21

m) Overfreeze Detection Control (S2 dip switch 5) [Program Ver. 3.2]

Do not adjust. This must be left in the factory default position or the unit will not operate

properly.

It is deactivated on the KM-201BAH/BWH and KM-260BAH/BWH.

When activated, the thermistor detects the temperature of the evaporator outlet to fi nd

overfreeze in a harvest cycle and at the beginning of a freeze cycle. If the difference

between the maximum temperature after the water saver timer starts counting and the

temperature at the end of a harvest cycle is 4K or more and if the temperature at the end

of a harvest cycle is 48°F (9°C) or less, the harvest cycle is extended for 30 seconds.

If the difference between the temperature at the beginning of a freeze cycle and the

minimum temperature after 30 seconds in the freeze cycle is 2.5K or more and less than

3.5K, the next harvest cycle is extended for 30 seconds. If the above conditions occur

in succession, the number of occurrence times 30 seconds will be added to the harvest

cycle time. If the above temperature difference is 3.5K or more, the freeze cycle ends

after the minimum freeze cycle time and a harvest cycle starts.

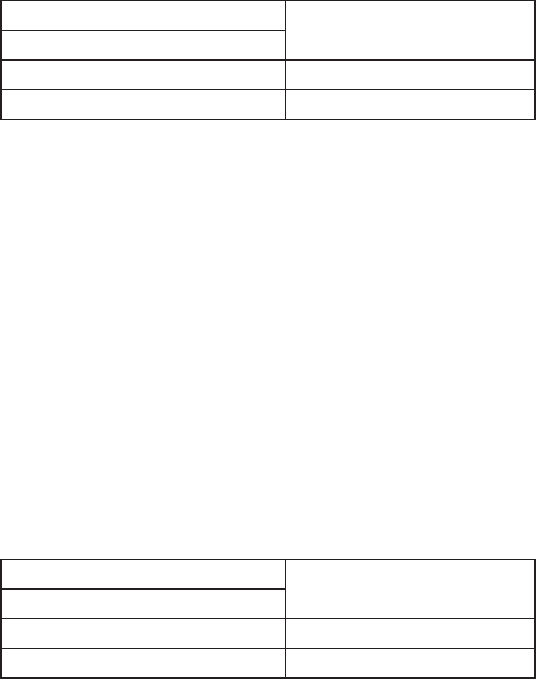

S2 Dip Switch Setting

Overfreeze Detection

Control

No. 5

OFF Deactivated

ON Activated

n) Anti-Slush Control (S2 dip switch 6) [Program Ver. 3.2]

Do not adjust. This must be left in the factory default position or the unit will not operate

properly.

When activated (Ver. 1.1), the thermistor located on the suction line checks for a 41°F

(5°C) temperature as the evaporator cools. When 41°F (5°C) is reached, a 4.8 k signal

causes the control board to de-energize the pump motor for 10 seconds.

When activated (Ver. 2.0), the thermistor located on the suction line checks for a 50°F

(10°C) temperature as the evaporator cools. When 50°F (10°C) is reached, a 3.9 k

signal causes the control board to de-energize the pump motor for 10 seconds and

energize it for 50 seconds repeatedly. When 34°F (1°C) is reached, a 5.9 k signal

causes the control board to de-energize the pump motor for 10 seconds, energize it for

50 seconds, de-energize it again for 10 seconds, then energize it continuously.

S2 Dip Switch Setting

Anti-Slush Control

No. 6

OFF Activated (Ver. 1.1)

ON Activated (Ver. 2.0)

[d] CONTROL BOARD CHECK PROCEDURE

Before replacing a control board that does not show a visible defect and that you

suspect is bad, always conduct the following check procedure. This procedure will help

you verify your diagnosis.