9

ENGLISH

SECTION 2 - INSTALLATION

V. CONVEYOR INSTALLATION

NOTE

Split belt conveyors can only be installed from the end of the

oven

with the drive motor.

Single-belt conveyor assemblies may be inserted into either

end of the oven. If it is to be installed from the end of the oven

without the drive motor, the drive sprocket assembly must be

removed.

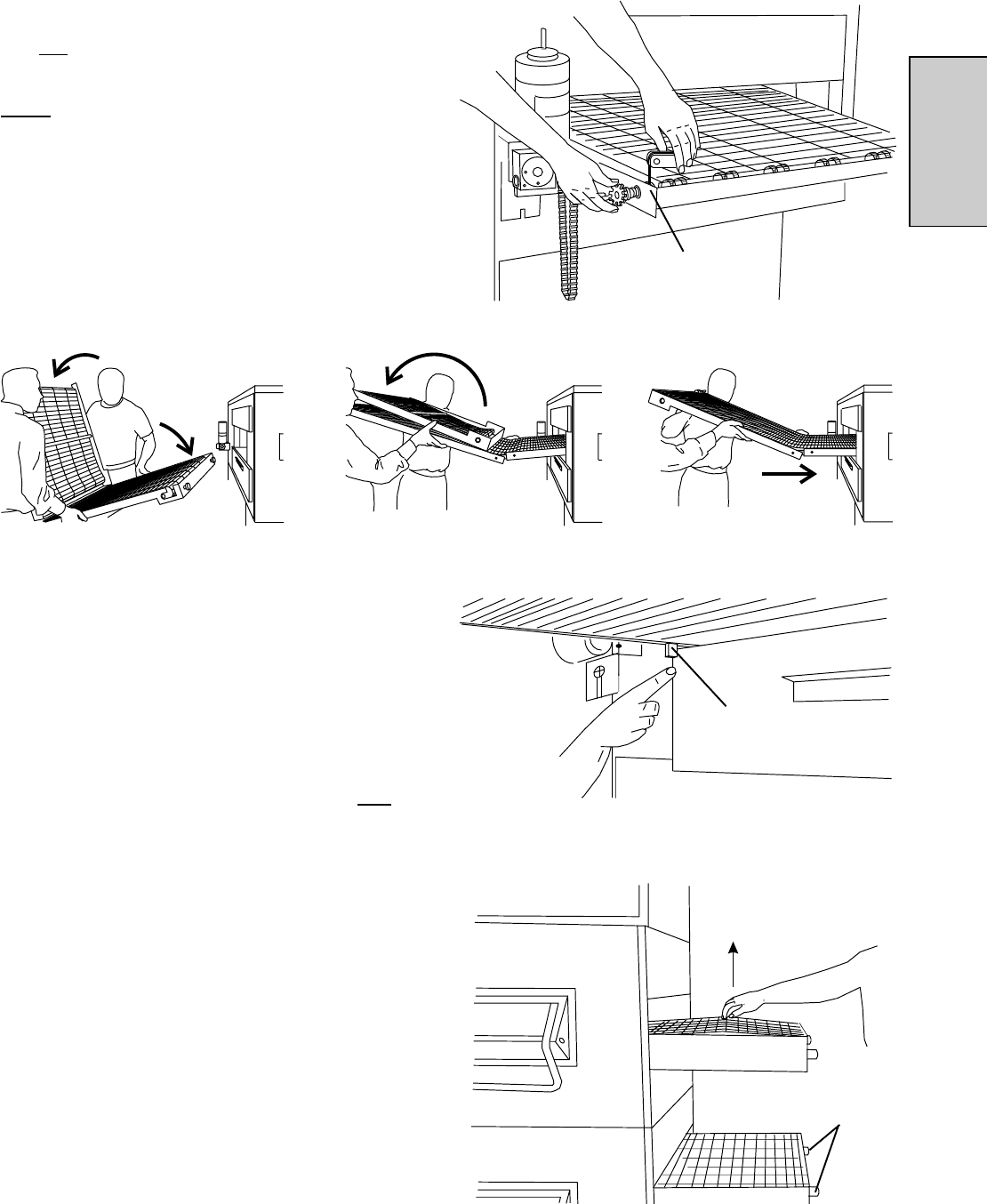

To remove the drive sprocket (if necessary), loosen the set

screw on the conveyor collar as shown in Figure 2-7. Then, pull

the sprocket assembly straight out.

1. Lift the conveyor and position it in the oven as shown in

Figure 2-8.

Figure 2-8 - Inserting the Conveyor

2. Continue moving the conveyor into the oven until the frame

protrudes equally from each end of the oven (about 457mm).

3. Check that the retainers located on the underside of the

conveyor frame rest firmly against the lower end plug, as

shown in Figure 2-9.

NOTE:

Each oven has retainer clips on the bottom of the conveyor

frame, as shown in Figure 2-9. The clips are only located

on the left (drive) side of the frame.

4. When the conveyor is positioned properly, check for free-

dom of movement of the conveyor belt by pulling it for about

60 to 90 cm with your fingers. The conveyor

must move

freely.

5. If the drive sprocket was removed when installing the

conveyor, replace it at this time.

6. Install the drive chain between the conveyor drive sprocket

and the motor sprocket. To install the chain, it will be

necessary to lift the drive end of the conveyor slightly. The

drive motor and sprocket are shown in Figure 2-7.

7. Install the conveyor drive motor cover and tighten its hanger

screw (on the rear wall of the oven).

8. Check the tension of the conveyor belt as shown in Figure

2-10. The belt should lift between 75-100mm. DO NOT

OVERTIGHTEN THE CONVEYOR BELT.

NOTE:

If necessary, the belt tension can be adjusted by turning the

conveyor adjustment screws, located at the idler (right) end

of the conveyor. See Figure 2-10.

Figure 2-9 - Conveyor retainers

Figure 2-10 - Checking the conveyor tension

75-100mm

vertical

deflection

Retainer clip

Figure 2-7 - Removing the Conveyor Drive Sprocket

Loosen conveyor collar

set screw, then pull shaft

straight out

Conveyor

tension

adjustment

screws (idler

end only)