701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

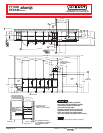

Page 2 of 12 F40352 – FT1000 Flight-Type Dishwasher

DESIGN: Fully automatic, ight-type dish machine

consisting of a load section with Automatic Soil

Removal system, power recirculating prewash, power

wash, power rinse and dual rinse/nal rinse section.

Included with each machine will be exible plastic

strip curtains to control overspray.

CONSTRUCTION: Stainless steel tank and chambers

with No. 3 polish on appearance surfaces. Frame,

legs and feet to be constructed of stainless steel.

Inspection doors to be chamber width.

PUMPS: Recirculating stainless steel pumps with

stainless steel impellers. Pump housing has easy

to remove coverplate for access to impeller. Wash

pumps are self-draining.

MOTORS: Totally enclosed fan cooled (TEFC) design

with overload protection. Pump motors to be 3

1

⁄2

H.P. for prewash, 5 H.P. for power wash and power

rinse, and conveyor motor to be

1

⁄3 H.P. Available in

electrical specications of 208/60/3, 240/60/3 and

480/60/3.

CONTROLS: A stainless steel control center with

electronic digital controls mounted at eye level.

Power “On/Off” and “Start/Stop” switches integrated

into keypad. Digital display indicates door(s) open,

low temperature alert, tanks/nal rinse temperatures,

Auto Clean and Auto Delime instructions and notica-

tions, and other pertinent operating data. Additional

“Start/Stop” switches are located at each end of

machine. Conveyor speed button included on the

control center to provide for the adjustable speed

conveyor.

FLIGHT-TYPE CONVEYOR: Stainless steel side

links, tie rods and conveyor tracks. Injection molded,

resilient Duraex ight links.

VENT: Single exhaust location.

AUTOMATIC SOIL REMOVAL SYSTEM (ASR):

Two foot section with specialized soil removal wash

arms which removes food soil from the ware before it

reaches the prewash tank. System will pump food soil

from the ASR tank into an external collector located

under the load section, minimizing the need to

pre-scrap dishes and reducing detergent consump-

tion. Operator can easily remove and clean external

collector without interruption of machine operation.

RECIRCULATING PREWASH SECTION: Prewash

compartment is tted with upper and lower wash

arms. Large removable one piece perforated stainless

steel screen sloped downward to deep stainless steel

scrap basket.

TANK HEAT: Power wash, power rinse and dual

rinse tank water temperatures are thermostatically

controlled. Low water protection is provided. Specify

either electric or steam heat.

FINAL RINSE: Easily removed nal rinse arms.

VENTLESS ENERGY RECOVERY SYSTEM: Energy

Recovery system operates with a cold water line,

capturing energy from exhaust air, and using it to

elevate the temperature of the cold water. The result

is savings – both in hot water and in energy.

Machine to be equipped with Ventless technology

– an integrated heat pump that will capture the heat

from the waste air and use the recycled energy to

heat the machine’s wash tank, blower dryer and nal

rinse.

CONVEYOR DRIVE UNIT: Powered by a

1

⁄3 H.P.

motor. Trip mechanism provided on unload section.

Jam protection is provided by load sensing switch

at drive platform. Conveyor speed adjustment of 4.0

feet per minute to 8.5 feet per minute is provided on

the digital display keypad.

DRAINS: Manual, hand-operated, located at each

tank. One manual and automatic master drain to be

used for Auto Clean and Auto Delime.

BLOWER DRYER: Blower dryer is heated by the heat

pump system. Includes (2) 2 H.P. fan motors with

sealed ball bearings and overload protection.

FT1000

FLIGHT-TYPE DISHWASHER