Electrical System Section 6

6-54

Part No. 80-1214-3

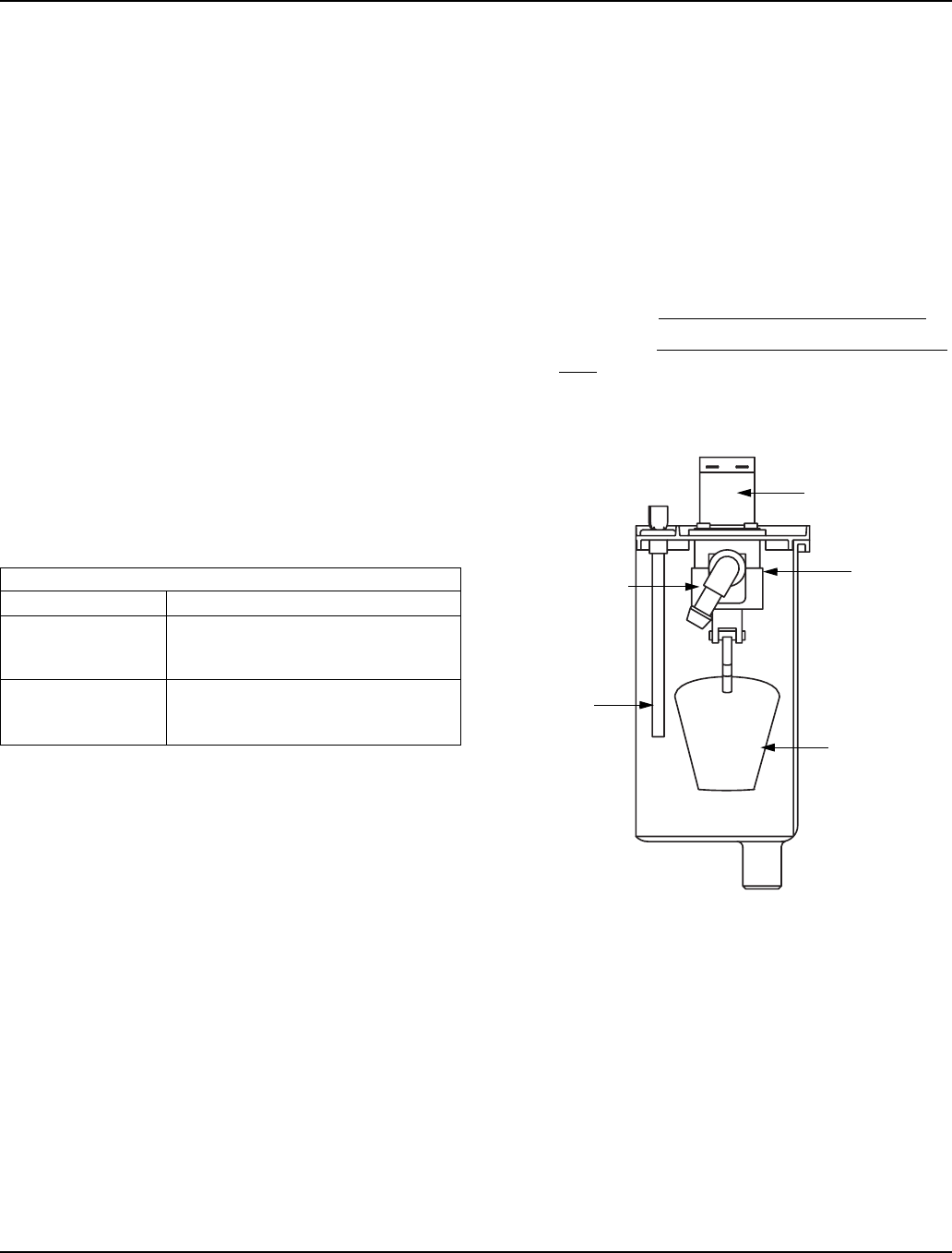

WATER FLOAT VALVE

Function

The float valve maintains correct water level during the

Freeze cycle.

It allows the evaporator to drain completely during the

Automatic Shut-Off cycle.

Check Procedure

1. Verify water is supplied to the float valve, the water

inlet screen is clean, and the float and float arm are

free moving.

2. Refer to the Energized Parts Chart and verify the

following:

• The float valve coil should be energized.

• The red water valve LED on the control board is

energized.

3. Check for line voltage at float valve coil. This test

must be performed within 90 seconds of the water

float valve energizing. If no water contacts the water

level probes within 90 seconds, the valve will de-

energize.

WATER LEVEL CHECK

The float valve maintains the correct water level. The

water level must allow the water level probes to maintain

water contact throughout the Freeze cycle. The water

level is factory set and normally will not require

adjustment. Check the water level during the Freeze

cycle. The water level is correct if the Water Level

indicator light is energized and no water is entering the

overflow tube. (Check for overflow water exiting the ice

machine drain line at the floor drain.)

If adjustments are necessary:

A. Rotate float clockwise to increase water level

.

B. Rotate float counterclockwise to decrease water

level

.

Verify the outlet for the water float valve is at a 20° to 30°

angle to prevent contact with the float.

Step 3 Check for Line Voltage

Voltage Reading Result

Line Voltage

Replace Solenoid Coil

or

Replace Valve

No Voltage

See

“Control Board Relays”

for further diagnostics.

WATER FLOAT

VALVE SOLENOID

COIL

VERIFY WATER

OUTLET DOES

NOT POINT

STRAIGHT DOWN;

IT MAY

INTERFERE WITH

FLOAT.

WATER FLOAT

VALVE

WATER LEVEL

PROBE

WATER FLOAT

ROTATE TO

ADJUST WATER

LEVEL.

Revised 8/2003