H8067 Flat Iron Style Mandolin Kit

-15-

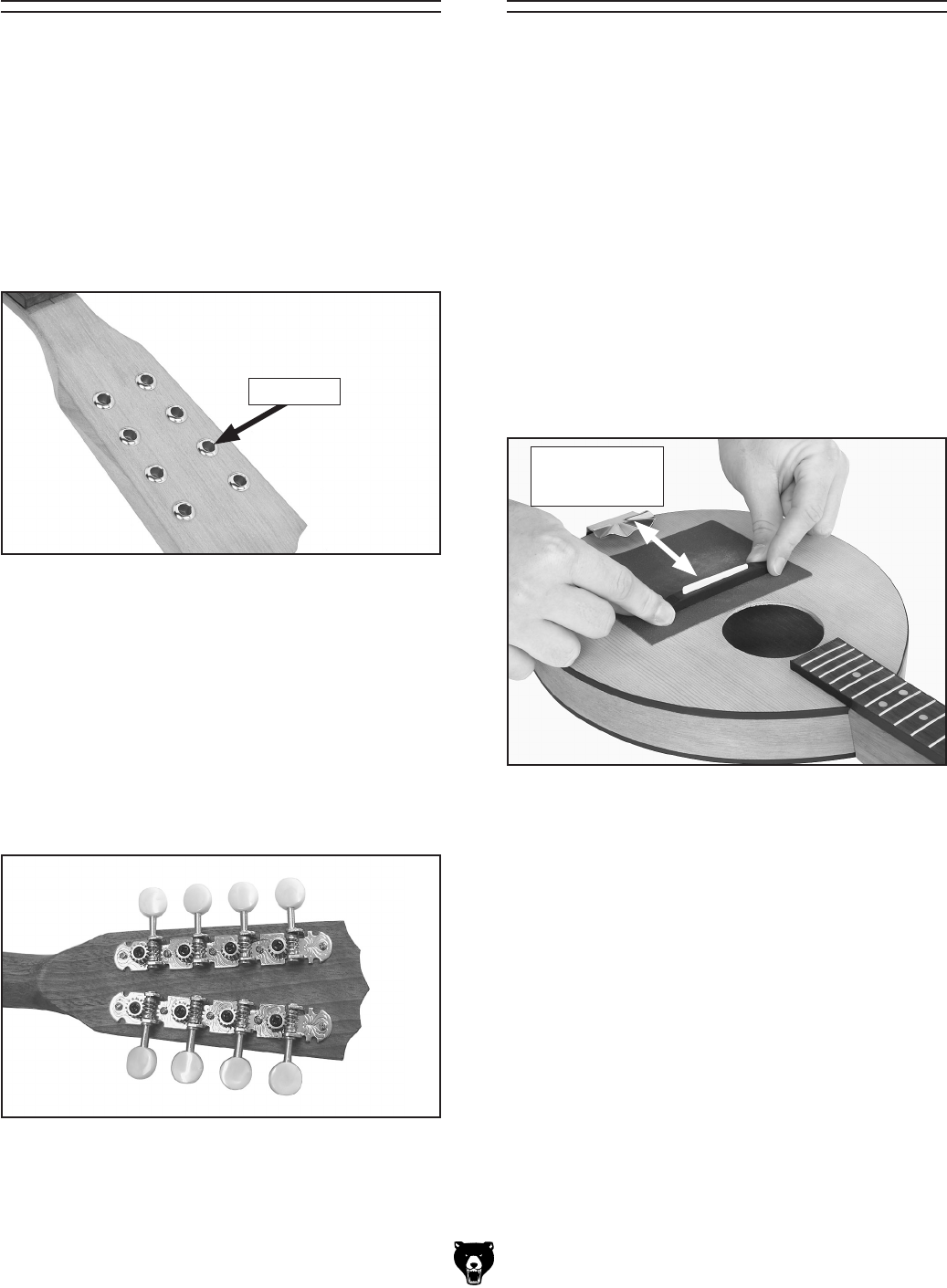

Figure 24. Peghead bushings.

Figure 25. Tuning machines installed

in the peghead.

Figure 26. Fitting the bridge to the soundboard.

2. Use a rubber dead blow hammer or a wood

block to seat the bushings so the bushing

flanges are flush with the peghead surface.

3. Turn the mandolin over and insert the tuning

machines into the back of the pegholes.

4. Attach both tuning machines to the peghead

with the #1 x

3

/8" screws (Figure 25).

2. Hold the sandpaper firmly (to avoid marring

the finish), and move the bridge back and

forth between the sound hole and the tail

-

piece.

3. Remove the sandpaper and place the bridge

on the soundboard. Look for gaps between

the bridge and the soundboard. Repeat Step

2 until there are no gaps.

Tuning Machines

Components and Hardware Needed: Qty

Mandolin Body ...................................................

1

Bridge ................................................................

1

This mandolin has a scale of 350mm, which

means that the bridge will be placed 350mm

(13.8") from the nut. Mandolin bridges are not

glued into place, but are held in place with the

string pressure, so final placement of the bridge

occurs when the strings are tuned.

To fit the bridge to the soundboard:

1. Place the bridge on a piece of sandpaper,

grit side up, 350mm from the nut as shown in

FIgure

26.

Fitting Bridge

Components and Hardware Needed: Qty

Mandolin Body ...................................................

1

Tuning Machines ...............................................

2

Bushings ............................................................

8

#1 x

3

/8" Stainless Steel Screws ...................... 10

To install the tuning machines:

1. Place the eight bushings in the pegholes as

shown in Figure 24

.

Bushing

Direction of

Sanding