Refrigeration System Section 7

7-18

Part Number 80-1632-3

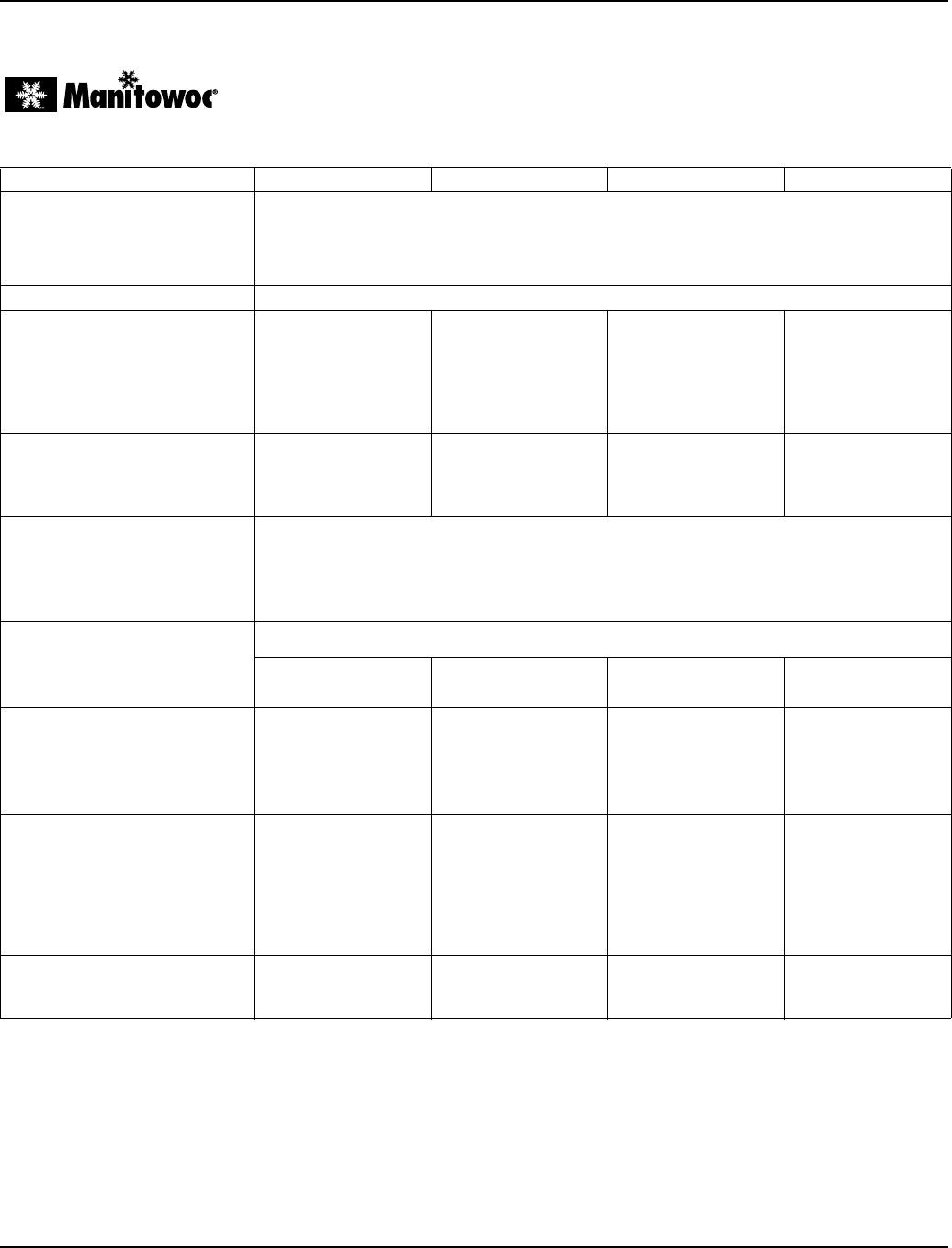

REFRIGERATION SYSTEM OPERATIONAL ANALYSIS TABLES

S Models Dual Expansion Valve - Ice Machine Model Number_________________

This table must be used with charts, checklists and other references to eliminate refrigeration

components not listed on the table and external items and problems, which can cause good

refrigeration components to appear defective.

Operational Analysis 1 2 3 4

Ice Production

Air-Temperature Entering Condenser_____________

Water Temperature Entering Ice Machine_________

Published 24 hour ice production________________

Calculated (actual) ice production_______________

NOTE: The ice machine is operating properly if the ice fill patterns is normal and ice production is within 10% of charted

capacity.

Installation and Water System

All installation and water related problems must be corrected before proceeding with chart.

Ice Formation Pattern

Left Side__________________

Right Side_________________

Ice formation is extremely

thin on outlet of evaporator

-or-

No ice formation on the one

side of evaporator

Ice formation is extremely

thin on outlet of one side of

evaporator

-or-

No ice formation on entire

evaporator

Ice formation normal

-or-

Ice formation is extremely

thin at inlet of one side of

evaporator

-or-

No ice formation on entire

evaporator

Ice formation normal

-or-

No ice formation on entire

evaporator

Safety Limits

Refer to “Analyzing Safety Limits” to

eliminate all non-refrigeration

problems.

Stops on safety limit:

1 or 2

Stops on safety limit:

1 or 2

Stops on safety limit:

1 or 2

Stops on safety limit:

1 or 2

Freeze Cycle

Discharge Pressure

_____ ______ ______

1 minute Middle End

into cycle

If discharge pressure is High or Low refer to freeze cycle high or low discharge pressure problem checklist to eliminate

problems and/or components not listed on this table before proceeding.

Freeze Cycle

Suction Pressure

_____ ______ ______

1 minute Middle End

If suction pressure is High or Low refer to freeze cycle high or low suction pressure problem checklist to eliminate

problems and/or components not listed on this table before proceeding.

Suction pressure is

High

Suction pressure is

Low or Normal

Suction pressure is

High

Suction pressure is

High

Wait 5 minutes into the freeze cycle.

Compare temperatures of

compressor discharge line

and both harvest valve inlets.

One harvest valve inlet is

Hot

-and-

approaches the temperature

of a Hot compressor

discharge line.

Both harvest valve inlets are

Cool enough to hold hand

on

-and-

the compressor discharge

line is Hot.

Both harvest valve inlets are

Cool enough to hold hand

on

-and-

the compressor discharge

line is Cool

enough to hold hand on.

Both harvest valve inlets

are Cool enough to hold

hand on

-and-

the compressor discharge

line is Hot.

Discharge Line Temperature

Record freeze cycle discharge line

temperature at the end of the freeze

cycle

_________°F (°C)

Discharge line temperature

160°F (71.1°C)

or higher at the end of the

freeze cycle

Discharge line temperature

160°F (71.1°C)

or higher at the end of the

freeze cycle

Discharge line temperature

less than

160°F (71.1°C) at the end

of the freeze cycle

Discharge line

temperature 160°F

(71.1°C) or higher at the

end of the freeze cycle

Final Analysis

Enter total number of boxes checked

in each column.

Harvest Valve Leaking

Low On Charge

-Or-

TXV Starving

TXV Flooding Compressor