11

ENGLISH

VIII. GAS SUPPLY

CAUTION

DURING PRESSURE TESTING NOTE ONE OF THE FOLLOW-

ING:

1. The oven and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressure in

excess of 3.45 kPa.

2. The oven must be isolated from the gas supply piping

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressure equal to or less than 3.45 kPa.

3. If incoming pressure is over 50mbar, a separate regu-

lator MUST be installed in the line BEFORE the individual

shutoff valve for the oven.

WARNING: To prevent damage to the control valve regu-

lator during initial turn- on of gas, it is

very important to

open the manual shutoff valve

very slowly.

After the initial gas turn-on, the manual shutoff valve must

remain open except during pressure testing as outlined

in the above steps or when necessary during service

maintenance.

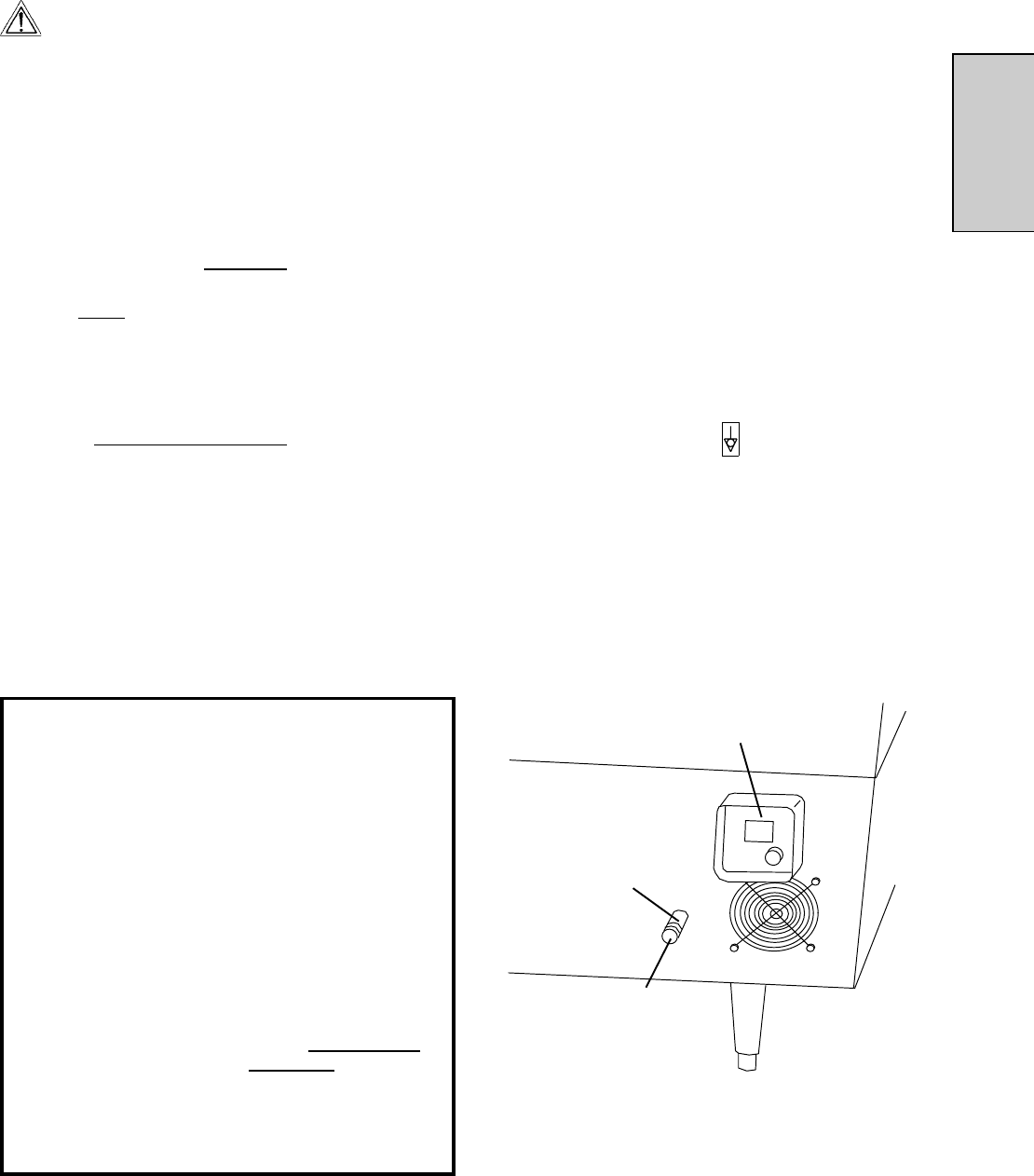

Figure 2-14 - Utility Connection Locations

Electrical

Junction Box

Gas ovens:

19mm pipe for

gas utility connection

Electric ovens:

Cutout for electrical

connection

VII. ELECTRICAL SUPPLY

WARNING

Authorized supplier personnel normally accomplish

the connections for the ventilation system, electric supply,

and gas supply, as arranged by the customer. Following

these connections, the factory-authorized installer can

perform the initial startup of the oven.

NOTE: All aspects of the electrical supply connection must

comply with current IEC/CEE requirements and with all

applicable local, national, and international codes.

Check the oven serial plate before making any electric supply

connections. Electric supply connections must agree with data

on the oven serial plate. The location of the serial plate is shown

in Figure 1-1 (in Section 1,

Description).

A fused disconnect switch or a main circuit breaker (customer

furnished)

MUST be installed in the electric supply line for each

oven cavity. The circuit breaker/disconnect must have 3mm

contact gaps breaking all poles of the supply. It is recommended

that this circuit breaker/disconnect have lockout/tagout capability.

The supply conductors are to be 90°C-rated copper wiring.

Additional wiring information is shown on the wiring diagrams

in Section 5,

Electrical Wiring Diagrams and inside the machin-

ery compartment of the oven.

The oven requires a ground connection to the oven ground

screw located in the electrical junction box. (The box is shown

in Figure 2-14.) The ground connection must comply with

current IEC/CEE requirements and with all applicable local,

national, and international codes. If necessary, have the

electrician supply the ground wire. Do NOT use the wiring

conduit or other piping for ground connections!

A. Additional Information - Gas Ovens

All electric supply connections are made via the electrical

junction box on the rear of the oven, shown in Figure 2-14. The

power lines then connect to the oven circuits through safety

switches located inside the machinery compartment and each

blower motor compartment. These switches interrupt electric

power to the oven when the Machinery Compartment Access

Panel is opened, OR when either of the blower or rear shrouds

is removed.

B. Additional Information - Electric Ovens

A cutout in the back wall of the machinery compartment provides

access to the electrical supply connections. See Figure 2-14.

The actual wiring connections are made at the electrical junction

box.

C. Connection

Refer to the wiring diagram inside the machinery compartment,

or in Section 5 of this Manual, to determine the correct

connections for the electrical supply lines. Connect the supply

as indicated on the wiring diagram.

If required by national or local codes, connect an equipotential

ground wire to the lug next to the

symbol. The equipotential

ground connection must meet all applicable national and lo-

cal code requirements.

SECTION 2 - INSTALLATION