How It Works ICEU060

Page 10

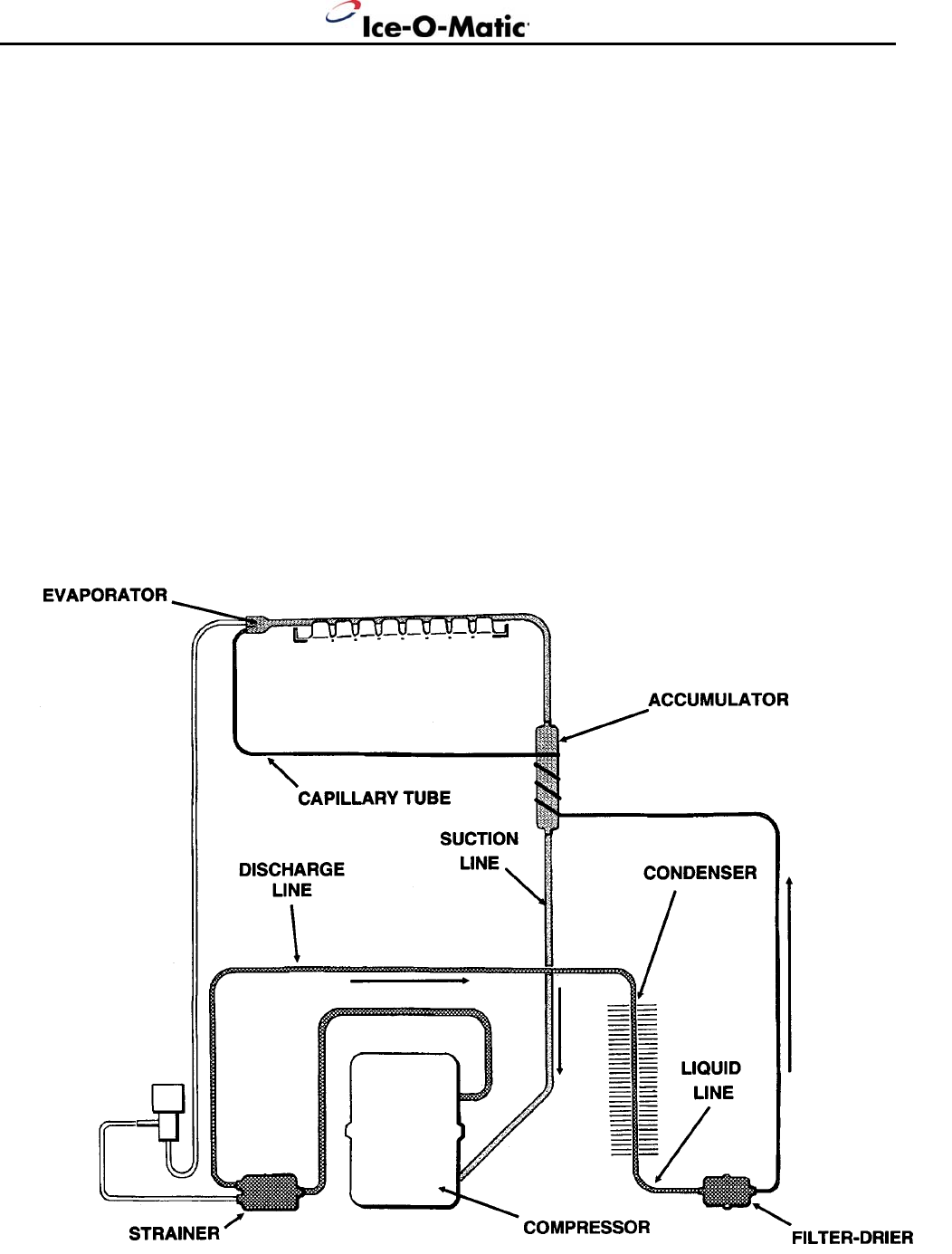

Refrigeration System

Freezing Cycle

The ice cubes are formed in an inverted mold that is refrigerated.

The refrigeration process begins at the compressor. There, refrigerant vapor is compressed and flows

from the compressor through the discharge line as a high temperature, high pressure gas. In the

discharge line there is a strainer with two outlets; one leads to the condenser, and the other one to the hot

gas valve. Because the hot gas solenoid is closed, the gas flows to the condenser, where heat is

transferred from the refrigerant to the air passing through the condenser. The refrigerant then condenses

into a high pressure liquid.

From the condenser, the liquid refrigerant flows through the liquid line, and the liquid line filter drier. After

the filter drier, the liquid refrigerant enters the metering device, a capillary tube. After passing the

restriction of the capillary tube, the refrigerant enters an area of relative low pressure, the evaporator. In

the tubing of the evaporator, the liquid refrigerant expands and evaporates, absorbing heat from the

evaporator tubing and anything in contact with it such as water sprayed against it.

The refrigerant, now a low pressure, low temperature vapor, flows into the accumulator, which traps

excess liquid refrigerant. The vapor, now primarily a gas, goes through the suction line and back to the

compressor.