<%).'&'M(+8dbWdAVi]Z$B^aa

"(*"

To determine and set the mill to the needed

cutting RPM:

1. HZaZXi i]Z Xjii^c\ heZZY gZfj^gZY [dg i]Z

bViZg^Vad[ndjgldg`e^ZXZjh^c\i]ZiVWaZ^c

Figure 46#

NOTICE

Failure to follow RPM and Feed Rate

Guidelines will shorten cutter life and give

poor workpiece results and may threaten

operator safety from ejected parts or broken

tools.

Setting the Spindle

RPM

Never shift gears while lathe or mill is

running; otherwise, the gear teeth will be

chipped or broken.

NOTICE

Note:You will only be able to get an approxi-

mate RPM value with the variable speed

knob.

4. BdkZi]Zb^aa\ZVgWdmaZkZghidi]ZcZVgZhi

b^aa^c\heZZYGEB#

Cutting Speeds for High Speed Steel

(HSS) cutting tools:

Ldg`e^ZXZBViZg^Va 8jii^c\HeZZYh[b

6ajb^cjbVaadnh (%%

7gVhh7gdcoZ &*%

8deeZg &%%

8Vhi>gdc!hd[i -%

8Vhi>gdc!]VgY *%

B^aYHiZZa .%

8VhiHiZZa -%

6aadnHiZZa!]VgY )%

IddaHiZZa *%

HiV^caZhhHiZZa +%

I^iVc^jb *%

EaVhi^Xh (%%"-%%

LddY (%%"*%%

Figure 46.=^\]heZZYhiZZaXjii^c\X]Vgi#

Note: Double the cutting speed for car-

bide cutting tools. These values are a

guideline only. Refer to the MACHINERY'S

HANDBOOK for more detailed information.

2. BZVhjgZi]ZY^VbZiZgd[ndjgXjii^c\idda^c

^cX]Zh#

3. JhZ i]Z [daadl^c\ [dgbjaV id YZiZgb^cZ i]Z

cZZYZYGEB[dgndjgdeZgVi^dc/

(Cutting Speed x 4) / Tool Diameter = RPM

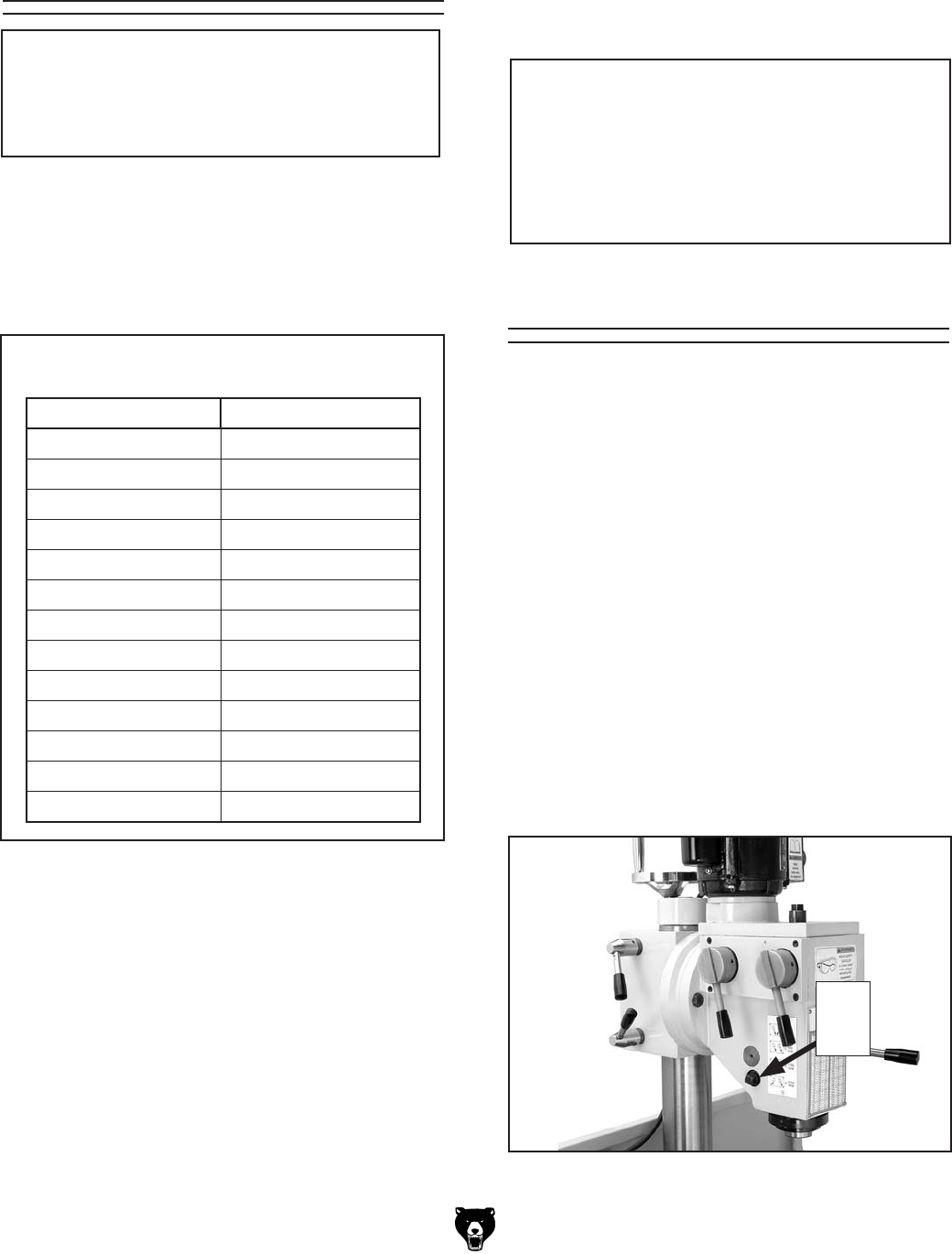

I]Zfj^aa[ZZY^hXdcigdaaZYWni]Z]VcYaZdci]Z

g^\]id[i]Z]ZVYhidX`!VcYVadX`Wdaidci]ZaZ[i

h^YZd[i]Z]ZVYhidX`Figure 47#

To use the quill:

1. =daYV[ZZY]VcYaZ!VcYaddhZci]Zfj^aa[ZZY

adX`WdaiidgZaZVhZi]Zfj^aa#

2. ;dgYg^aa^c\!ejaai]Z]VcYaZidlVgYndjVcYi]Z

fj^aal^aa[ZZYYdlcidlVgYi]Zldg`e^ZXZ#

Note: The quill feed handle is spring loaded.

DO NOT let go of the handle at the end of

a drilling operation or the quill will quickly

retract and slam into the headstock.

3. ;dgb^aa^c\!]daYi]Zfj^aaViVeVgi^XjaVgYZei]

VcYi^\]iZci]Zfj^aaadX`Wdai#

Figure 47.Fj^aaadX`#

Fj^aa

AdX`

7dai

Using the Mill