701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

F40352 – FT1000 Flight-Type Dishwasher Page 3 of 12

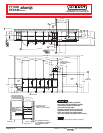

FT1000

FLIGHT-TYPE DISHWASHER

Variable speed

conveyor offers

increased

throughput.

The conveyor

on the FT1000

Series is wider

so it can handle

more ware.

Result: more volume and versatility, quicker work. Its

speed is easily adjustable for the type of ware, soiled

condition, or workforce requirements. It runs at 4.0 -

8.5 feet per minute.

Advansys systems provide

lowest cost of ownership.

The Energy Recovery

system captures escaping

heat and steam from the

exhaust air and uses it to

preheat the incoming cold

water supply before it enters

the booster heater. The

industry’s only ight-type

ventless system features

heat pump technology, capturing the remaining heat

that passes through the energy recovery system and

uses it to heat the wash tank, blower dryer and nal

rinse, while eliminating the need for a vent hood.

Self-draining wash pumps help keep water clean.

Pumps are self-draining when the machine is shut

down, so there is no residual water left in the pumps.

Installation is quick and easy with modular design

and minimal wiring connections.

Modular design means

the FT1000 installs quickly

and reliably. The control

panel is already in place,

premounted to the dual

rinse/nal rinse section.

Wiring connections are

minimal, saving time and

expense. The control box

uses a “single plane”

circuitry design for easy

accessibility during

installation and service.

The FT1000 is ready to

run quickly.

No other control

system allows

easier monitoring.

The digital controls are

placed in a convenient

panel that lets operators verify proper operation and

temperatures at a glance. Digital display indicates

the unit is on, and conrms that the doors are

closed. Automatic door interlocks prevent the pump

and conveyor from operating if the doors are open.

Easy-to-read digital display indicates accurate

temperatures of the 150°F wash, 160°F power rinse,

160°F dual rinse and 180°F nal rinse — critical for

proper HACCP system record-keeping.

Stainless steel pump is built for long life.

The stainless steel pump housing and impeller offer

greater durability and long life. The pump motor is

totally enclosed and fan cooled (TEFC) to protect it

from water spray during dishroom clean-up.

Scrap baskets

capture food particles

and are easy to clean.

The sloped screens that

carry scraps to the scrap

baskets are steeper, so less

soil gets into the tanks. The basket

opening is larger for easy cleaning and basket

handles have been designed for easy lift-out access.

The load section also features a removable scrap

basket which contains soil that is pumped from the

ASR section. All scrap baskets and strainers are

stainless steel for strength and durability.

The FT1000

Series saves

water and

energy.

The unit has the

lowest water

and energy

consumption in

the industry, yet

provides effective cleaning and sanitizing that meets

NSF International requirements.

This is achieved through

a carefully balanced ratio

of water ow to pressure.

Insulated doors and thermal

layered curtains also reduce

heat loss. The unit’s 58

gallons per hour rinse ow

rate saves both water and the

energy to heat it.