12

Adjustments

Disconnect machine from

power source, shut off air supply and bleed

residual air from system, before making

adjustments. Failure to comply may cause

serious injury.

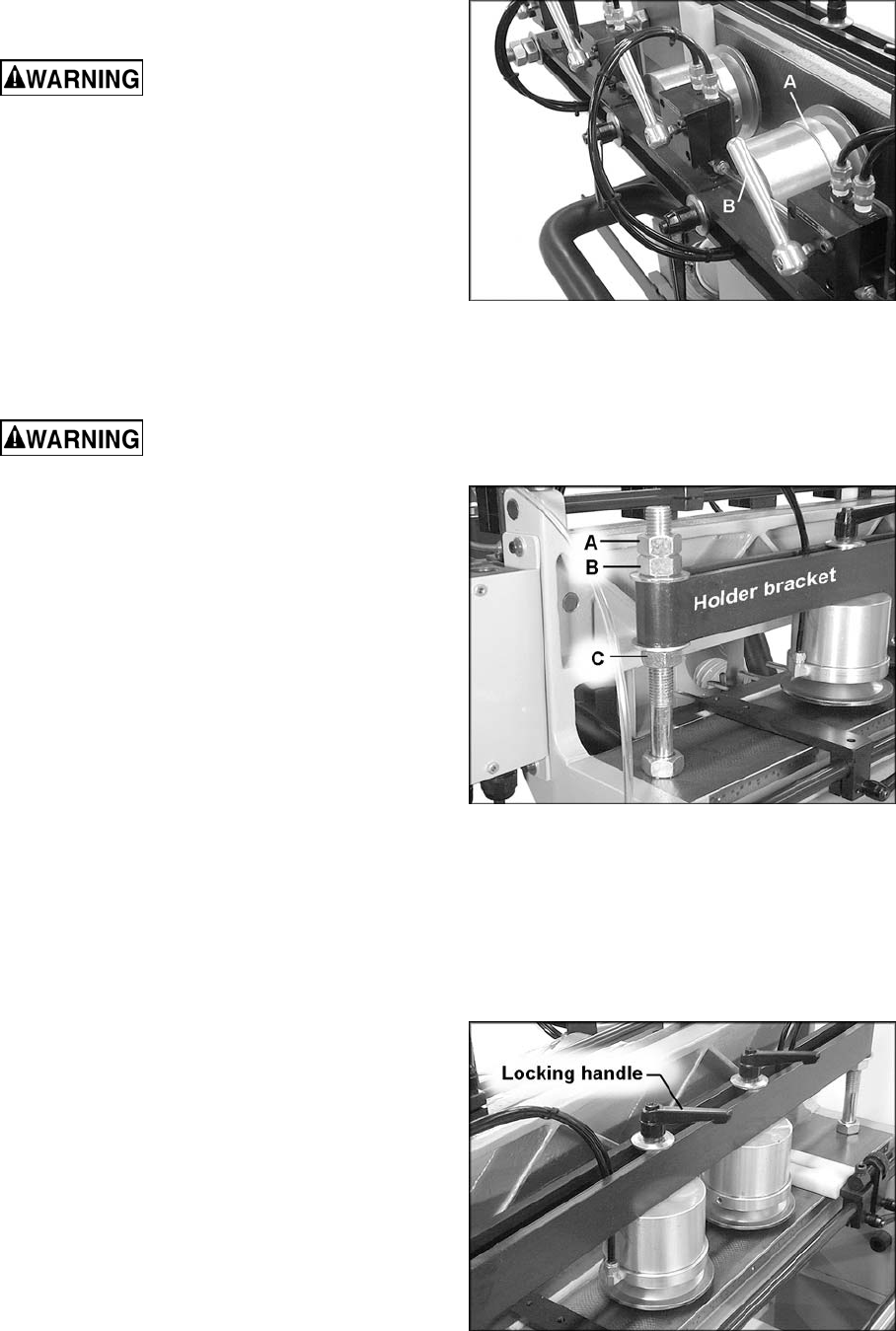

Clamping Cylinders

The workpieces are clamped to the table by

pneumatically operated aluminum cylinders (A,

Figure 9). Each cylinder has its own air on/off

lever. Simply turn the lever (B, Figure 9) to “on”

position to activate the cylinder; the cylinder will

respond immediately by clamping the workpiece

against the table.

Always keep fingers out of

the way of clamping cylinders. Failure to

comply may cause serious injury.

Both vertical and horizontal clamping cylinders

can be adjusted to match the thickness of your

workpieces. To change the thickness capacity of

the clamping cylinders, proceed as follows:

1. To increase the clamping capacity, loosen

the top two hex nuts (A and B, Figure 10) on

the stud at the end of the holder bracket,

with a 30mm wrench. Do the same for the

stud at the opposite end of the holder

bracket.

2. Tighten the lower hex nut (C, Figure 10).

You can do this without a wrench. This will

raise the holder bracket. Do this

incrementally on both studs until the desired

height is reached. When finished, tighten

top hex nuts (A & B, Figure 10) on both

studs with the wrench.

NOTE: Make equal adjustment on both studs at

each end of the holder bracket to ensure the

clamps are parallel to the table. To check this,

measure from the bottom edge of the holder

bracket down to the table. Measure at each end

of the holder bracket – the measurements

should be equal. Figure 10 shows the horizontal

clamping assembly - the procedure is identical

for the vertical clamping assembly.

3. To decrease the clamping capacity, back off

the lower hex nut (C, Figure 10) and tighten

the top hex nut (B, Figure 10). This will

lower the holder bracket.

4. When finished, tighten the lower hex nut (C)

against the holder bracket, and bring hex

nut (A) down against hex nut (B).

Figure 9

Figure 10

Figure 11