Important Installation Suggestions Pressure Testing

1. Chamfer all exposed edges of decorative laminateto The maximum gas supply pressure for the appliance

prevent damage from chipping, pressure regulator supplied on this appliance is 14" W.C.

2. Radius corners of cutout and file to insure smooth The test pressure for checking this appliance pressure

edges and prevent comer cracking, regulator must be at least 6" W.C. for Natural Gas, and at

least t 1" W.C. for LP. It is shipped from the factory set for

3. Rough edges, inside corners which have not been Natural Gas at 5" W.C.

rounded and forced fits can contribute to cracking of the

countertop laminate. This appliance and its individualshutoff valve must be

disconnected from the gas supply piping system during

4. Countertop must be supported within 3" of cutout, any pressure testing ofthat system attest pressures in

excess of 112"PSIG (3.5 k Pa).

On any burner, closing the air shutter too far will

cause the flame to become soft and yellow tipped. This appliance must be isolated from the gas supply

Opening the air shutter too wide will cause the flame piping system by closing its individual manual shutoff

to blow away from the burner ports. Proper adjustment valve during any pressure testing of the gas supply piping

will produce a sharp, clearly defined, even blue flame, system at test pressures equal to or less than 1/2" PSIG

(3.5 k Pa).

Low Flame Adjustment

(See Illustration "C") Appliance Pressure Regulator

This appliance isshippedfromthefactorywithlow and Conversion

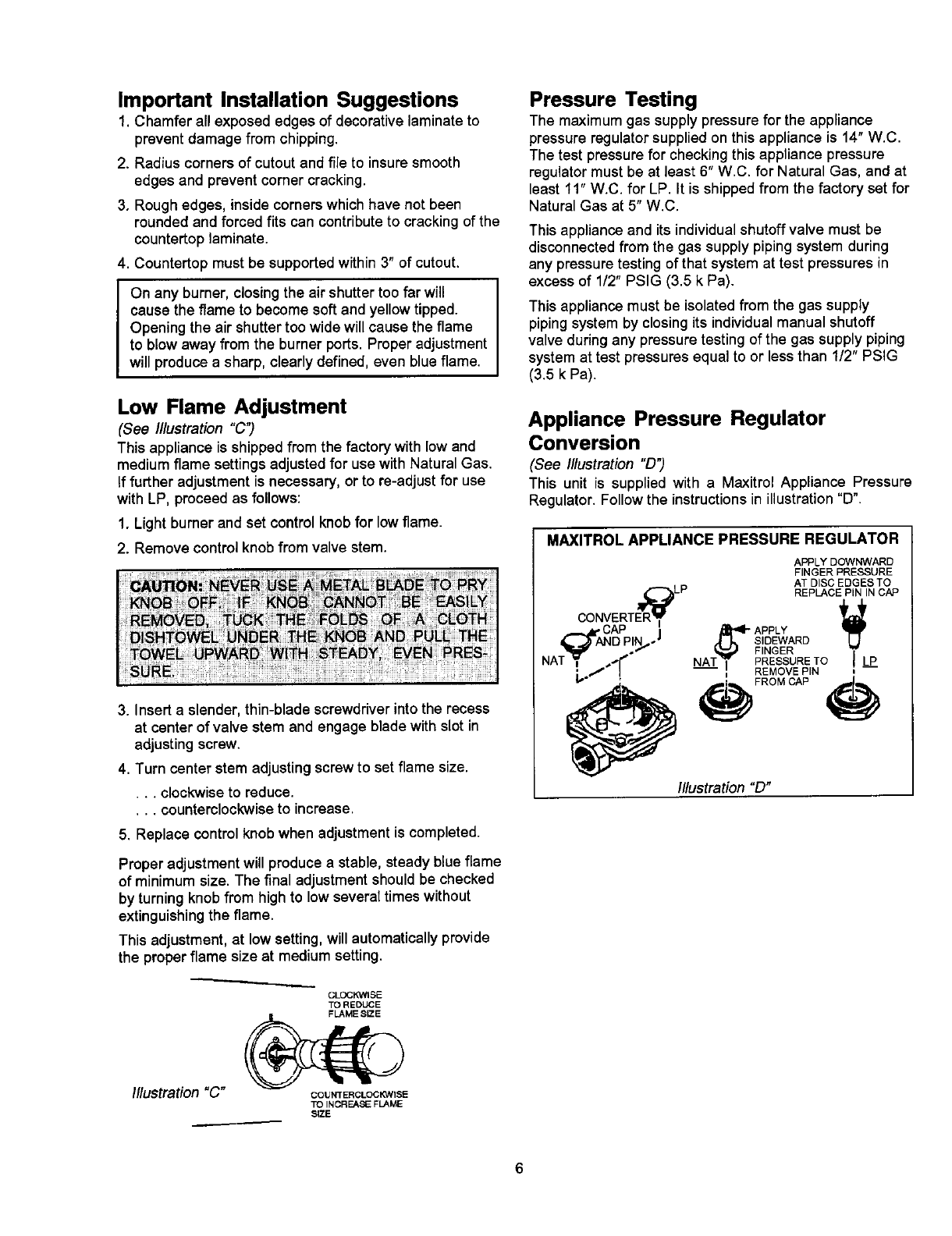

mediumflame settingsadjustedfor usewithNaturalGas. (See Illustration "D")

If furtheradjustmentisnecessary,orto re-adjustfor use This unit is suppliedwith a MaxitrolAppliance Pressure

withLP, proceedas follows: Regulator.Followtheinstructionsin illustration"D".

1. Lightburnerand set controlknobforlowflame.

2. Removecontrolknobfromvalvestem. MAXlTROL APPLIANCE PRESSURE REGULATOR

APPLYDOWNWARD

FINGERPRESSURE

ATDISCEDGESTO

ER_I LP REPLACEPININCAP

CONVERT

CAP I _ APPLY

AND PIN..,,,-". TI_ SIDEWARDFINGER

NAT _../.," r NA PRESSURETO !LP

, REMOVEPiN --

3. Insert a slender, thin-blade screwdriverintothe recess _ Ii_FROM CAP II_

at center of valve stem and engage blade with slot in

adjusting screw.

4. Turn center stem adjusting screwto set flamesize.

• . . clockwise to reduce. Illustration "D"

... counterclockwiseto increase.

5. Replacecontrol knobwhen adjustment is completed.

Proper adjustment willproduce a stable, steady blue flame

of minimum size. The final adjustment shouldbe checked

by turning knob from high to lowseveral times without

extinguishing the flame.

This adjustment, at lowsetting, will automatically provide

the proper flame size at medium setting.

CLOCKWISE

TOREDUCE

Illustration "C" colJwrERCLOCK'WISE

TO INCREASE FLAME

SIZE