16

630460150

GEARMOTOR

The gearmotor is equipped with a start relay and a manual reset overload.

When current is applied, the relay energizes and completes the circuit to the start winding. The motor reaches a

predetermined speed and the relay drops out, disconnecting the start winding. The run winding remains in the

circuit as long as current is applied.

The purpose of the overload is to automatically shut off the motor in the event of a mechanical bind of the trans-

mission, an overload condition within the evaporator or an electrical malfunction. It does this by sensing amper-

age draw. If the motor stalls the start relay would energize and stay energized. The amperage would surge 5 to

6 times greater than the normal draw. In this event the overload would shut off the transmission in 4 to 8 sec-

onds.

If the motor is subjected to an abnormal load, but does not reach a stall condition, the overload will react, but

over a greater period of time. The reaction time depends upon the amperage to which it is subjected.

The overload, through the safety circuit, also shuts off the compressor.

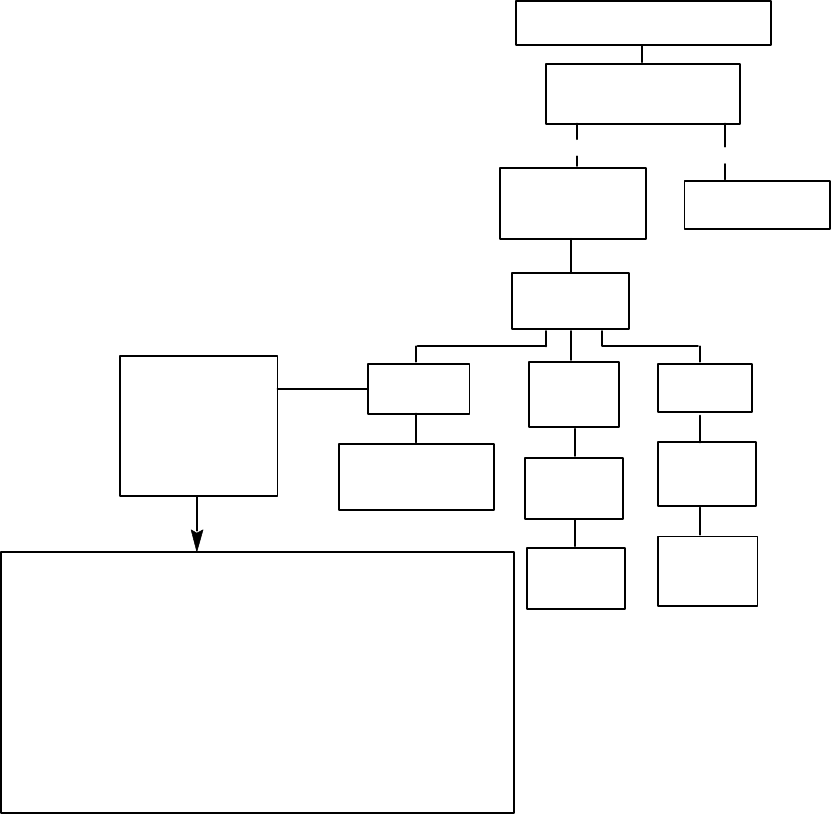

GEARMOTOR

OVERLOAD TRIPPED

Check water level control

and evaporator water tube

for line build-up restrictions.

Clear ice from

evaporator and

auger before

resetting overload.

CLEAN

CAUTION

See Instructions.

Overload

hot try

again.

YES

NO

Reset overload.

Resets but

motor does

not run.

Will not

Reset.

Icemaker

runs.

IMPORTANT

Will not

reset.

Replace

overload.

Resets but

motor does

not run.

Check

gearmotor

circuits.

Short run. Trips

again in 2

minutes. Check

gearmotor circuits.

Icemaker runs when

reset but problem has

not been found.

Continue checking for

overload as follows to

guard against future

problems.

OVERLOAD GUIDE

ELECTRICAL:

S High or low voltage. Weak power lines can cause overloads on icemakers restarts.

S High running current (2.4amps or above). Check motor circuits and start relay.

S Auger delay failed.

ICEMAKER

S Mechanical parts worn. Scored evaporator or auger. Worn thrust bearing.

S Icemaker not turning off. Failed ice level control.

S Over compression. Low water inlet temperature. Restrictions in water line from reservoir.

REFRIGERANT

S Contaminated charge or bad compressor.

S Low charge or gas leak.

S Low suction pressure. Improper expansion valve. Sensing bulb location or insulation

and/or defective expansion valve.

MOTOR CHECK

The resistance readings on the winding will be between 5 to 25 ohms. A meter capable of these low readings

must be used. The start relay cover must be removed. (See Figure 7).

If no continuity on start or run winding test, replace gearmotor. If continuity on grounded motor test, replace

gearmotor.