4

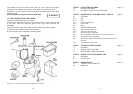

TABLE OF FIGURES

Fig. No 1 General view of the Vegetable Preparation Machine

model “XVP001”

Page 6

Fig. No 2 Position of the electrical safety protection Page 8

Fig. No 3 Position of the mechanical safety protection Page 8

Fig. No 3A Position of the electrical safety measures Page 8

Fig. No 4 Position of the chute or the bowl to allow the machine to

be started.

Page 9

Fig. No 5 Machine on-off control. Page 9

Fig. No 6 Small pusher for pushing vegetables down Page 10

Fig. No 7 Bowl with magnetic sensor Page 10

Fig. No 8 Chute to direct the food Page 10

Fig. No 9 Expulsion arm Page 11

Fig. No 10 Disc rack Page 11

Fig. No 11 Discs for slicing Page 11

Fig. No 12 Discs for julienne Page 12

Fig. No 13 Discs for dicing Page 12

Fig. No 14 Discs for grating Page 12

Fig. No 15 Dimensions and weights Page 13

Fig. No 16 Description of the packaging Page 14

Fig. No 17 Collecting bowl Page 15

Fig. No 18 Directing “chute" Page 16

Fig. No 19 Technical plate – registration Page 16

Fig. No 20 Diagram of the single phase electrical equipment Page 17

Fig. No 21 Start and stop button. Page 17

Fig. No 22 Fitting the expulsion arm Page 18

Fig. No 23 Fitting the dicing – slicing combination Page 18

Fig. No 24 Correct operating position Page 19

Fig. No 25 Food added using the large feed tube Page 19

Fig. No 26 Food added using the small feed tube Page 19

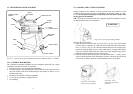

Fig. No 27 View of the machine dismantled for cleaning Page 22

21

6.2 - TROUBLESHOOTING

6.2.1 - The disc lock is defective:

Check that the discs and the disc-holding spindle are clean.

6.2.2 - The cover does not lock:

Check that the cover is correctly closed and that it is clean.

6.2.3 - The food is not cut properly:

Check the state of wear of the cutters.

6.2.4 - The cut food does not come out or is not properly cut:

Check that the expulsion arm has been fitted except when dicing. Check that the

bowl is not full and the outlet is not blocked.

6.2.5 - The machine stops operating:

Check that the food to be cut is not frozen or too hard and that the voltage

supplied is in accordance with the voltage indicated on the technical plate (Fig.

No 19).

6.2.6 - The microswitches on the pusher lever and the cover do not work:

Check that they are not blocked by dirt or other materials.

6.2.7 - The machine will not start:

Check that all the safety devices are correctly positioned (Safety Chapter 1.3).

Check that the machine is plugged into the power supply and that all the relevant

switches in the work place are switched on.

CHAP. 7 - CLEANING THE MACHINE

7.1 - GENERAL

• The machine must be cleaned at least once a day or more often, if necessary.

• All parts of the Vegetable Preparation Machine which come into direct or

indirect contact with the food for cutting must be meticulously cleaned.

Before carrying out any operations it is necessary to:

• disconnect the plug from the power supply to completely insolate the machine

from the rest of the equipment.

Be careful of the residual risks from the cutting parts and / or associated

parts during cleaning or handling the discs.

7.2 - PRODUCTS TO BE USED

The machine must be wiped with normal detergents at room temperature, using a

damp cloth.