10

ENGLISH

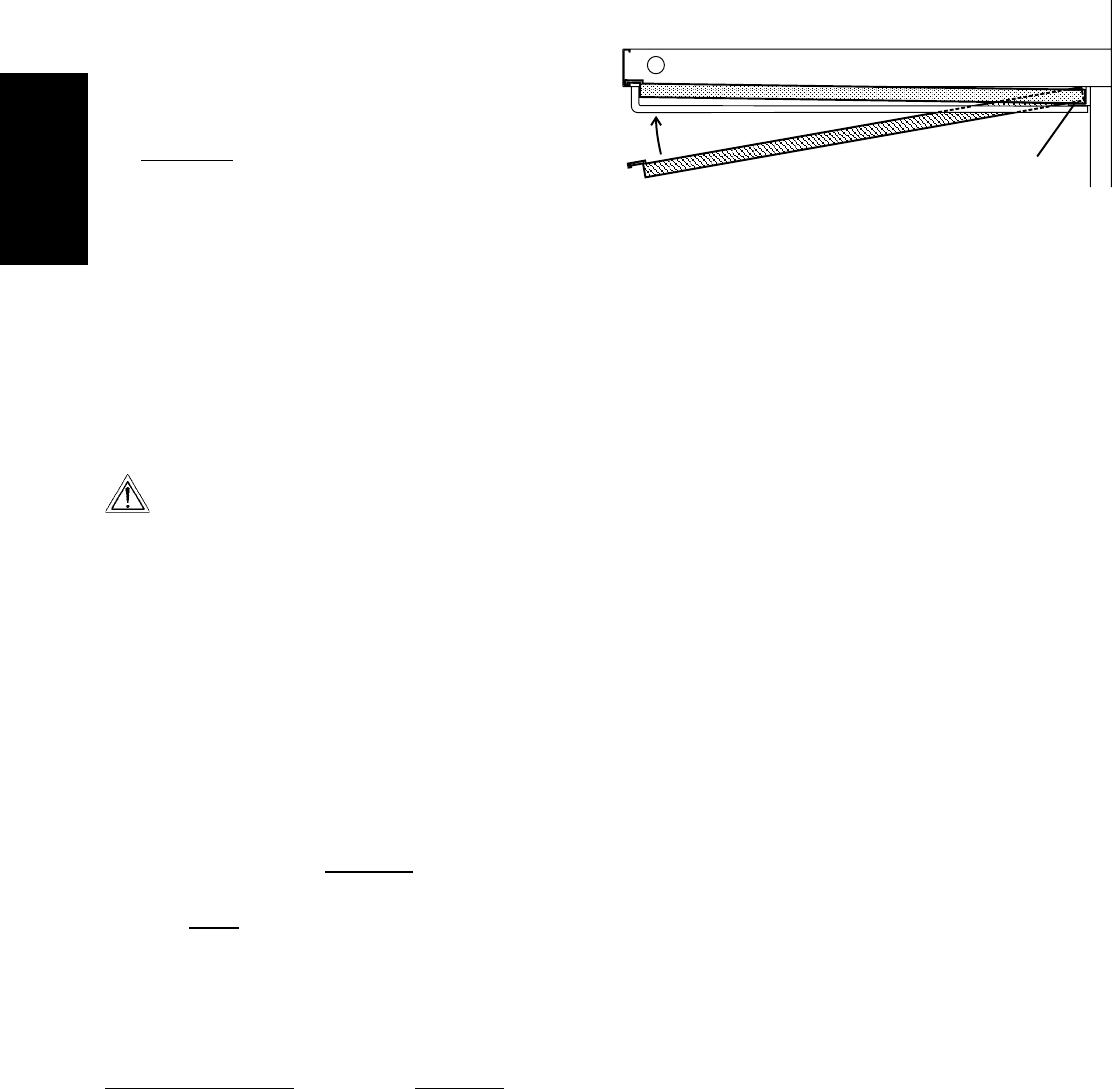

Figure 2-12 - Crumb trays

Swing outside

edge of tray

up and into

place

Place inside

edge of tray on

retainer bracket

SECTION 2 - INSTALLATION

VI. ELECTRICAL SUPPLY

WARNING

Authorized supplier personnel normally accomplish

the connections for the ventilation system, electric supply,

and gas supply, as arranged by the customer. Following

these connections, the factory-authorized installer can

perform the initial startup of the oven.

NOTE: The electric supply installation must satisfy the

requirements of the appropriate statutory authority, such as the

National Electrical Code (NEC), ANSI/NFPA70, (U.S.A.); the

Canadian Electrical Code, CSA C22.2; the Australian Code

AG601; or other applicable regulations.

NOTE: The electric supply connection must meet all national

and local electrical code requirements.

Check the oven serial plate before making any electric supply

connections. Electric supply connections must agree with data

on the oven serial plate. The location of the serial plate is shown

in Figure 1-1 (in Section 1,

Description).

A fused disconnect switch or a main circuit breaker (customer

furnished)

MUST be installed in the electric supply line for each

oven cavity. It is recommended that this switch/circuit breaker

have lockout/tagout capability.

The supply conductors must be of the size and material (cop-

per) recommended. Refer to the wiring diagram inside the

machinery compartment of the oven. Electrical specifications

are also listed on the oven's serial plate and in Table 1-4,

Electrical Specifications (in Section 1, Description).

The oven requires a ground connection to the oven ground

screw. For gas ovens, the ground screw is located in the

electrical junction box (see Figure 2-13). For electric ovens, the

ground screw is located inside the side compartment of the

oven (see Figure 2-14). If necessary, have the electrician supply

the ground wire. Do NOT use the wiring conduit or other piping

for ground connections!

V. FINAL ASSEMBLY

1. Install the crumb trays underneath the conveyor as shown

in Figure 2-12. First, place the inside edge of the tray onto

the retainer (shown in Figure 2-9). Then, swing the outside

edge of the tray up and into place.

2. Press the conveyor end stop and rear stop down over the

edge of the conveyor frame. See Figure 1-1 (in Section 1,

Description).

A. Additional Information - Gas Ovens

Incoming electrical power lines are fed through the strain-

relief fitting, shown in Figure 2-13. The electrical supply

connections are made inside the electrical junction box.

The power lines then connect to the oven circuits through

safety switches located inside the machinery compart-

ment and each blower motor compartment. These switches

interrupt electric power to the oven when the Machinery

Compartment Access Panel is opened, OR when either of

the blower or rear shrouds is removed.

B. Additional Information - Electric Ovens

A 2" (51mm) dia. cutout in the back wall of the machinery

compartment provides access to the electrical supply

connections. The actual wiring connections are made at

the terminal block located inside the side compartment of

the oven.

Using flexible cables for the electric power supply

conductors requires a 2" (51mm) strain-relief fitting (not

furnished with the oven) to enable safe access to the

terminal block.

C. Connection

Refer to the wiring diagram inside the machinery

compartment of the oven to determine the correct

connections for the electrical supply lines. Connect the

supply as indicated on the wiring diagram.

CAUTION

The terms of the oven's warranty require all start-ups, conver-

sions and service work to be performed by a Middleby Marshall

Authorized Service Agent.