13

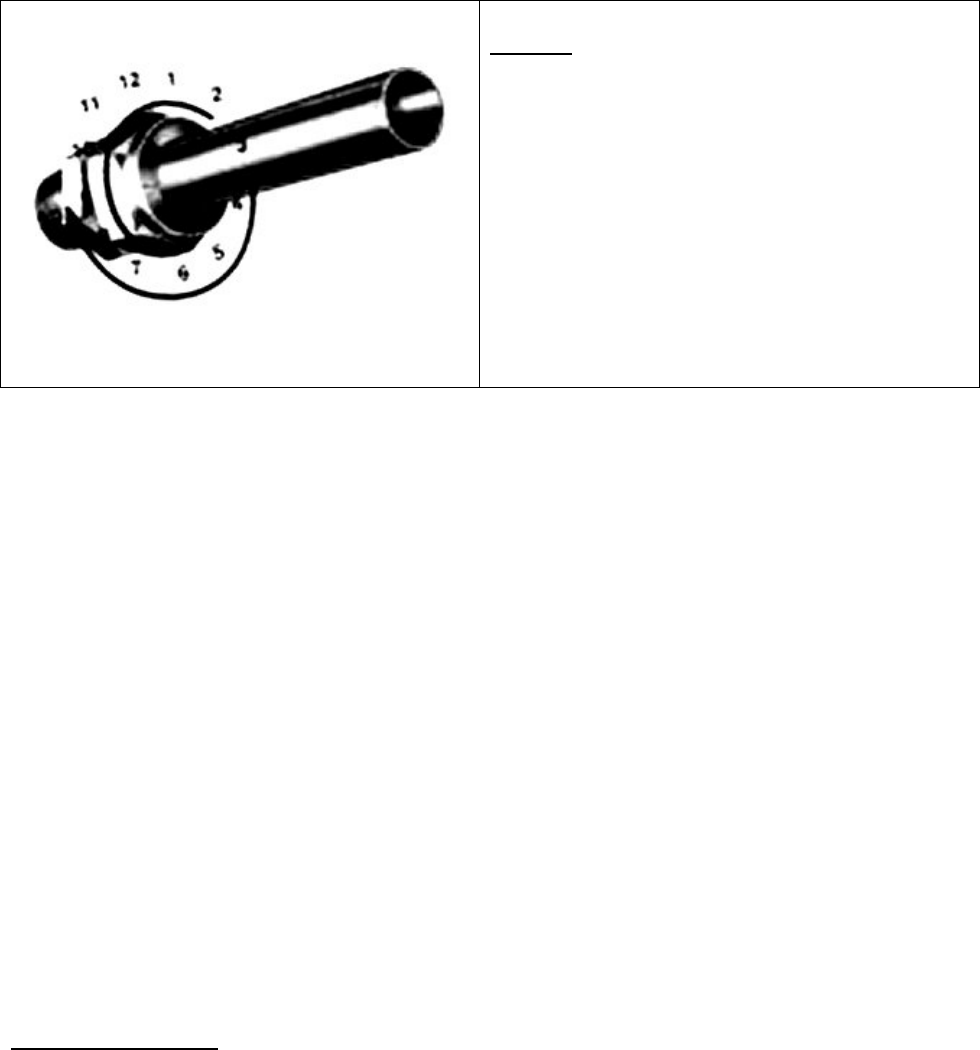

STEP 3

Now, while holding the fitting body steady

with a backup wrench, tighten the nut 1 1/4

turns. Watch the scribe mark, make one

complete revolution and continue to the 9

o'clock position. By scribing the nut at the 6

o'clock position as it appears to you, there

will be no doubt as to the starting position.

When tightened 1 1/4 turns to the 9 o'clock

position you can easily see that the fitting

has been properly installed.

* SWAGELOK FITTINGS ARE TO BE TIGHTENED TO A TORQUE SPEC, NOT

INFINITE TIGHTNESS. BE SURE YOUR STARTING POINT IS WRENCH SNUG.

(SEE STEP 4 on page 12.) A DISTORTED TUBE MIGHT GIVE A FALSE STARTING

POINT.

* Swagelok fittings have a built-in spring interaction between the ferrules. This

compensates for temperature changes and allows the fittings to be reconnected many

times. As the fitting is tightened, a burnishing occurs between the body of the fitting and

the ferrules and between the ferrules and the tube. This action provides the tightest

connection available.

* When making all connections, USE TWO WRENCHES. Don't allow the fittings to turn

or twist when tightening.

RECONNECTING PRE-SWAGED FITTINGS

Connections can be disconnected and retightened many times.

When reconnecting, insert the tubing with pre-swaged ferrules into the fitting until the

front ferrule seats in the fitting. Tighten the nut by hand to prevent cross threading.

Tighten the nut one-quarter of a turn with a wrench (or to original one-and-one-quarter

tight position). Then snug slightly with the wrench. No more than an additional 1/8 turn.