Refrigeration System Section 7

7-12

Part Number 80-1632-3

ANALYZING DISCHARGE PRESSURE

DURING FREEZE OR HARVEST CYCLE

Procedure

1. Determine the ice machine operating conditions:

Air temp. entering condenser ______

Air temp. around ice machine ______

Water temp. entering sump trough ______

2. Refer to Operating Pressure Chart for ice machine

being checked.

Use the operating conditions determined in step 1 to

find the published normal discharge pressures.

Freeze Cycle _______ Harvest Cycle _______

3. Perform an actual discharge pressure check.

4. Compare the actual discharge pressure (step 3) with

the published discharge pressure (step 2).

The discharge pressure is normal when the actual

pressure falls within the published pressure range for the

ice machine’s operating conditions.

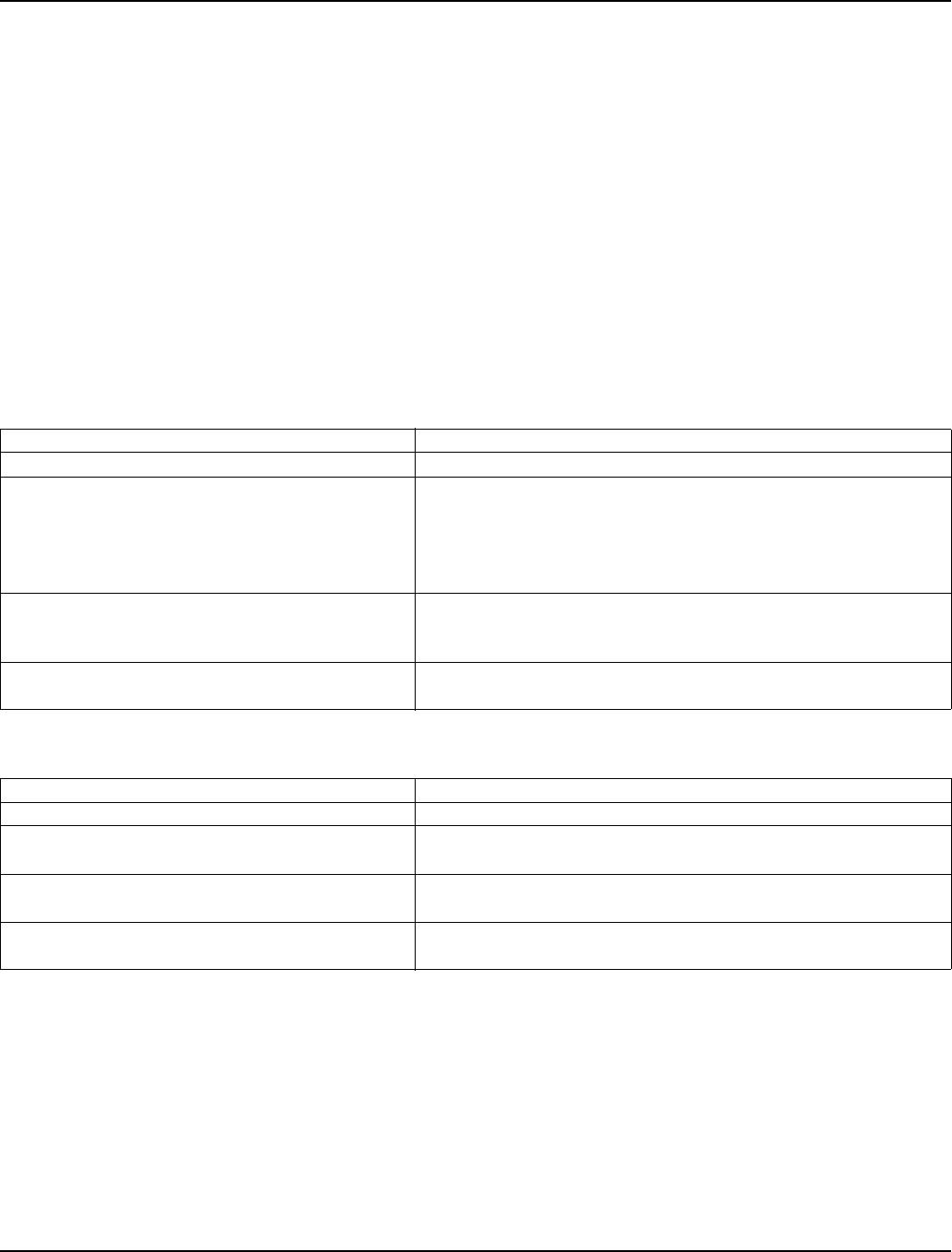

Freeze Cycle Discharge Pressure High Checklist

Freeze Cycle Discharge Pressure Low Checklist

NOTE: Do not limit your diagnosis to only the items listed in the checklists.

Freeze Cycle

PSIG (kPa)

Harvest Cycle

PSIG (kPa)

Beginning of Cycle __________ __________

Middle of Cycle __________ __________

End of Cycle __________ __________

Possible Cause Check/Correct

Improper installation See “Installation/Visual Inspection Checklist”

Restricted condenser water flow (water-cooled

models)

Low water pressure [20 psi (138 kPa) min.]

High inlet water temperature (90°F/32.2°C max.)

Dirty condenser

Dirty/defective water regulating valve

Water regulating valve out of adjustment

Improper refrigerant charge Overcharged

Non-condensables in system

Wrong type of refrigerant

Other Non-Manitowoc components in system

High side refrigerant lines/component restricted (before mid-condenser)

Possible Cause Check/Correct

Improper installation See “Installation/Visual Inspection Checklist”

Improper refrigerant charge Undercharged

Wrong type of refrigerant

Water regulating valve (water-cooled condensers) Out of adjustment

Defective

Other Non-Manitowoc components in system

Defective fan cycle control