- CARE OF YOUR REVERSE OSMOSIS SYSTEM -

TUBING CONNECTION

(all push- in fitting locations)

This RO system includes push-in fittings for quick

tubing connection at most locations. If working with

the fittings, do the following.

Connection (Figure 12):

1. Use a sharp cutter or knife to cut the end of tubing

square.

2. Inspect the end (about 1") of the tubing to be sure

there are no nicks, scratches or other rough spots. If

needed, cut the tubing again.

3. Push tubing through the collet and all the way into

fitting. Full engagement is 11/16" for 1/4" tubing,

and 3/4" for 3/8" tubing.

If using tubing other than tubing supplied with the

system, be sure it is of high quality, exact size and

roundness with a smooth surface.

Tubing correctly cut and connected

cut tubing s_uare

I I

I

end of tubing round and

smooth, with no cuts,

nicks or fiat spots

collet .__

_ 11/16" (1/4" tubing)

' engagement

Fg=- 3/4" (3/8" tubing)

Figure 12

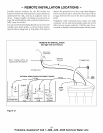

To Disconnect Tubing (Figure 13): Push the collet in-

ward and hold with a finger while pulling the tubing

out.

Changing Collet and O-ring (Figure 13):

1. With a small screwdriver remove the collet and o-

ring from the fitting. Be careful not to scratch the in-

ternal walls of the collet port.

2. Be sure the port is clean, then lubricate and insert

the o-ring seal to the bottom of the port.

3. Push the collet inward until it locks in place.

collet (depress to

remove tubing)

tubi_._

/

Replacing collet and

o-ring seal

Push o-ring seal into

bottom of port, then

follow with collet.

_--_fitting

collet

! m 1

I CAUTION I

I DO NOT USE VINEGAR OR OTHER ACID BASED I

I CLEANERS ON THIS RO SYSTEM. THEY WILL I

I DEGRADE SOME RO SYSTEM PARTS. ALWAYS I

I USE SOAP ANDWATER. I

I m m.I

I This reverse osmosis system contains a replaceable I

treatment component critical to the efficiency of the

I system. Replacement of the reverse osmosis compo- I

I nent should be with one of identical specifications, I

I as defined by the manufacturer; to assure the same I

I efficiency and contaminant reduction performance. I

I _ m.I

AUTOMATIC SHUTOFF SERVICE

If the shutoff assembly requires service, be sure to

reassemble parts exactly as shown in Figure 14.

screw (4)

SHUTOFF

ASSEMBLY

diaphragm

plunger

spacer ring

o-ring

spring

ball

check

valve

diaphragm

Figure 13 Figure 14

14

Problems, Questions? Call 1-800-426-9345 Kenmore Water Line