23

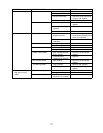

3. Faulty Dispenser

PROBLEM POSSIBLE CAUSE REMEDY

[1] a) 1. Ice block or bridge. 1. Remove all ice from storage

bin when not using ice

dispenser for a long time.

2. Incorrect wiring. 2. Correct wiring.

b) Agitator 1. Deformed due to ice

block or bridge.

1. Replace.

c) Solenoid 1. Coil winding opened. 1. Replace.

d) Ice switch or dispensing

sensor.

1. Bad contacts. 1. Check for continuity and

replace.

e) Ice Dispensing Relay 1. Bad contacts. 1. Check for continuity and

replace.

[2] a) Water Valve

(Dispensing)

1. Clogged filter. 1. Clean.

b) Water Dispensing

Sensor

1. Bad circuit. 1. Check for continuity and

replace.

[3] Ice keeps being

dispensed.

a) Shutter 1. Faulty adjustment. 1. With shutter closed, lock

shutter in place by securing

with two screws at the lower

part of the solenoid and two

screws under solenoid.

b) Ice Switch

Dispensing Switch

1. Contacts fused. 1. Replace.

Storage BinNo ice is dispensed.

No water is dispensed.

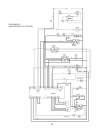

[a] Optical Sensor Description

This model incorporates touch-free optical sensors to control ice and water dispensing. The

sensors operate by using an emitter and two receivers encased in a waterproof sensor

housing. They are designed to operate in normal lighting conditions. Direct sunlight,

however, may cause the sensors to malfunction. The sensors will work with most shades

(colors) of cups with a sensing distance of 45 to 65 mm. In certain water conditions, the

lenses of the sensor may become scaled. Scale can block the sensor and affect the sensing

operation. This scale can be removed by using a solution of Scale Away (6 fl. oz per 1 gal.

of water) or other non-abrasive cleaner.

This DCM uses a different control board (part number 2A2867-01) than the push button style

of DCM. This board provides an internal power source for the sensing circuit and has an

additional connector (K5). This board is not interchangeable with the control board used on

the push button version. When troubleshooting the sensor operation, we will be concerned

with the K5 and K2 connectors on the control board. The K2 connector will supply line

voltage (115VAC) to the ice dispensing motor and ice dispensing solenoid and 24VAC to

the water dispense solenoid. The K5 connector provides the input and output from the

sensors.

These sensors control water dispense and ice dispense in both the portion and continuous

dispense operation. The ice dispense time is limited to 60 seconds regardless of whether

the customer is using the “Continuous” or the “Portion Control” function. This non-

adjustable, maximum timer prevents continuous dispense if someone inadvertently leaves

an object in front of the dispense sensor.