12

ENGLISH

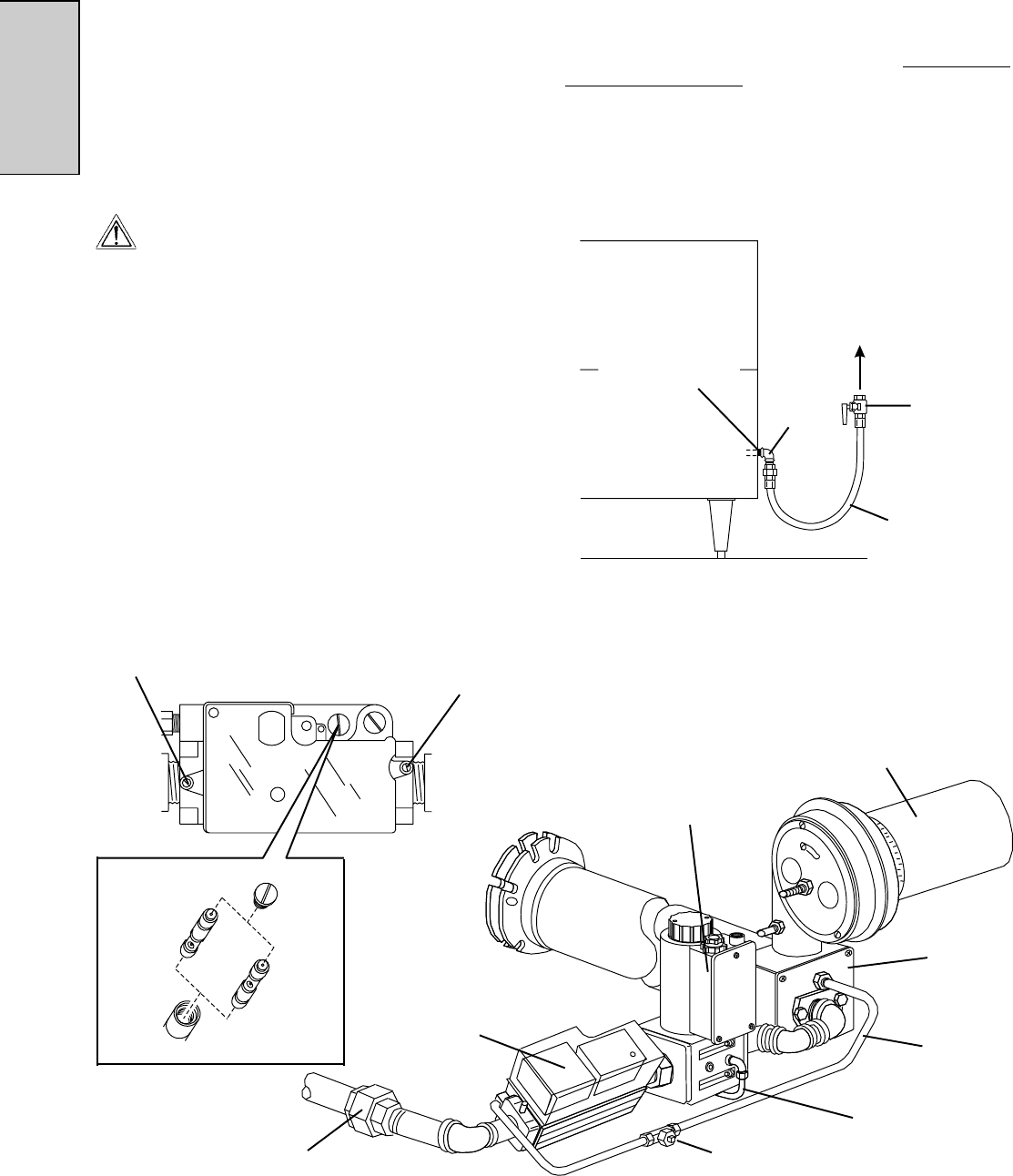

Figure 2-16 - Gas Burner and Piping Assembly

Multifunction

Gas Valve

A. Gas Utility Rough-In Recommendations

The following gas system specifications are STRONGLY

RECOMMENDED. Deviating from these recommendations

may affect the baking performance of the oven.

Gas Meter

One or two oven cavities: 354

l/sec

meter

Three or four oven cavities: 566

l/sec

meter

Gas Line

DEDICATED LINE from the gas meter to the oven

50.8mm pipe for natural gas

38.1mm pipe for propane

Maximum length: 61m. Each 90° elbow equals 2.13m of

pipe.

B. Connection

WARNING

Some procedures in this section may require conver-

sions, readjustments, or service on the oven's gas system.

Before performing these procedures, check that the main

gas supply valve and the circuit breaker/fused disconnect

are in the OFF ("O") position. After completing these proce-

dures, perform a gas leak test before operating the oven.

CAUTION

The terms of the oven's warranty require all start-ups, conver-

sions and service work to be performed by a Middleby Marshall

Authorized Service Agent. The installation, start-up and changes

required when changing from one gas type to another can be

performed ONLY by a certified professional.

NOTE: The gas supply connection should be according to

applicable ISO 228-1 or ISO 7-1 recommendations. All aspects

of the gas supply connection must comply with current IEC/CEE

requirements and with all applicable local, national, and inter-

national codes.

Check the ovens gas supply requirements before making the

gas utility connection. Gas supply requirements are listed on

the ovens serial plate.

Check the serial plate to determine the type of gas to be used

with the oven. Check that the gas type indicated matches the

local supply at the installation. If the gas type on the serial plate

does NOT match the local supply, directions for converting the

oven for use with other gases are described in

Preparation for

Use with Various Gases, in this section.

Refer to the instructions in the gas hose package (included in

the Installation Kit) before connecting the gas line. One gas line

connection method is shown in Figure 2-15; however,

compliance with the applicable standards and regulations is

mandatory.

Orifice

(manifold)

pressure tap

Governor

disabled for

liquid

propane (LP)

operation

Governor

enabled for

natural gas

operation

Pilot pressure tap

Low Flame

Bypass Line

High Flame

Solenoid Valve

Gas Burner

Burner Blower

Supply (inlet)

pressure tap

Union

Pilot Line

Multifunction Gas Valve

Figure 2-15 - Flexible Gas Hose Installation

Appliance

Connection/Male

Nipple

Flexible

Gas Hose

Full-Flow Gas

Shutoff Valve

To Gas

Supply Pipe

90°

Elbow

SECTION 2 - INSTALLATION