701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

F40352 – FT1000 Flight-Type Dishwasher Page 7 of 12

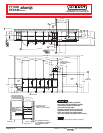

FT1000

ELECTRIC R-L

SERVICE CONNECTION WITH CIRCUIT BREAKERS

(2) SERVICE CONNECTIONS AS SHOWN BELOW

MOTORS,CONTROLS,POWER RINSE & BOOSTER HEAT (TB1)

(1) SERVICE CONNECTION AS SHOWN BELOW

ELEC.

SPECS.

RATED

AMPS

MINIMUM

SUPPLY

CONDUCTOR

AMPACITY

MAXIMUM

PROTECTIVE

DEVICES

208/60/3

200 200

240/60/3

200

200

480/60/3

100 100

152.0

147.2

82.0

B/D BLOWERS, WASH TANK AUX HEAT, DUAL RINSE HEAT

& HEAT PUMP COMPRESSOR (TB2)

(1) SERVICE CONNECTION AS SHOWN BELOW

ELEC.

SPECS.

RATED

AMPS

MINIMUM

SUPPLY

CONDUCTOR

AMPACITY

MAXIMUM

PROTECTIVE

DEVICE

208/60/3

109.9

150 150

240/60/3

106.3

150 150

480/60/3

52.6

70 70

SERVICE CONNECTION W/O CIRCUIT BREAKERS

(5) SERVICE CONNECTIONS AS SHOWN BELOW

ELECTRIC TANK HEAT, DUAL RINSE (13KW), B/D BLOWERS

(1) SERVICE CONNECTION AS SHOWN BELOW

ELEC.

SPECS.

RATED

AMPS

MINIMUM

SUPPLY

CONDUCTOR

AMPACITY

MAXIMUM

PROTECTIVE

DEVICES

208/60/3

60 60

240/60/3

60 60

480/60/3

30 30

45.7

43.9

22.6

ELECTRIC TANK HEAT, POWER RINSE

(1) 26 KW CONNECTION AS SHOWN BELOW

ELEC.

SPECS.

RATED

AMPS

208/60/3

77.8

100 100

240/60/3

74.2 100 100

480/60/3

37.06

06

0

MINIMUM

SUPPLY

CONDUCTOR

AMPACITY

MAXIMUM

PROTECTIVE

DEVICES

ELEC.

SPECS.

RATED

AMPS

MINIMUM

SUPPLY

CONDUCTOR

AMPACITY

MAXIMUM

PROTECTIVE

DEVICES

208/60/3

64.2 80 80

240/60/3

62.4 80 80

480/60/3

30.0 40 40

HEAT PUMP COMPRESSOR & WASH TANK AUX HEAT (13 KW)

(1) CONNECTION AS SHOWN BELOW

ELEC.

SPECS.

RATED

AMPS

MINIMUM

SUPPLY

CONDUCTOR

AMPACITY

MAXIMUM

PROTECTIVE

DEVICES

208/60/3

27.0 35 35

240/60/3

25.8 35 35

480/60/3

12.9 20 20

ELECTRIC BOOSTER

(1) 9 KW CONNECTION AS SHOWN BELOW

Electrical and grounding connections

must comply with the applicable portions

of the National Electrical Code and/or

other local electrical codes.

Plumbing connections must comply with

applicable sanitar

y, safety and plumbing

codes.

Drain and fill line configurations

vary, some methods are shown on this drawing.

Pressure gauge not required on pumped rinse machines.

GENERAL NOTES:

(a)

THE CONTROL BOX IS ATTACHED TO THE CENTER SECTION AND IS

ROTATED 90 DEGREES FOR SHIPPING.

AFF = ABOVE FINISHED FLOOR

A

LL DIMENSIONS TAKEN FROM THE FLOOR LINE MAY INCREASE 3-1/4" WITH

LEG ADJUSTMENT.

FOR CONVENIENCE WHEN CLEANING, CUSTOMER SHOULD INSTALL WATER

T

AP NEAR MACHINE WITH 30 FT. OF HEAVY DUTY HOSE WITH SQUEEZE VALVE.

THIS DRAWING IS SUPPLIED AS A REFERENCE FOR CONNECTION INFORMATION

ONLY. IT WILL NOT BE UTILIZED FOR MANUFACTURING OF UNIT.

ELECTRICAL WARNING:

SERVICE WIRE TEMPERATURE RATING: 90C.

PLUMBING NOTES:

RECOMMENDED WATER HARDNESS TO BE 3 GRAINS OR LESS PER

G

ALLON FOR BEST RESULTS.

(b)

RECOMMENDED BUILDING FLOWING HOT WATER PRESSURE TO THE

DISHWASHER IS 40-45 PSI.

(c)

RECOMMENDED BUILDING FLOWING COLD WATER PRESSURE TO

THE DISHWASHER IS 30-35 PSI. IF COLD WATER IS LESS T

HAN 55°F

CONTACT SALES ENGINEERING.

(d)

WATER HAMMER ARRESTOR (MEETING ASSE-1010 STANDARD OR

EQUIVALENT) TO BE SUPPLIED (BY OTHERS) IN HOT AND COLD

WATER SUPPLY LINES AT SERVICE CONNECTION.

VENTILATION NOTES:

(e) THE VENT STACK AND ITS ENCLOSURE CAN BE TEMPORARILY REMO

VED FROM

THE ENERGY RECOVERY UNIT TO YIELD 81-7/8" CLEARANCE FOR DOORWAYS.

ELECTRICAL CONNECTIONS

COMMON ON

ALL MODELS:

E1

ELECTRIC CONNECTION, DETERGENT AND RINSE FEEDER

S

(MACHINE SERVICE VOLTAGE), 1/2" CONDUIT.

79-1/8" AFF

E2 ELECTRIC CONNECTION

, VENT FAN CONTROL.

(SWITCH CONTACTS) 1/2" CONDUIT. 79-1/8" AFF

ELECTRICAL CONNECTIONS

W/O CIRCUIT BREAKERS:

E3

ELECTRIC CONNECTION, MOTORS & CONTROLS,

1" CONDUIT. 79-1/8" AFF

E4

ELECTRIC TANK HEAT CONNECTION, POWER RINSE TANK, 26KW.

1-1/4" CONDUIT. 79-1/8" AFF

E5

ELECTRIC TANK HEAT CONNECTION, WASH TANK AUX HEAT, 13K

W.

HEAT PUMP COMPRESSOR.

1" CONDUIT. 79-1/8" AFF

E6

ELECTRIC TANK HEAT CONNECTION, DUAL RINSE TANK, 13KW.

B

LOWER DRYER BLOWERS.

1" CONDUIT. 79-1/8" AFF

E7

ELECTRIC CONNECTION, BOOSTER, 9KW.

1" CONDUIT. 79-1/8" AFF

ELECTRICAL CONNECTIONS

WITH CIRCUIT BREAKERS:

E8 ELECTRIC CONNECTION, MOTORS, CONTROLS, POWER RINSE &

BOOSTER HEAT (WHEN CIRCUIT BREAKER OPTION IS SPECIFIED)

.

(TB1) 2" CONDUIT, 79-1/8" AFF

E9 ELECTRIC CONNECTION, B/D BLOWERS, WASH TANK AUX HEAT,

DUAL RINSE HEAT & HEAT PUMP COMPRESSOR (TB2).

2" CONDUIT, 79-1/8" AFF

MODEL:

FT1000

ADVANSYS

ELECTRIC

R-L OPERATIO

N

00-949508

REV A1

VENTILATION REQUIREMENTS:

V1 IF SUPPLEMENTAL VENTILATION IS REQUIRED TO HANDLE MACHINE’S

LATENT & SENSIBLE HEAT:

MINIMUM OF 24" SQUARE VENT HOOD WITH 6 INCH AIR GAP CAPABLE OF

PROVIDING 750 CFM EXHAUST AT STANDARD AIR CONDITIONS (VENT HOOD

SUPPLIED AND INSTALLED BY OTHERS). WHEN VENT HOOD IS INSTALLED,

BACK DRAFT PREVENTER IS REQUIRED (SUPPLIED AND INSTALLED BY OT

HERS).

95-3/8" AFF

PLUMBING CONNECTIONS:

P1 COMMON HOT WATER CONNECTION (AUTOMATIC FILL) 110°F WATE

R

MINIMUM, 1" FPT, 5-1/2" AFF see notes (b) AND (d).

P2 COMMON COLD WATER CONNECTION, 55°F WATER MINIMUM,

1" FPT, 5-1/2" AFF see notes (c) AND (d).

P3 COMMON DRAIN CONNECTION.

TWO CONNECTION LOCATIONS; MAY BE DRAINED TO EITHER END

OF UNIT, PLUG OPPOSITE END.

2" FPT. 7" AFF

MOTORS AND CONTROLS

(1) SERVICE CONNECTION AS SHOWN BELOW

ELEC.

SPECS.

RATED

AMPS

MINIMUM

SUPPLY

CONDUCTOR

AMPACITY

MAXIMUM

PROTECTIVE

DEVICE

208-240/60/3

47.2

60 60

480/60/3

32.1

40 40