20

ENGLISH

II. MAINTENANCE - MONTHLY

A. Check that the oven is cool and the power is disconnected,

as described in the warning at the beginning of this Section.

B. Remove the crumb trays, drive motor shroud, and conveyor

extension covers from the oven.

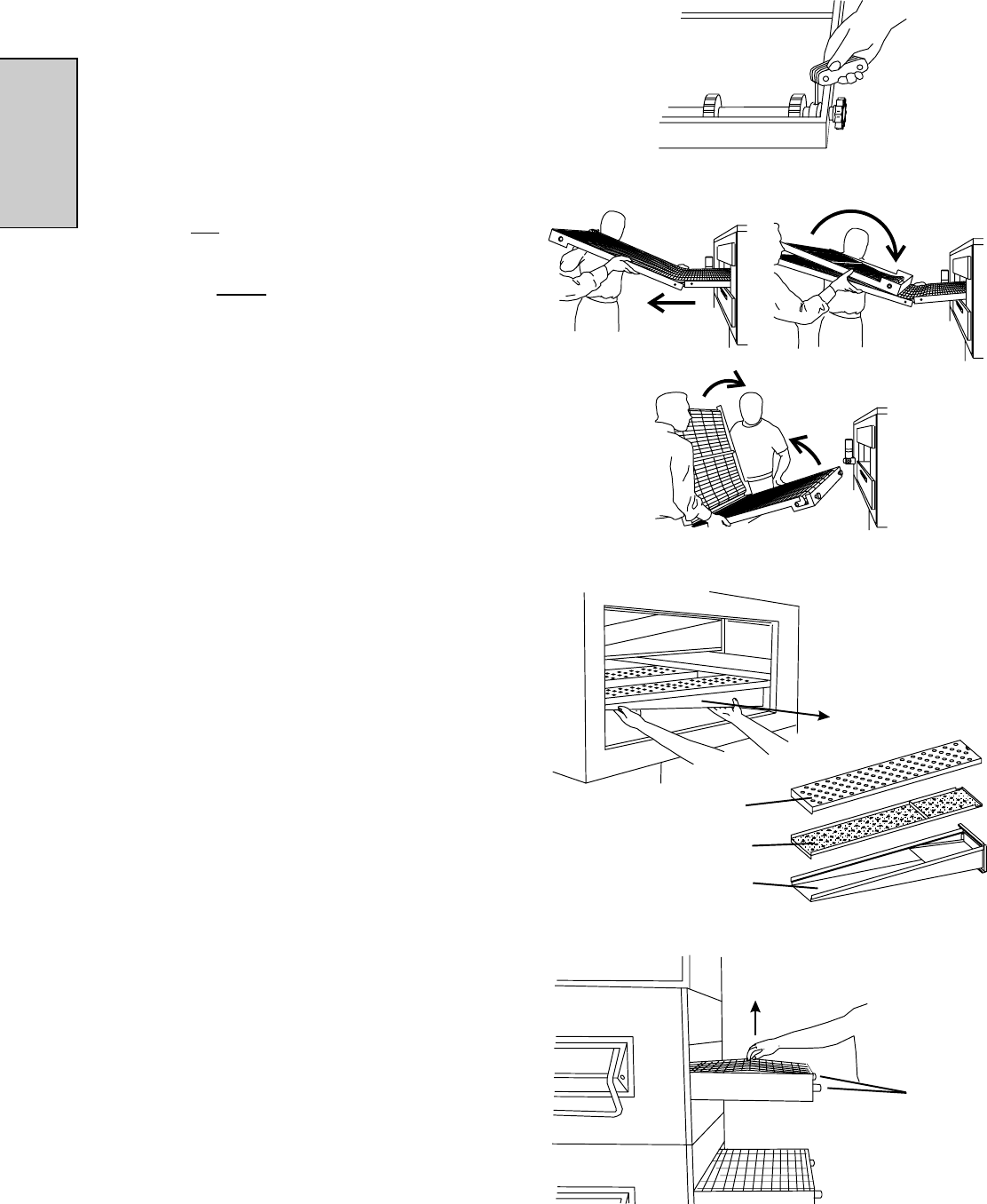

C. Lift the drive end of the conveyor slightly, and push it forward

into the oven. This removes the tension from the drive

chain. Then, remove the drive chain from the conveyor

sprocket.

NOTE

Split belt conveyors can only be removed from the end of

the oven

with the drive motor.

Single-belt conveyor assemblies may be removed from

either end of the oven. If it is to be removed from the end

of the oven

without the drive motor, the drive sprocket

assembly must be removed.

To remove the drive sprocket (if necessary), loosen the set

screw on the conveyor collar as shown in Figure 4-2. Then,

pull the sprocket assembly straight out.

D. Slide the conveyor out of the oven, folding it as it is removed.

See Figure 4-3.

E. Remove the end plugs from the oven.

F. Slide the air fingers and blank plates out of the oven, as

shown in Figure 4-4. AS EACH FINGER OR PLATE IS

REMOVED, WRITE A "LOCATION CODE" ON IT WITH A

MARKER to make sure that it can be reinstalled correctly.

Example of markings:

(Top Row) T1 T2 T3 T4 T5 T6

(Bottom Row) B1 B2 B3 B4 B5 B6

G. Disassemble the air fingers as shown in Figure 4-4. AS

EACH FINGER IS DISASSEMBLED, WRITE THE "LOCA-

TION CODE" FOR THE FINGER ON ALL THREE OF ITS

PIECES. This will help you in correctly reassembling the

air fingers.

CAUTION

Incorrect reassembly of the air fingers will change the

baking properties of the oven.

H. Clean the air finger components and the interior of the

baking chamber using a vacuum cleaner and a damp cloth.

Refer to the boxed warnings at the beginning of this Section

for cleaning precautions.

I. Reassemble the air fingers. Then, replace them in the

oven, using the "location code" as a guide.

J. Replace the end plugs on the oven.

K. Reassemble the conveyor into the oven. If the drive sprocket

was removed when installing the conveyor, replace it at this

time.

L. Reattach the drive chain.

M. Check the tension of the conveyor belt as shown in Figure

4-5. The belt should lift between 75-100mm. DO NOT

OVERTIGHTEN THE CONVEYOR BELT. If necessary, the

belt tension can be adjusted by turning the conveyor adjust-

ment screws, located at the idler (right) end of the conveyor.

N. Replace the conveyor extension covers, drive motor shroud,

and crumb trays.

Figure 4-3 - Removing the Conveyor

Figure 4-4 - Removing Air Fingers and Plates

Figure 4-2 - Removing the Conveyor Drive Sprocket

Loosen conveyor collar

set screw, then pull

sprocket straight out

Figure 4-5 - Checking the conveyor tension

75-100mm

vertical

deflection

Conveyor

tension

adjustment

screws (idler

end only)

Manifold

Inner plate

Outer plate

SECTION 4 - MAINTENANCE