25

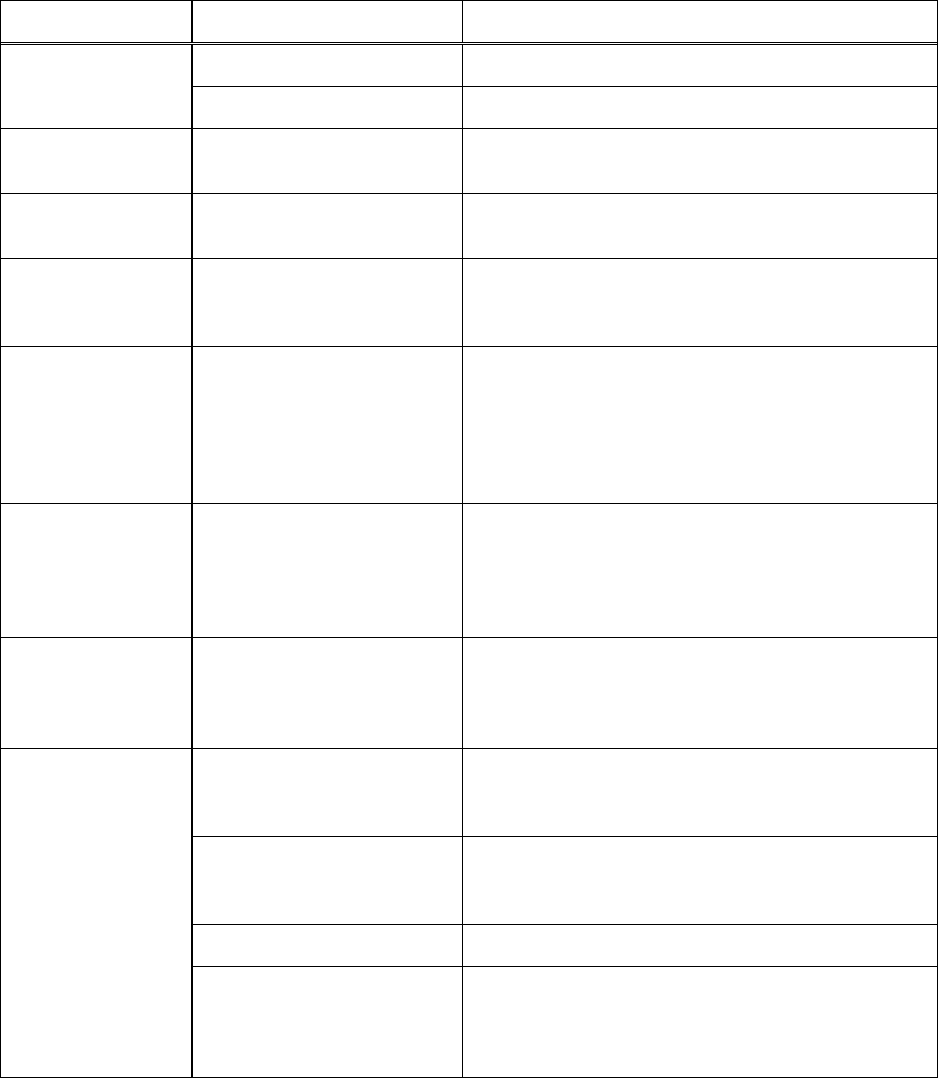

Trouble Probable Cause Remedy

Cutter not cutting

properly.

Cutter in wrong position. Turn cutter towards the (+) or (-) mark [page 18].

Cutter dull or damaged. Sharpen or replace cutter [page 19].

Dovetailed parts fit

too tightly.

Cutter not adjusted

properly.

Loosen set screws and turn cutter toward the (+)

mark. Retighten set screws [page 18].

Dovetailed parts fit

too loosely.

Cutter not adjusted

properly.

Loosen set screws and turn cutter toward the (-)

mark. Retighten set screws [page 18].

Cutter sometimes

slips and misses

revolutions.

Drive belt tension incorrect. Adjust drive belt tension [page 19].

Dovetailed parts fit

side to side, but

have depth gaps

between the

mortise and tenon

cuts.

The mortise depth or tenon

thickness is set incorrectly.

Change depth of mortise cut or thickness of tenon

cut by using the adjustment screw [page 17 & 18].

A gap between

mortise and tenon

cuts increases

along the

dovetailed corner.

Boards not square when

clamped.

Make sure the initial cuts on the board (ripping

and/or crosscutting) have been done squarely, and

that the board is flush against the stop before

clamping.

Side piece edge is

not aligned with

front/back piece

edge.

Fences not set correctly. Offset the vertical fence from the horizontal fence

by half the pitch of the cut [page 16].

Workpiece slips

during the cut.

Clamping cylinder not

positioned over center of

workpiece.

Position clamping cylinder to take advantage of its

full surface area [page 13].

Clamping cylinder too high

to properly contact

workpiece.

Lower clamping cylinder in relation to thickness of

workpiece [page 12].

Clamping pressure too low. Adjust pressure at air regulator [page 13].

Surface area of workpiece

too small to achieve

adequate coverage from

clamping cylinder.

Use larger workpiece.