32

Refrigeration System

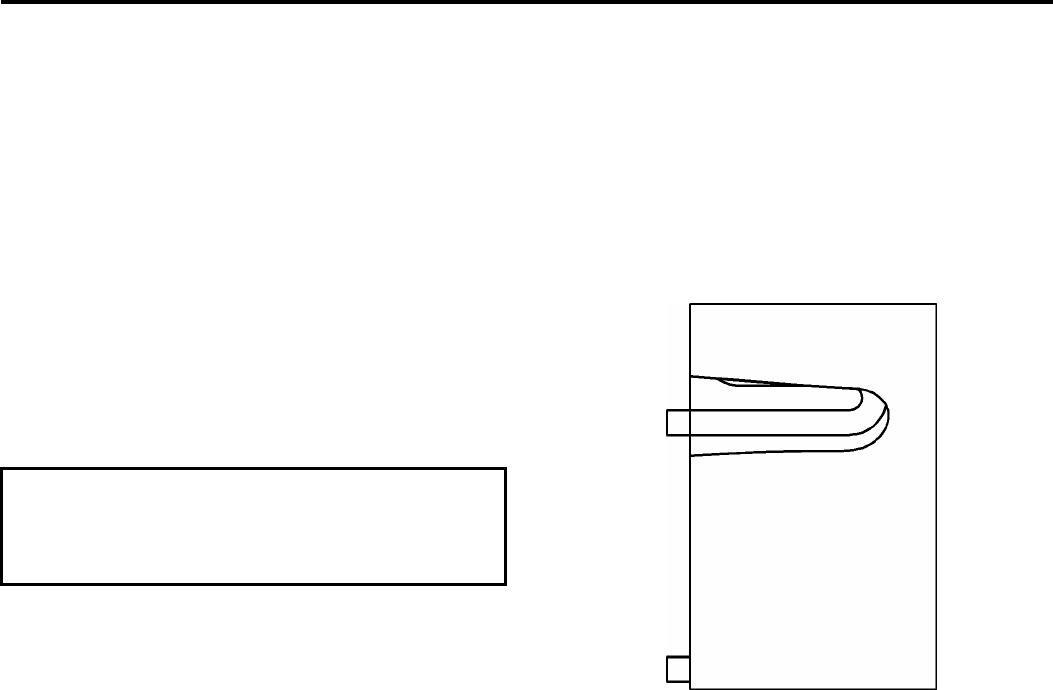

ICE FORMATION PATTERN 2. Extremely Thin at Evaporator Outlet

Evaporator ice formation pattern analysis is helpful

in ice machine diagnostics.

There is no ice, or a considerable lack of ice

formation on the top of the evaporator (tubing

outlet).

Analyzing the ice formation pattern alone cannot

diagnose an ice machine malfunction. However,

when this analysis is used along with Manitowoc’s

Refrigeration System Operational Analysis Table, it

can help diagnose an ice machine malfunction.

Examples: No ice at all on the top of the evaporator,

but ice forms on the bottom half of the evaporator.

Or, the ice at the top of the evaporator reaches 1/8”

to initiate a harvest, but the bottom of the

evaporator already has 1/2” to 1” of ice formation.

Improper ice formation can be caused by any

number of problems.

Example: An ice formation that is “extremely thin

on top” could be caused by a hot water supply, a

dump valve leaking water, a faulty water fill valve,

a low refrigerant charge, etc.

Important

Keep the water curtain in place while checking

the ice formation pattern to ensure no water is

lost.

1. Normal Ice Formation

Ice forms across the entire evaporator surface.

At the beginning of the freeze cycle, it may appear

that more ice is forming on the bottom of the

evaporator than on the top. At the end of the freeze

cycle, ice formation on the top will be close to, or

just a bit thinner than, ice formation on the bottom.

The dimples in the cubes at the top of the

evaporator may be more pronounced than those on

the bottom. This is normal.

SV1576

ICE

ICE

OUTLET

INLET

Extremely Thin Ice Formation

At Evaporator Outlet

The ice thickness probe must be set to maintain the

ice bridge thickness at approximately 1/8”. If ice

forms uniformly across the evaporator surface, but

does not reach 1/8” in the proper amount of time,

this is still considered normal.