HRX-OM-J049-A

Chapter 3 Transport and Installation

HRG010-W HRG015-W 3.2 Installation

1st edition : Aug. 2006

Rev. A: May. 2007

3-13

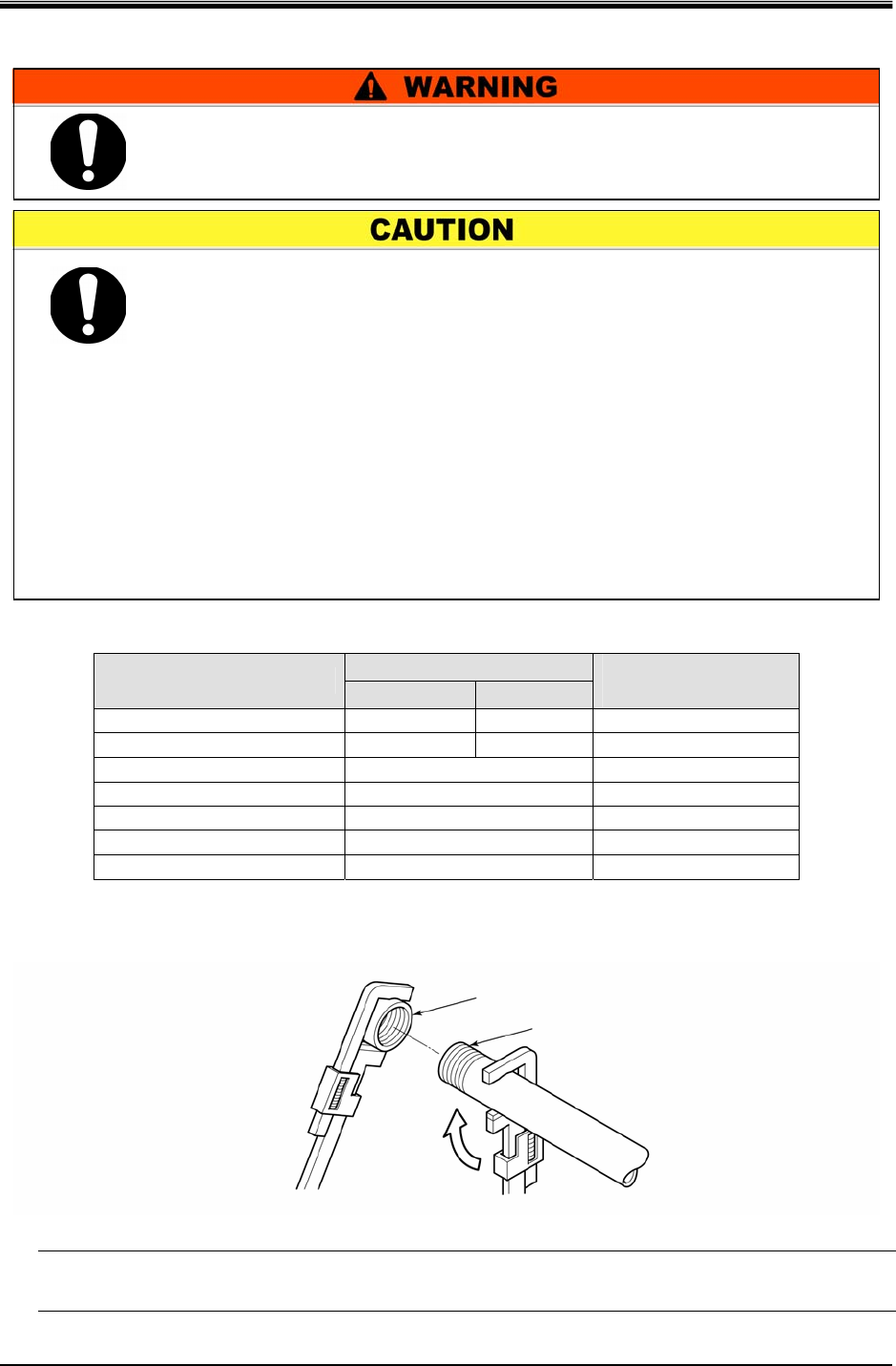

Pipe coupling hole

Sealant

Fig. 3-12 Tightening of Pipe

3.2.6 Piping

Pipe diameter

Table 3-5 Pipe diameter

Diameter

Pipe

HRG010-W HRG015-W

Recommended

tightening torque

Facility water IN Rc1/2 Rc3/4

28 to 30N·• m

Facility water OUT Rc1/2 Rc3/4

28 to 30N·• m

Auto supply port Rc1/2

28 to 30N·• m

Circulating fluid OUT Rc3/4

28 to 30N·• m

Circulating fluid RETURN Rc3/4

28 to 30N·• m

Port for overflow

Rc1/2

28 to 30N·• m

Port for drain in tank Rc1/2

28 to 30N·• m

How to install piping

1. Hold the piping connected port with a specific wrench and tighten the pipe.

[Tips]

Install a valve at the drain port to facilitate the replacing and draining of the circulating fluid from the

tank described in chapter 6 “Unit Maintenance”. (The valve needs to be prepared separately.)

Only expert engineers or personnel who have adequate knowledge of

and experiences with piping installation are allowed to install piping.

Potential fluid leakage or stagnant fluid may occur if disregarded.

z Install piping properly. Failure to conduct proper piping installation

may result in the entry of supplied and drained water into the inside

of the building, which may cause the work area and equipment to

get wet.

z Keep facility water pressure below 0.5MPa.

z Make sure the locations of IN and OUT ports for circulating fluid

supply. The reverse connection inhibits proper operation of the unit.

z Make sure no entry of dust and foreign materials into the water

circuit during piping installation.

z Hold the piping connected port with a pipe wrench when tightening

the pipe. Excessive force will damage the port and cause leaks if

disregarded.

z Hold the piping connected port with a pipe wrench when tightening

piping.