<%).'&'M(+8dbWdAVi]Z$B^aa

"'."

I]Z XVgg^V\Z ]Vh adc\^ijY^cVa VcY Xgdhh ha^YZ

edlZg [ZZY XVeVW^a^i^Zh# 6aa Y^gZXi^dch gZkZghZ

l]Zche^cYaZgdiVi^dc^hgZkZghZY#

To set and engage the power feed:

1. 9>H8DCC:8I I=: A6I=:$B>AA ;GDB

EDL:G

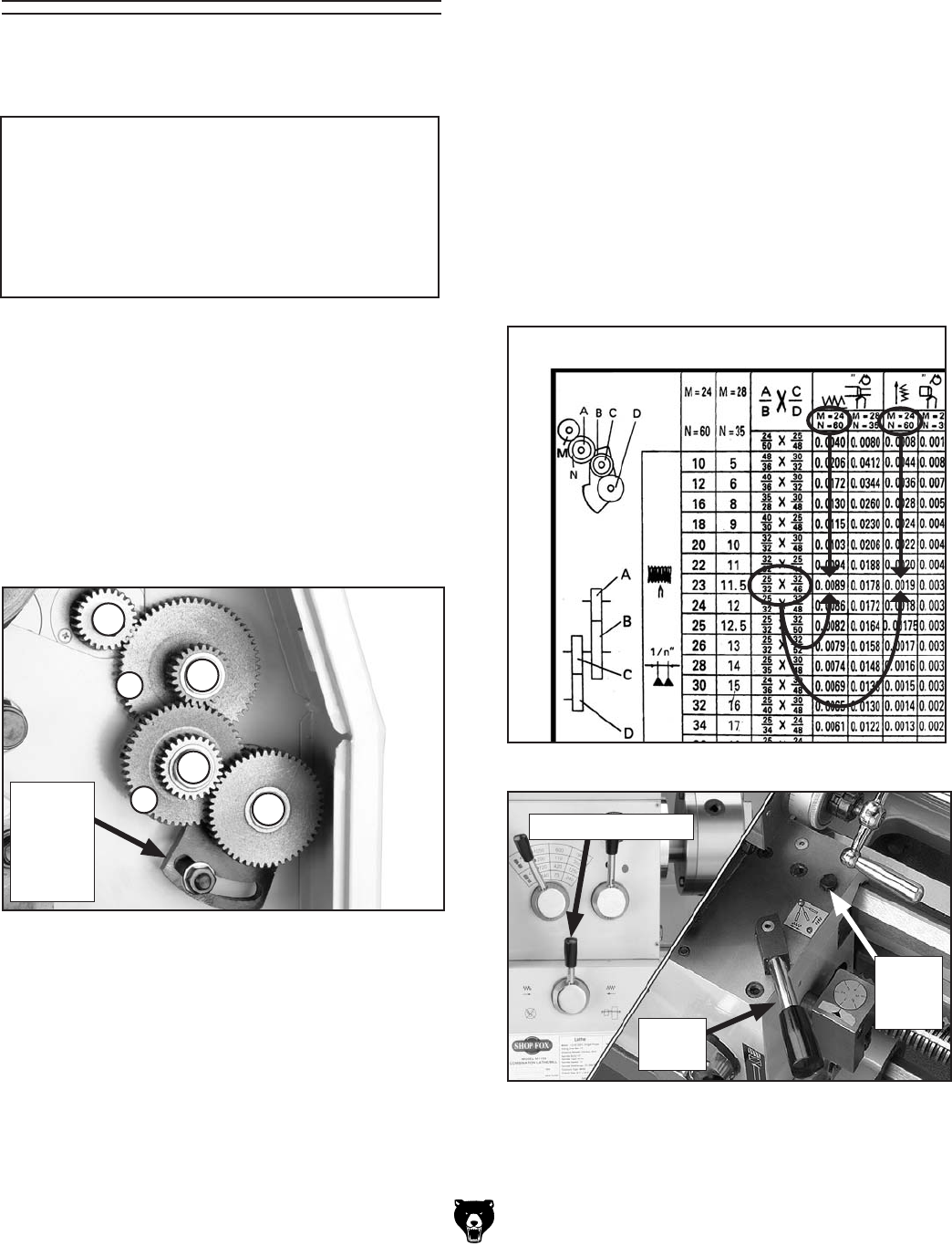

2. GZ[Zg id i]ZChange Gear Chart dc Page

31id YZiZgb^cZi]ZcZZYZY XdbW^cVi^dcd[

\ZVgh VcY l]^X] he^cYaZ adXVi^dc id ^chiVaa

ZVX] \ZVg dc# HZZ Figure 33 [dg i]Z \ZVg

^chiVaaVi^dc adXVi^dch i]Vi VgZ gZ[ZgZcXZYWn

i]ZX]Vgi#

3. HZZFigure 34 [dgVcZmVbeaZd[\ZVgXdb"

W^cVi^dchi]Vi\^kZi]Zadc\^ijY^cVaVcYXgdhh

ha^YZ gViZh# ;dg ZmVbeaZ/ I]Z X]Vgi h]dlh

i]Vi%#%%-.d[adc\^ijY^cVaigVkZaeZggZkdaj"

i^dc d[aZVYhXgZl ^hcZZYZY! dg%#%%&. d[

Xgdhh igVkZa eZg gZkdaji^dc d[ aZVY hXgZl ^h

cZZYZY#

Note:All change gears are stamped with the

number of teeth they have.

Figure 35.AZVYhXgZlVcY[ZZYaZkZgh#

Figure 33.8]Vc\Z\ZVgadXVi^dch#

9

8

6

7

C

B

Adc\^ijY^cVa

;ZZY

8gdhh

;ZZY

>cX]

I]gZVY^c\

AVh]

6Y_jhiZg

VcY

AdX`

Cji

NOTICE

Feed rate is based on spindle RPM. Pay

close attention to the feed rate you have

chosen and be ready to disengage the

apron. Failure to do this may cause the

carriage to crash into the chuck.

Figure 34.Jh^c\i]ZX]Vc\Z\ZVgX]Vgi#

;ZZY

AZkZg

AZVYhXgZlAZkZg

6egdc

AdX`

7dai

Setting Power Feed

Rate

4. AddhZc i]Z aVh] VY_jhiZg Figure 33 VcY

hl^c\i]ZVhhZbWandjid[i]ZlVn#

5. GZbdkZi]Z gZfj^gZY:"Xa^eh!ajWg^XViZ! VcY

hlVedjii]ZVeegdeg^ViZX]Vc\Z\ZVgh#

6. BdkZi]ZaVh]VY_jhiZghdi]Z\ZVgWVX`aVh]

^h Vi %#%%( id %#%%-! VcYi^\]iZc i]Z adX`

cji#

7. JhZi]ZaZVYhXgZlaZkZgidhZaZXiaZVYhXgZl

gdiVi^dcY^gZXi^dcFigure 35#

8. AddhZci]ZVegdcadX`Wdai!VcYjhZi]Z[ZZY

aZkZgFigure 35idZc\V\Zi]ZXgdhhha^YZdg

adc\^ijY^cVa[ZZY#