" 1-1/2"

10 39 92 199 329 501 935 275 567 1,071 2,205 3,307

20 26 62 131 216 346 630 189 393 732 1,496 2,299

30 21 50 107 181 277 500 152 315 590 1,212 1,858

40 19 41 90 145 233 427 129 267 504 1,039 1,559

50 18 37 79 131 198 376 114 237 448 91 1,417

60 16 35 72 121 187 340 103 217 409 834 1,275

80 13 29 62 104 155 289 89 185 346 724 1,066

100 11 26 55 90 138 255 78 162 307 630 976

125 10 24 48 81 122 224 69 146 275 567 866

150 9 21 43 72 109 202 63 132 252 511 787

200 8 19 39 66 100 187 54 112 209 439 665

250 8 17 36 60 93 172 48 100 185 390 590

Sizing Between First and Second Stage Regulator*

Maximum Propane Capacities listed are based on 2 psig pressure drop at 10 psig setting.

Capacities in 1,000 BTU/hour.

Pipe or

Tubing

Length,

Feet

Nominal Pipe Size

Schedule 40

Tubing Size, O.D. Type L

X. CIRCULATING AIR AND FILTERS

Ductwork - Air

WARNING

N

EVER ALLOW THE PRODUCTS OF COMBUSTION, INCLUDING CARBON

MONOXIDE, TO ENTER THE RETURN DUCTWORK OR CIRCULATION AIR SUPPLY.

Duct systems and register sizes must be properly designed for

the CFM and external static pressure rating of the furnace.

Ductwork should be designed in accordance with the

recommended methods of “Air Conditioning Contractors of

America” Manual D.

A duct system must be installed in accordance with Standards of

the National Board of Fire Underwriters for the Installation of Air

Conditioning, Warm Air Heating and Ventilating Systems.

Pamphlets No. 90A and 90B.

A closed return duct system must be used, with the return duct

connected to the furnace. NOTE: Ductwork must never be attached

to the back of the furnace. Supply and return connections to the

furnace may be made with flexible joints to reduce noise

transmission. To prevent the blower from interfering with combustion

air or draft when a central return is used, a connecting duct must

be installed between the unit and the utility room wall. A room,

closet, or alcove must not be used as a return air chamber.

When the furnace is used in connection with a cooling unit, the

furnace should be installed in parallel with or on the upstream side

of the cooling unit to avoid condensation in the heating element.

With a parallel flow arrangement, the dampers or other means

used to control the flow of air must be adequate to prevent chilled

air from entering the furnace and, if manually operated, must be

equipped with means to prevent operation of either unit unless

the damper is in the full heat or cool position.

When the furnace is installed without a cooling coil, it is

recommended that a removable access panel be provided in the

outlet air duct. This opening shall be accessible when the furnace

is installed and shall be of such a size that the heat exchanger

can be viewed for visual light inspection or such that a sampling

probe can be inserted into the airstream. The access panel must

be made to prevent air leaks when the furnace is in operation.

When the furnace is heating, the temperature of the return air

entering the furnace must be between 55°F and 100°F.

When a furnace is installed so that supply ducts carry air circulated

by the furnace to areas outside the space containing the furnace,

the return air shall also be handled by a duct sealed to the furnace

casing and terminating outside the space containing the furnace.

FILTERS - READ THIS SECTION BEFORE INSTALLING THE

RETURN A IR D UCTWORK

Filters must be used with this furnace. Discuss filter maintenance

with the building owner. Filters do not ship with this furnace, but

must be provided by the installer. Filters must comply with UL900

or CAN/ULCS111 standards. If the furnace is installed without

filters, the warranty will be voided.

NOTE: An undersized opening will cause reduced airflow. The

bottom return is set up as a knock out.

UPRIGHT INSTALLATIONS

Depending on the installation and/or customer preference, differing

filter arrangements can be applied. Filters can be installed in the

central return register or a side panel external filter rack kit

(upflows), or the ductwork above a counterflow furnace. As an

alternative, a media air filter or electronic air cleaner can be used

as the requested filter. The following figures show possible filter

locations.

CIRCULATION A IR F ILTERS

One of the most common causes of a problem in a forced air

heating system is a blocked or dirty filter. Circulating air filters

must be inspected monthly for dirt accumulation and replaced if

necessary. Failure to maintain clean filters can cause premature

heat exchanger failure.

A new home may require more frequent replacement until all

construction dust and dirt is removed. Circulating air filters are to

be installed in the return air duct external to the furnace cabinet.

FURNACE INPUT FILTER SIZE TYPE

45M

160 in

2

permanent

68M

241 in

2

permanent

90M

320 in

2

permanent

115M

400 in

2

permanent

135M

370 in

2

permanent

45M

320 in

2

disposable

68M

483 in

2

disposable

90M

640 in

2

disposable

115M

800 in

2

disposable

135M

738 in

2

disposable

PERMANENT NOMINAL 600 C.F.M.

DISPOSABLE NOMINAL 300 C.F.M.

MINIMUM FILTER SIZES

HORIZONTAL I NSTALLATIONS

Filters must be installed in either the central return register or in

the return air duct work.

XI. SEQUENCE OF OPERATION

(INTEGRATED IGNITION CONTROL)

Refer to Timing Charts for sequencing.

POWER UP

1. 115 VAC power applied to furnace.

2. Integrated ignition control performs internal checks.

3. Integrated ignition LED will light.

4. Integrated ignition control monitors safety circuits

continuously.

5. Furnace awaits call from thermostat.